Supercharger working state inspection test method

A technology of working status and inspection and testing, which is applied in the testing of machines/structural components, instruments, engines, etc. It can solve problems such as inconsistent output parameters and inability to accurately simulate the practical working conditions of turbochargers, so as to achieve true and reliable data , less time spent, efficient detection of the effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

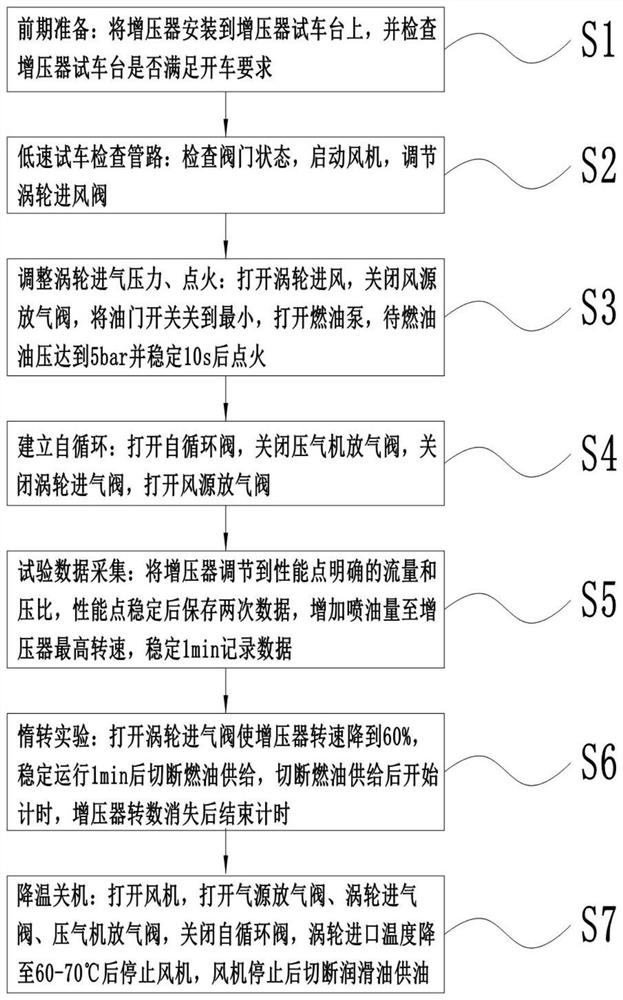

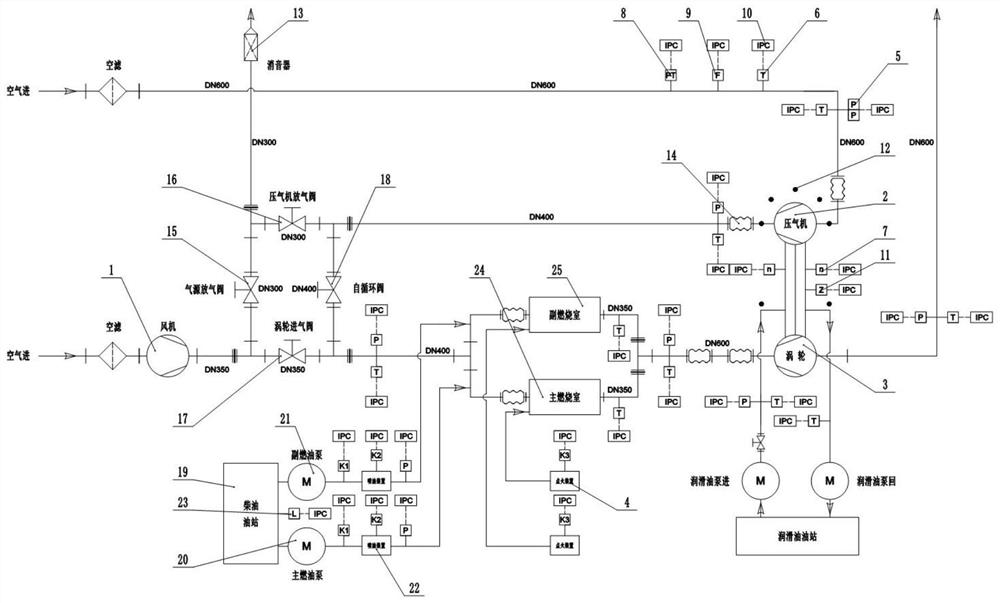

[0026] Basic as attached figure 1 Shown: Supercharger working state inspection test method, using a supercharger test bench for testing, combined with figure 2 As shown, the supercharger test bench includes fan 1, compressor 2, turbine 3, fuel unit, combustion chamber, lubricating oil unit, ignition device 4, several pipelines, several valves, several pressure sensors 5, several temperature sensors 6, Several rotational speed sensors 7, differential pressure sensors 8, flow sensors 9, several control units 10, vibration sensors 11, noise measuring instruments, mufflers 13 and several shock absorbers 14; several pipelines include air intake pipelines, compressors 2 to Combustion chamber pipeline, combustion chamber to turbine 3 pipeline, turbine 3 exhaust pipeline, fuel oil supply pipeline and lubricating oil pipeline; several valves include air source bleed valve 15, compressor bleed valve 16, turbine intake Valve 17 and self-circulation valve 18.

[0027] A pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com