Self-weight influence-free concrete material fracture toughness testing method

A technology of fracture toughness and testing method, applied in the field of physical measurement, can solve problems such as failure to meet test requirements, inaccurate results, and unobtainable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

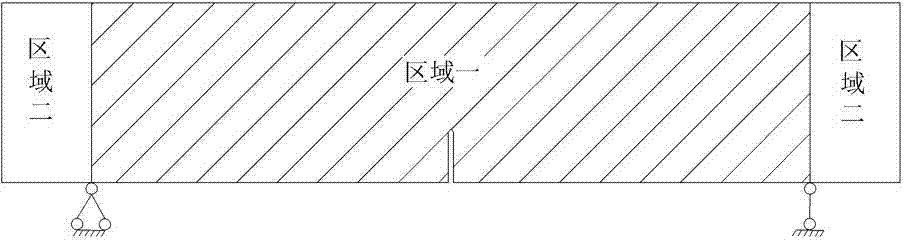

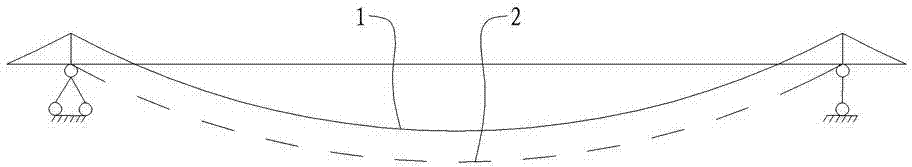

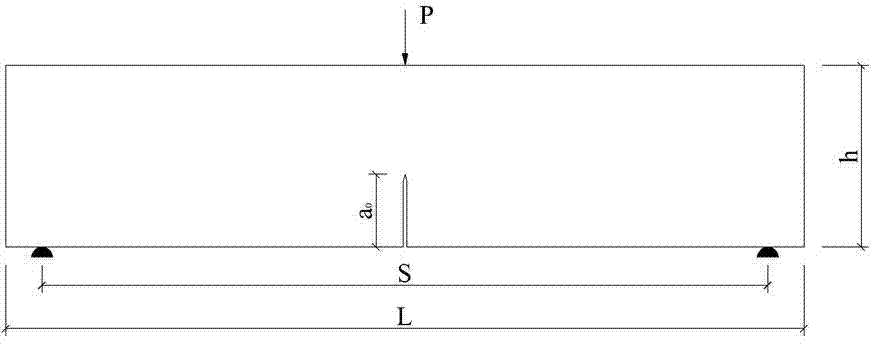

[0066] The method for testing the fracture toughness of concrete materials without the influence of self-weight of the present embodiment, such as Figure 8 , Figure 9 and Figure 10 shown, including the following steps:

[0067] 1) Erect the test beam on the two rolling bearings of the existing three-point bending beam test device, and install the load measuring device and the strain measuring device on the test beam;

[0068] The distance between two rolling bearings is 1 / 2 of the length of the test beam, and the distance from each rolling bearing to one end of its adjacent test beam is 1 / 4 of the length of the test beam;

[0069] For the existing three-point bending beam test device, refer to the test device in 6.2 of the "Hydraulic Concrete Fracture Test Regulations". The load measuring device is set on the top surface of the test beam, using a load sensor with an accuracy of not less than 1%. The strain measurement device in this embodiment is a resistance strain gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com