Method for obtaining fracture toughness of material by repeatedly loading and unloading spherical indenter and pressing-in

A spherical indenter and fracture toughness technology, applied in the field of materials, can solve the problems of not considering the damage mechanism of materials, lack of theoretical basis, etc., and achieve good universality, accurate test results, and simple test methods

Active Publication Date: 2018-12-11

SHANDONG UNIV

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with this method is that the stress state under the spherical indenter is considered to be similar to the crack tip of the type I fracture specimen, but this similarity is only shown in the similarity of the absolute value of the stress triaxiality between the two, without considering the tension and compression Different damage mechanisms of materials under stress field

In addition, in this method, the indentation deformation energy of the spherical indenter in the indentation test is equal to the energy required for crack propagation, and there is no theoretical basis.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

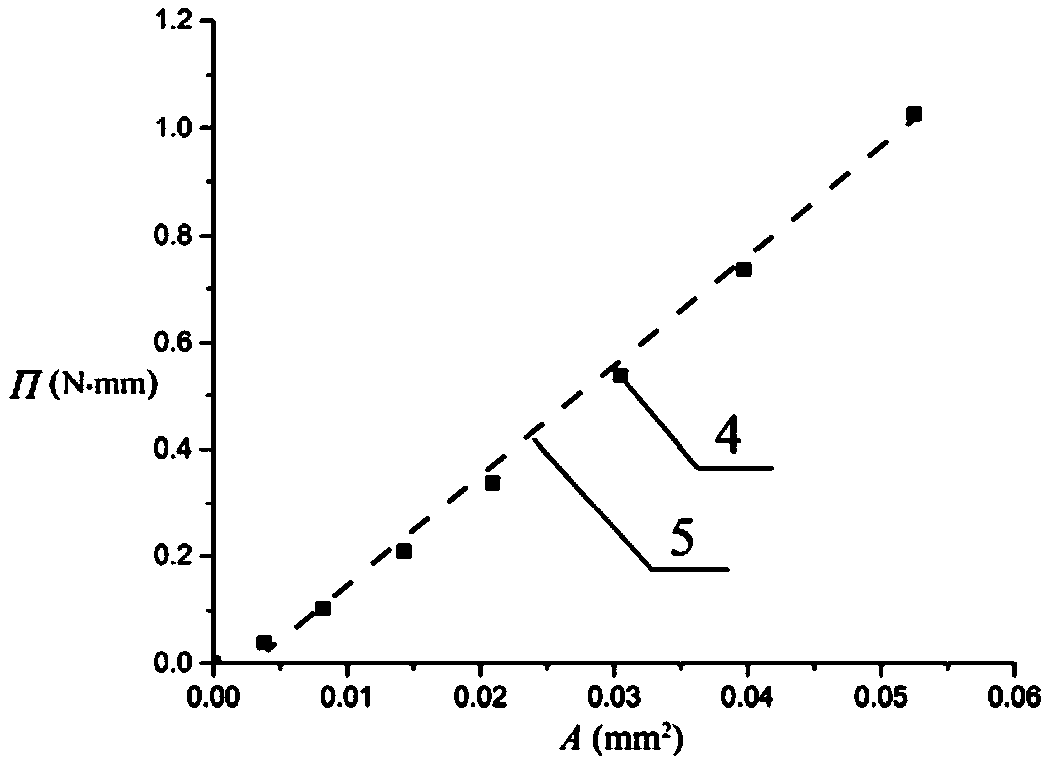

[0053] Embodiment: Apply the method of the present invention to obtain the fracture toughness of SA508 steel

