Method for measuring stress corrosion crack propagation rate by employing slow strain rate tensile

A technology of crack growth rate and slow strain rate, which is used in the application of stable tension/pressure to test the strength of materials and the preparation of samples for testing. Simple, distortion-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

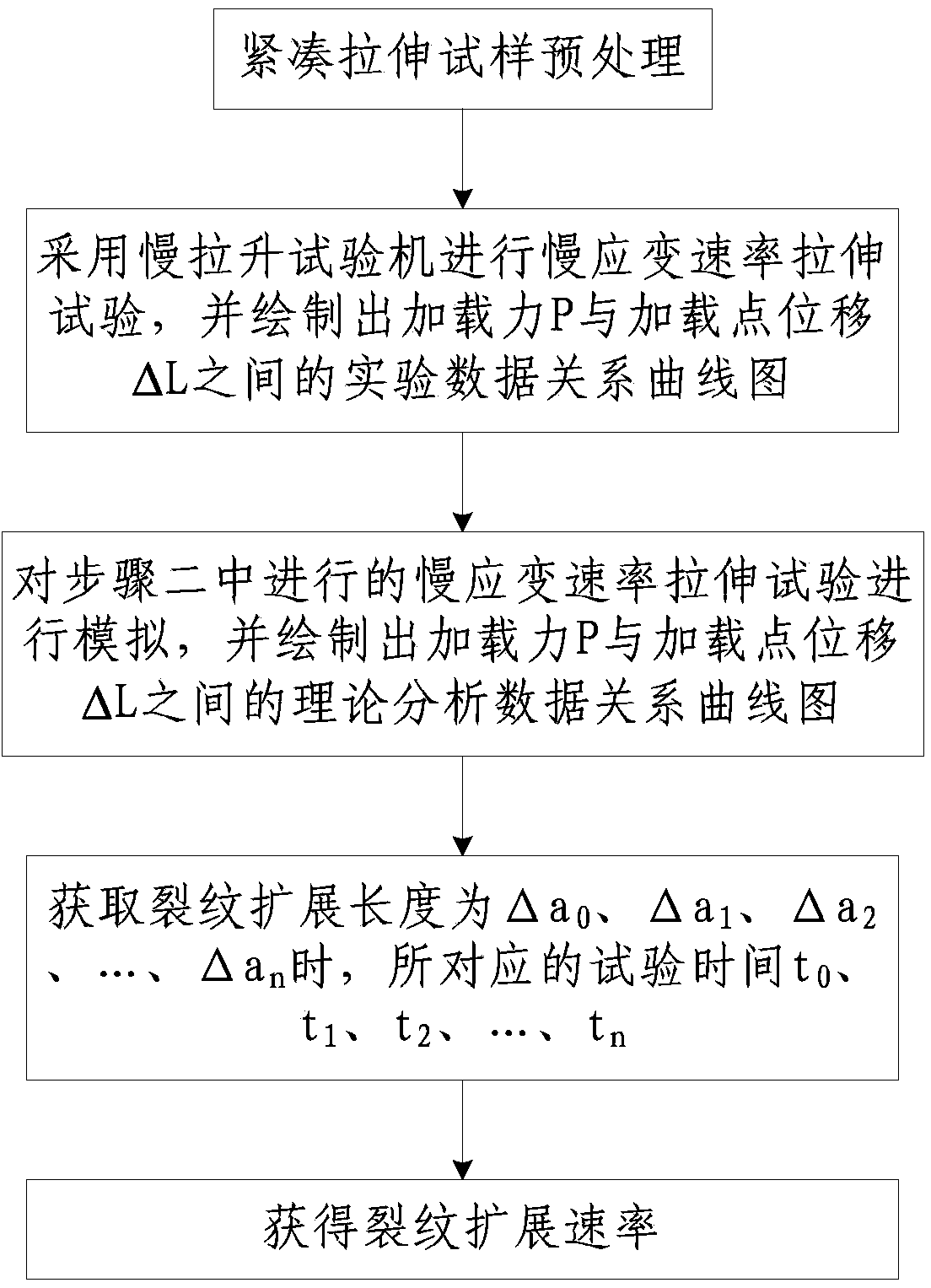

[0045] Such as figure 1 Shown, slow strain rate tensile stress corrosion crack growth rate measurement method of the present invention, comprises the following steps:

[0046] Step 1. Pretreatment of compact tensile specimens: Select a standard compact tensile specimen for slow strain rate tensile test according to ASME standards, and use wire cutting and prefabrication fatigue cracks on the standard compact tensile specimen A pre-crack crack used to initially guide crack propagation is set, and the length of the pre-crack crack is a;

[0047] In this embodiment, the value of a is 10mm.

