Method for calculating fracture toughness through indentation method

A technology of fracture toughness and indentation method, applied in the direction of applying stable tension/pressure to test material strength, test material hardness, etc., can solve problems such as unreasonable, large errors, and testing, and achieve the effect of low-loss acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention is specifically described below in conjunction with accompanying drawing:

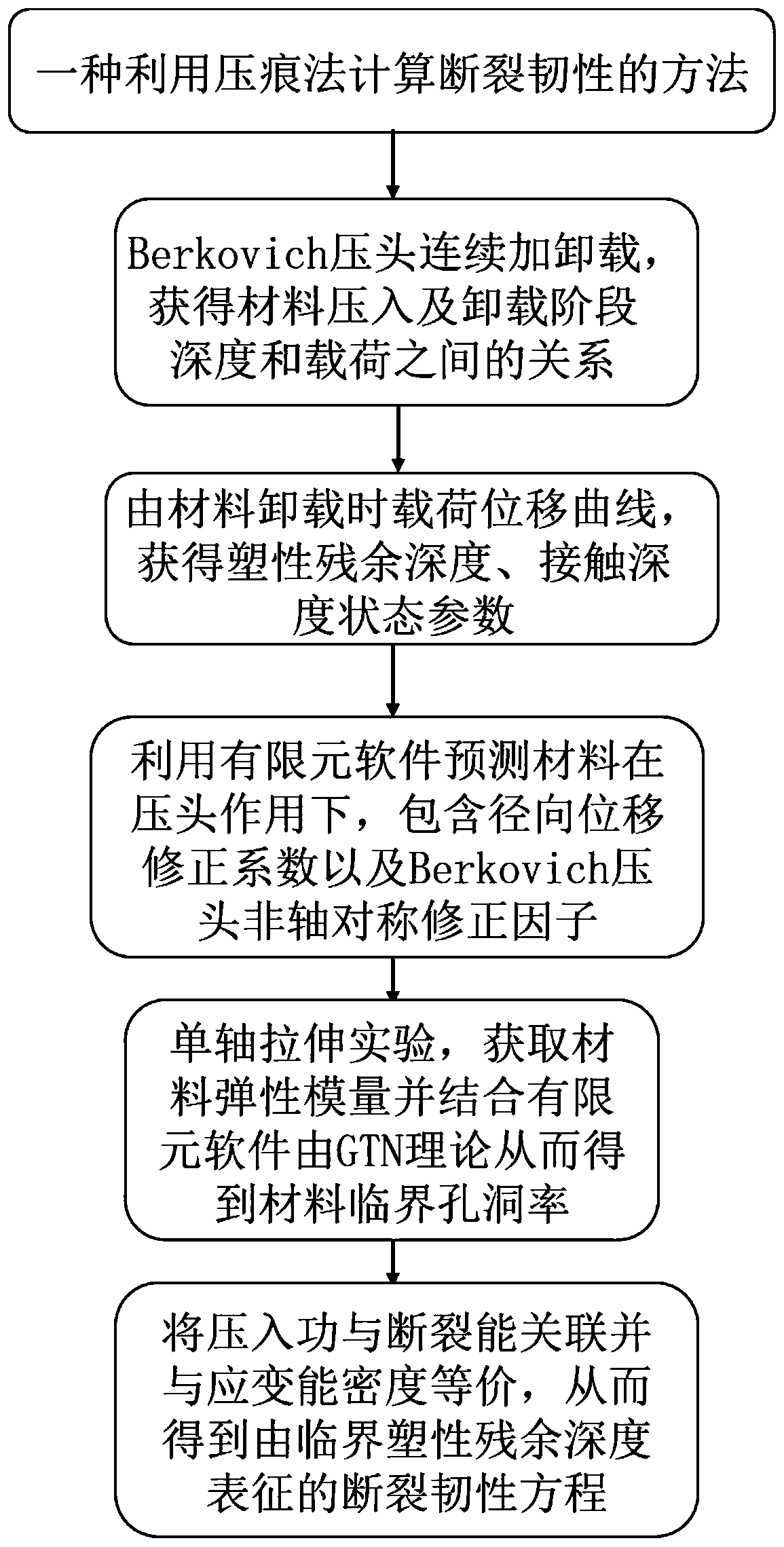

[0061] Such as Figure 1-2 Shown, a kind of indentation method calculates fracture toughness method, it is characterized in that: comprise the steps:

[0062] Step (1), based on the indentation experiment, at a constant rate, obtain the full load-displacement curve under the unloading condition of no less than 6 times;

[0063] The indentation experiment adopts the method of continuous loading and unloading of the constant Berkovich indenter. The indenter is loaded at least 6 times at a loading rate of 50mN / s, and unloaded after each loading to obtain the full load-displacement curve.

