Coal seam strain, seepage, displacement and jet comprehensive test device and method

A comprehensive test and seepage technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as waste of resources, achieve energy saving, avoid energy waste, and save test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

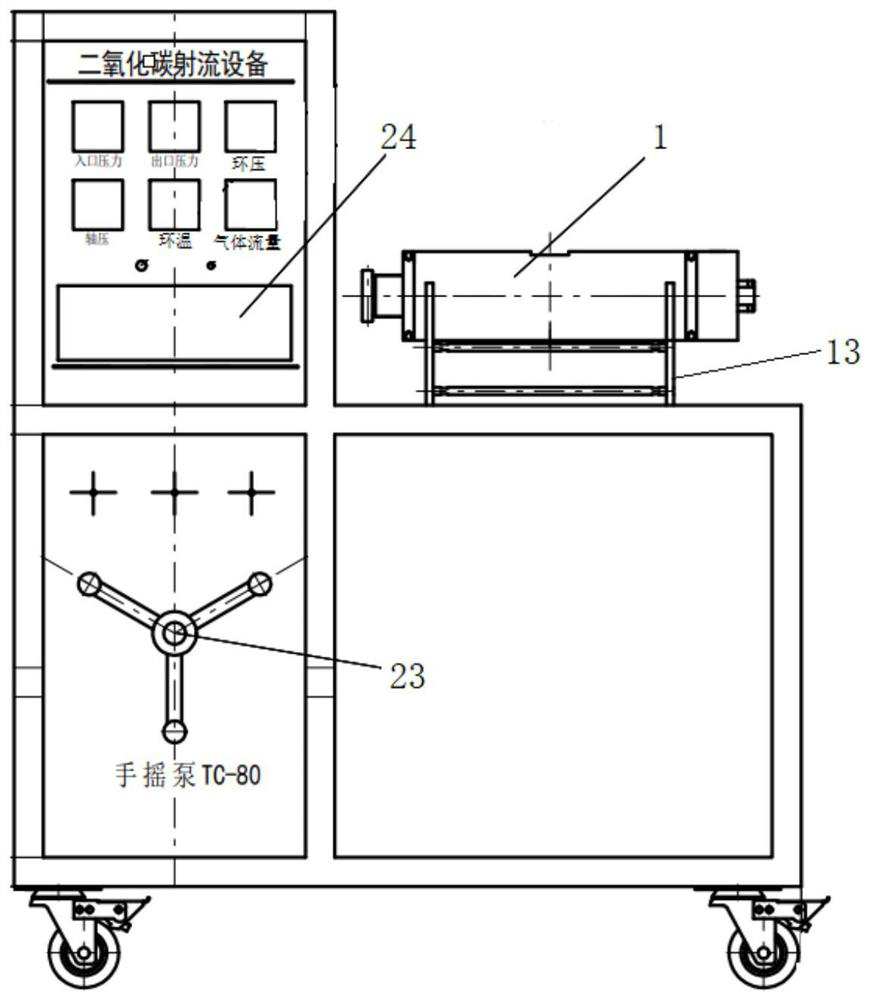

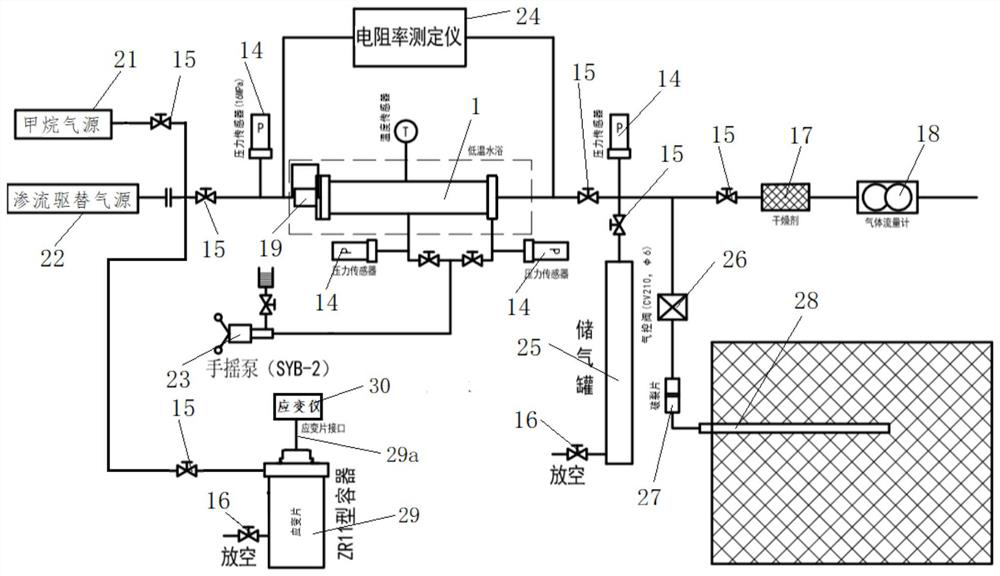

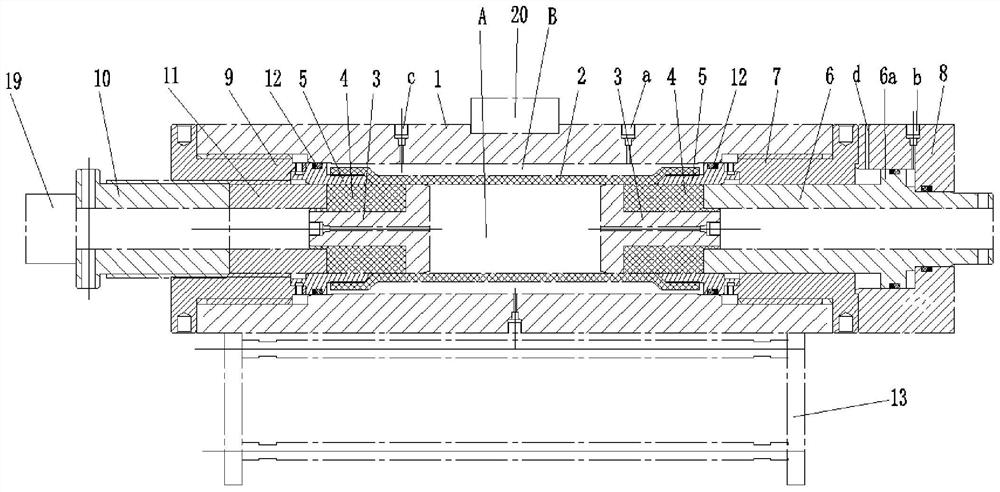

[0035] to combine figure 1 — image 3 As shown, a comprehensive test device for coal seam strain, seepage, displacement and jet flow is mainly composed of a coal heart chamber, a foot 13, a pressure sensor 14, a high pressure valve 15, a vent valve 16, a desiccant 17, a gas flow meter 18, and a vibrator 19 , Ultrasonic generator 20, Methane gas source 21, Seepage displacement gas source 22, Hand pump 23, Resistivity tester 24, Gas storage tank 25, Air control valve 26, Bursting disc assembly 27, Release cylinder 28, Strain measurement The sealed container 29 and the strain gauge 30 are composed.

[0036] Among them, the coal heart chamber is mainly composed of round steel cylinder 1, annular pressure transmission sleeve 2, T-shaped head 3, PEEK sleeve 4, conical steel sleeve 5, right piston sleeve 6, right first pressure sleeve 7, right second pressure sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com