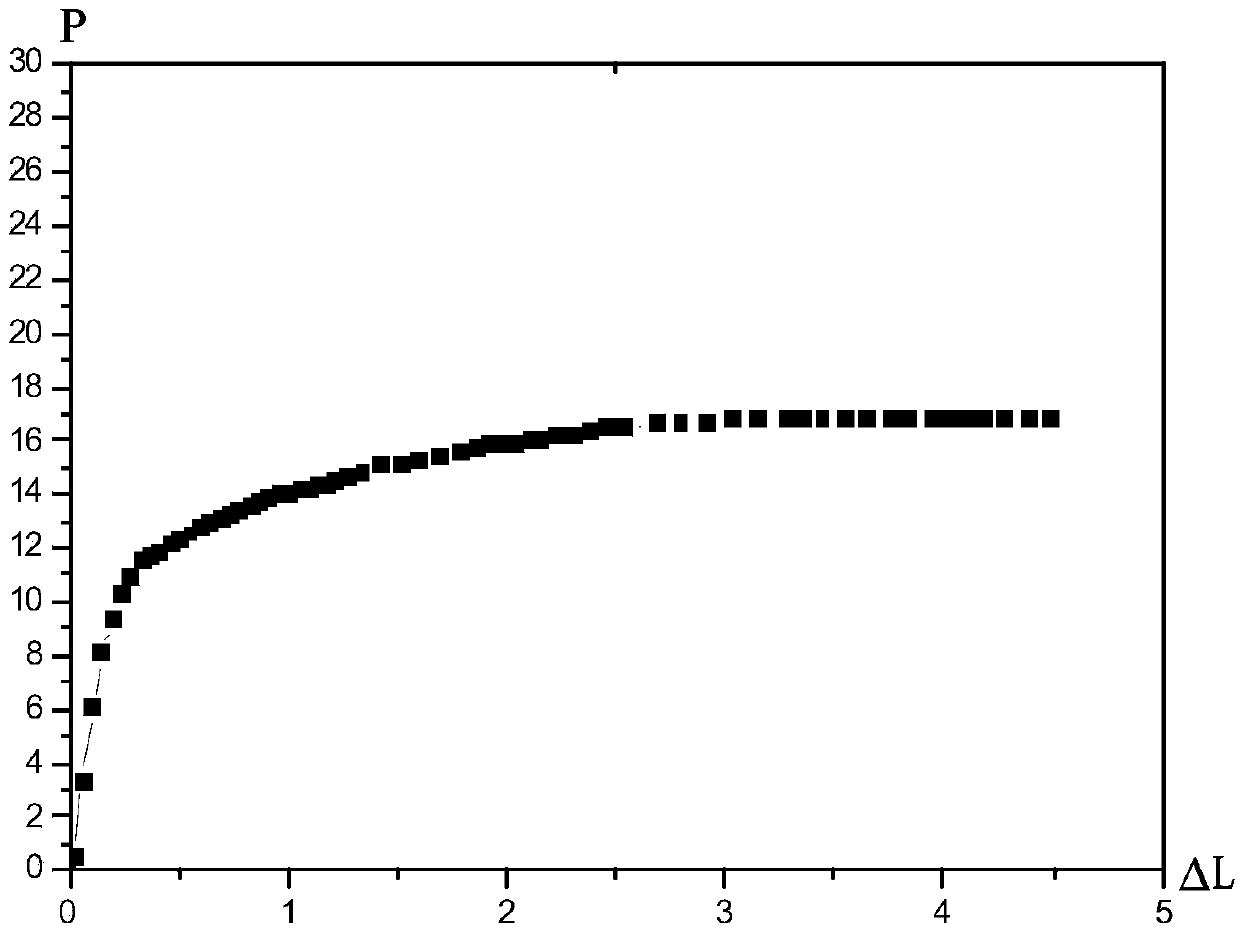

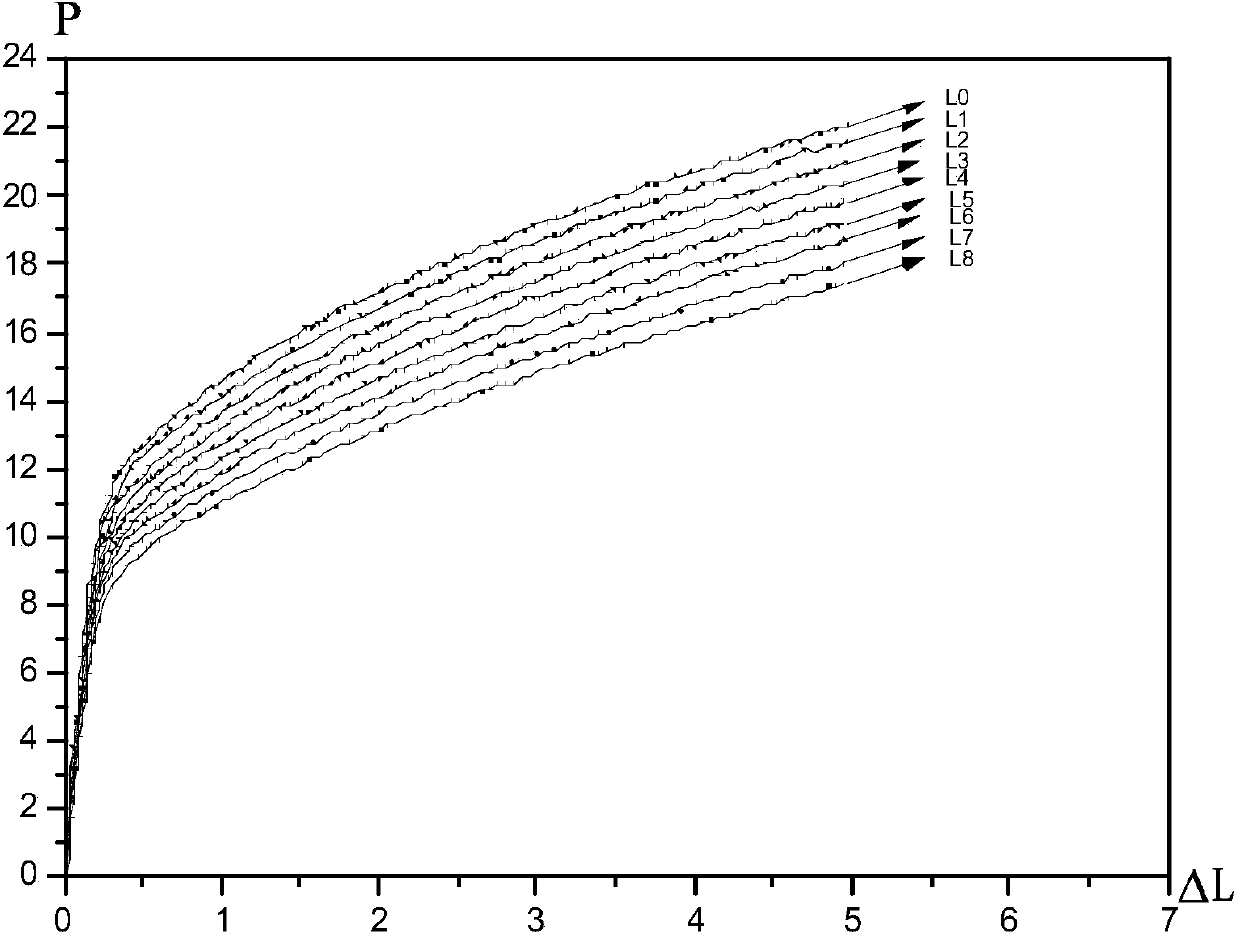

[0048] Step 2. Use a slow tension testing machine to perform a slow strain rate tensile test, and draw a curve diagram of the experimental data relationship between the loading force P and the displacement ΔL of the loading point. The specific process is as follows:

[0049] Step 201, setting the test parameters of the slow strain rate tensile test on the slow tensile testing machine, inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com