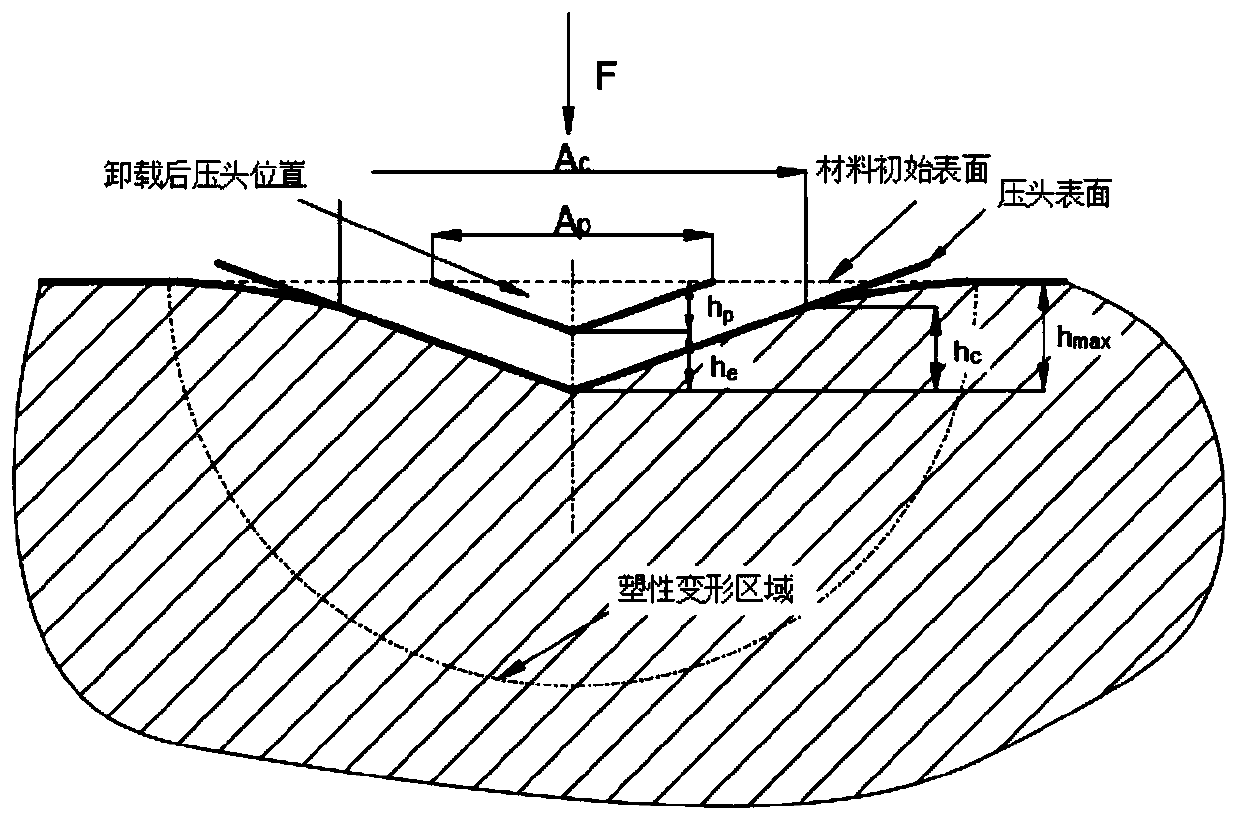

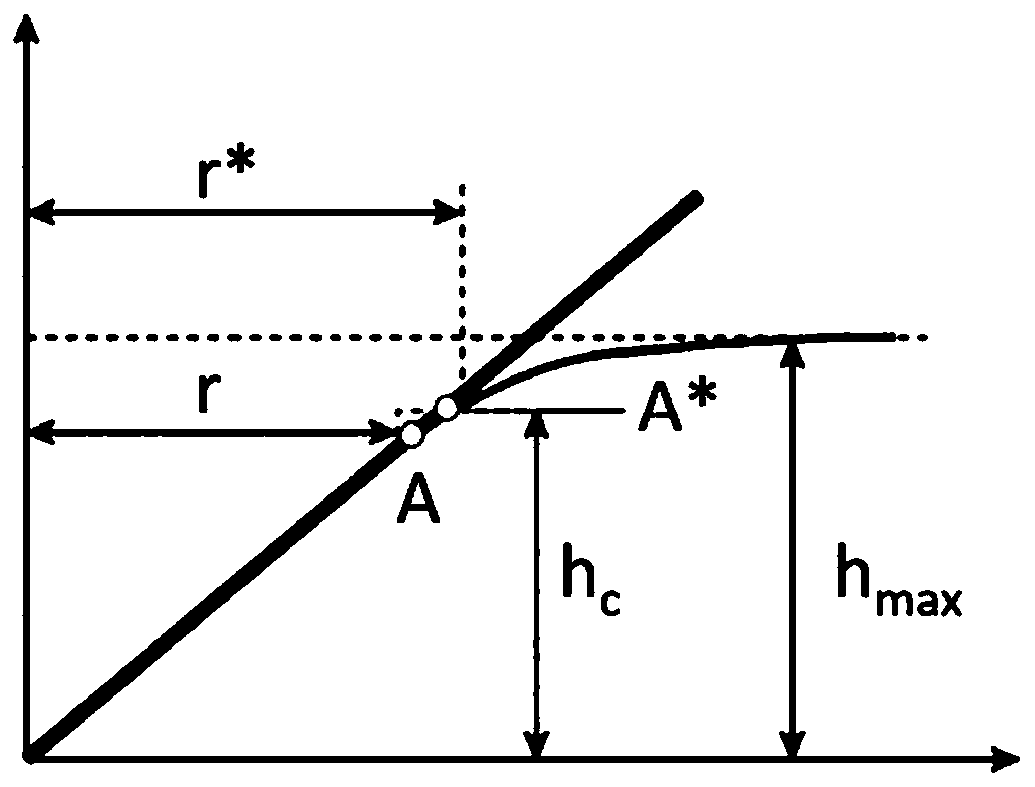

[0064] In step (2), a power function parameter fitting is performed on each unloading curve to obtain the state parameters of the plastic residual depth and contact depth, and the unloading stiffness at the unloading point of each curve is calculated, and then a straight line fitting is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com