Method and device for simulating multi-rush fracture toughness of well drilling working condition

A technology of fracture toughness and testing device, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, which can solve problems such as inability to simulate, and achieve the effects of ensuring test accuracy, low price, and easy maintenance in the later period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

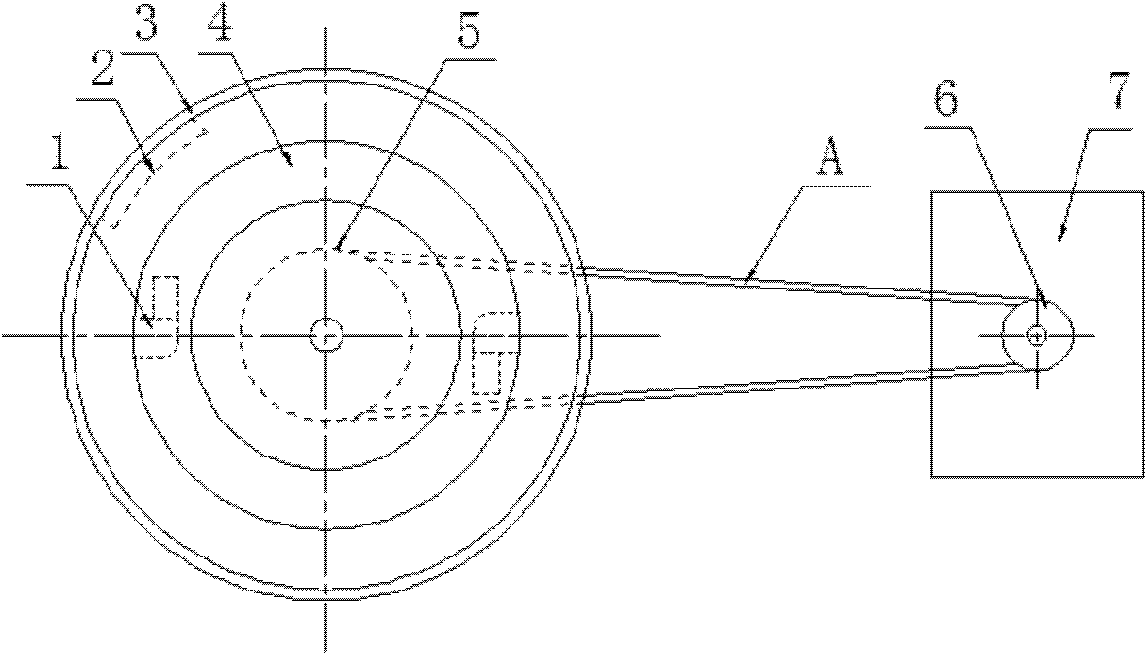

[0024] The invention utilizes the rotation characteristics of the rotating body to make the test piece fixed on the outer edge of the rotating body strike the anvil board adjacent to the rotating body outside the rotating body with a certain period, so as to achieve the low-load multi-stroke fracture toughness test experiment in accordance with the vibration characteristics of the drill string purpose.