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

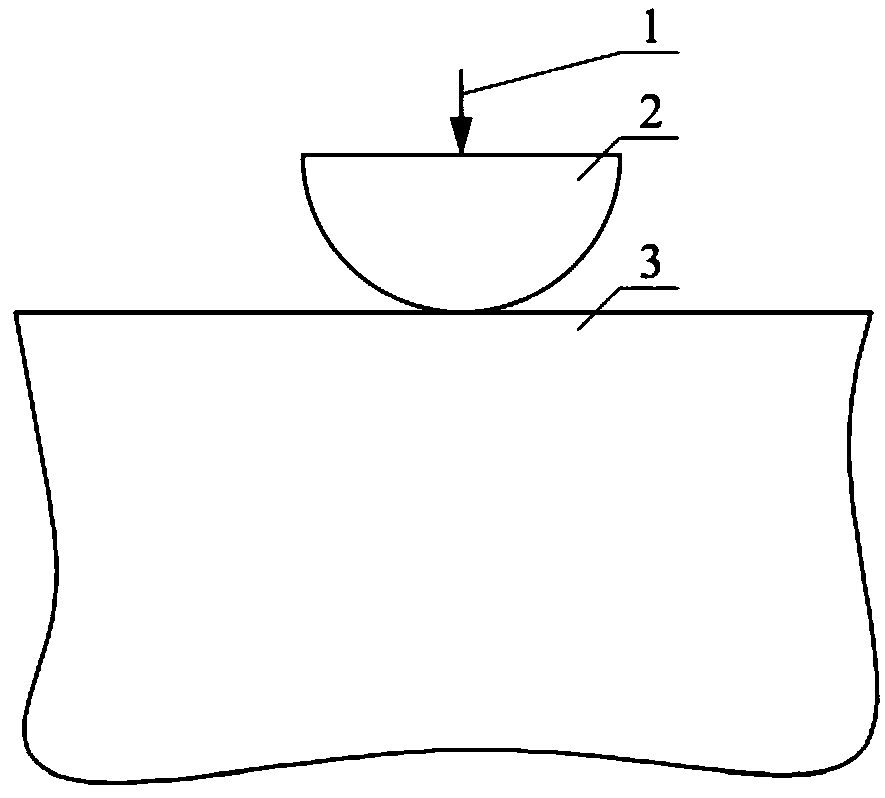

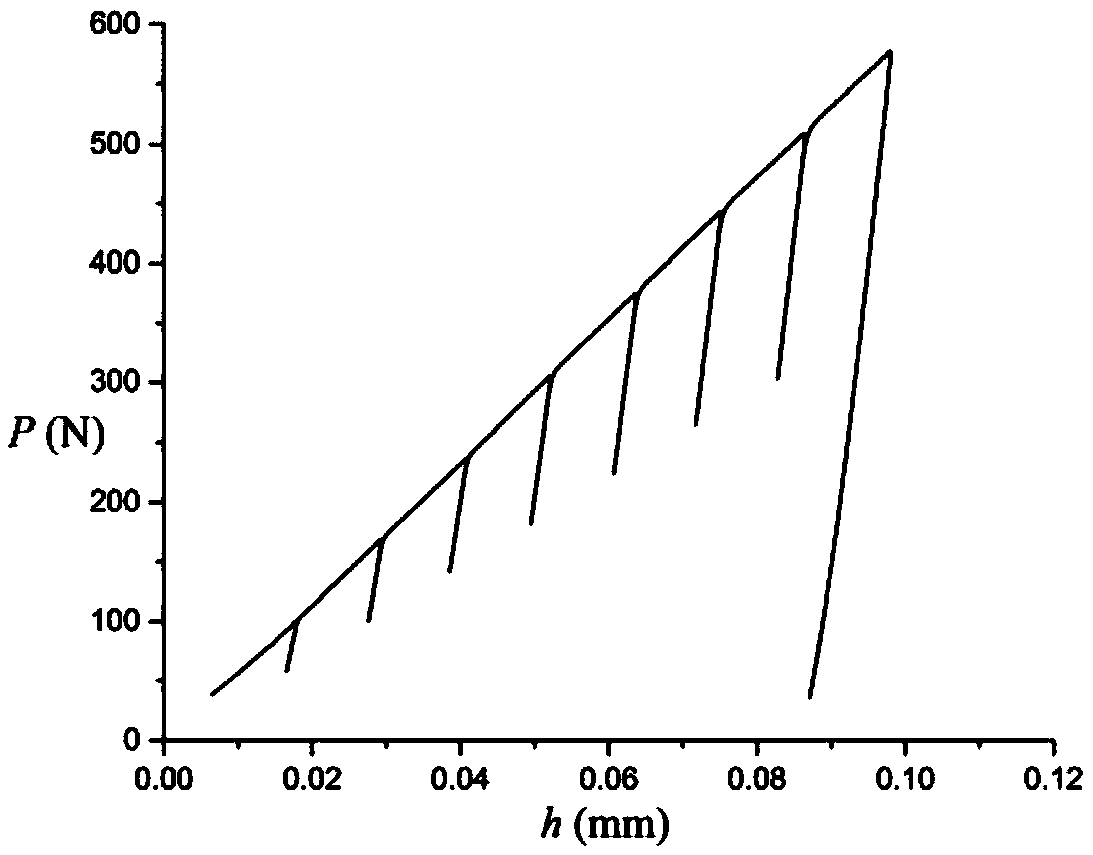

The invention relates to the field of materials, in particular to the filed of new methods for testing mechanical property slight damages of service materials, weld materials and new materials, in particular to a method for obtaining fracture toughness of a material by repeatedly loading and unloading a spherical indenter and pressing-in. The method comprises the steps of: using a spherical indenter of hard material, conducting press-in test on the surface of a smoothed tested material through a method of N times of repeatedly loading and unloading to obtain a continuous indentation load P-indentation depth h curve of the tested material, and then acquiring the fracture toughness of the material through application of the method. The method overcomes the deficiencies that an existing spherical indenter press-in test technology requires an extra destructive uniaxial tensile test or relies on certain materials, and the test method is simple, convenient, and accurate, has good universality, and is beneficial to the popularity and application of the spherical indenter press-in test technology. The method for obtaining the fracture toughness of the material by repeatedly loading and unloading the spherical indenter and pressing-in is suitable for occasions that sampling is difficult to perform according to requirements of a conventional fracture toughness test, especially for the deterioration of material properties of bridges, ships, and the like, and the need to discuss the difference of fracture toughness of local materials.

Description

1. Technical field [0001] The invention relates to the field of new methods for micro-damage testing of mechanical properties of materials, especially service materials, weld materials and new materials, in particular a method for repeatedly loading and unloading a spherical indenter to obtain the fracture toughness of materials. 2. Background technology [0002] As a comprehensive performance of material strength and toughness, fracture toughness is a measure to characterize the ability of materials to resist crack instability expansion, and plays an important role in evaluating the structural integrity of service equipment. However, the traditional fracture toughness test method requires complex test procedures and corresponding instruments and equipment such as destructive sampling from engineering structures or components, standard sample processing, fatigue crack prefabrication and fracture toughness testing, so it cannot be applied to service Fracture toughness testing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/34G01N3/42

CPCG01N3/34G01N3/42

Inventor 王威强张泰瑞王尚张国新

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com