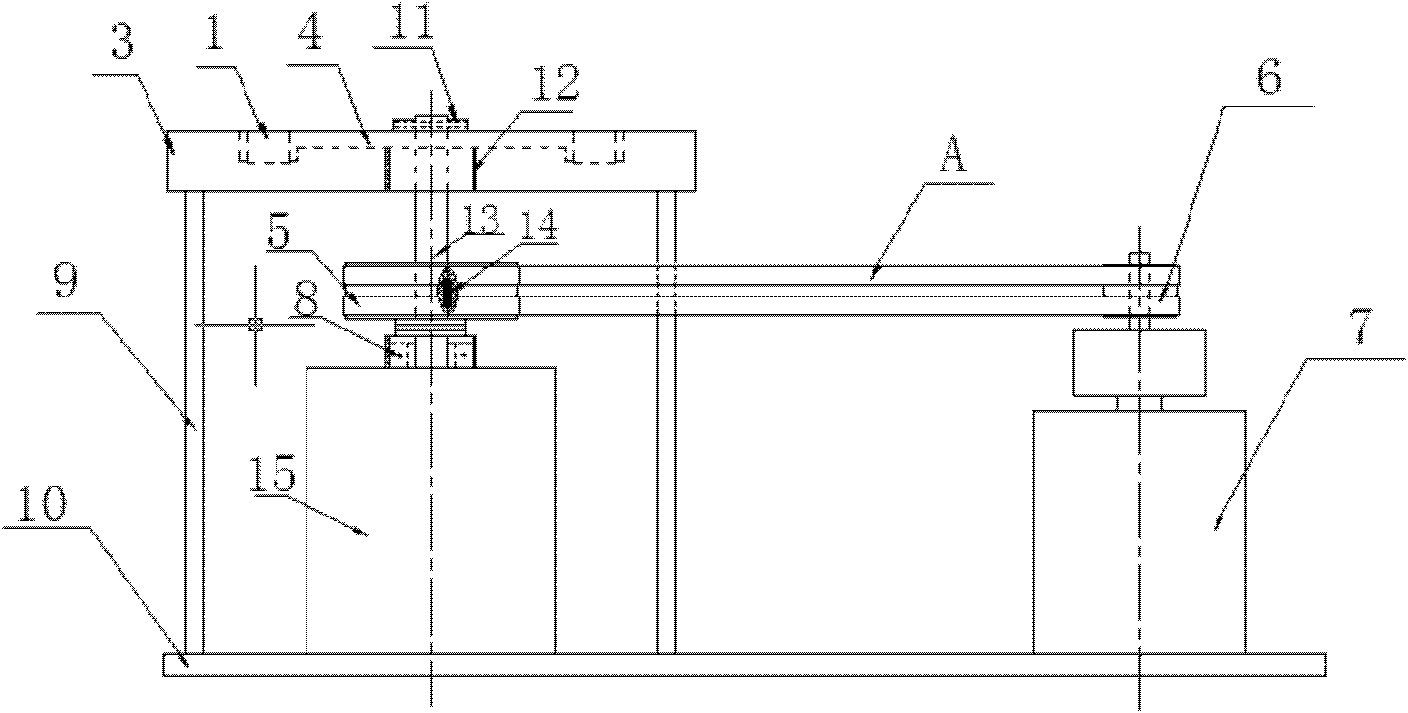

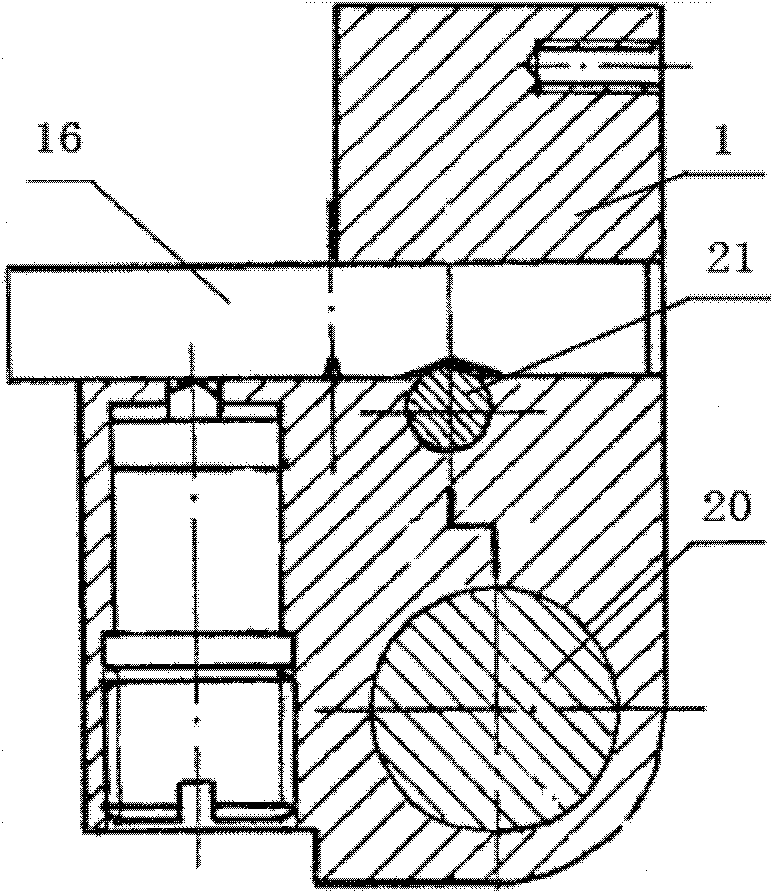

[0025] In order to use the above method, the test device provided by the present invention mainly includes: a base 10, a speed-regulating motor 7, a transmission device A, a mud tank 3, an anvil 2, a rotating main plate 4, and a test piece seat 1. The speed-regulating motor 7 is fixed on the base 10; the transmission device A adopts belt transmission, the power is transmitted to the large pulley 5 through the small pulley 6, the warp shaft 13 drives the rotating main plate 4 to rotate, and the large pulley 5 and the shaft 13 are connected by the key 14; The lower part of 13 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com