Crack opening displacement measuring device

A technology for displacement measurement and cracks, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as inability to withstand high temperatures, short-circuit of strain gauges, and failure to work normally, achieving low cost and easy operation Convenience and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

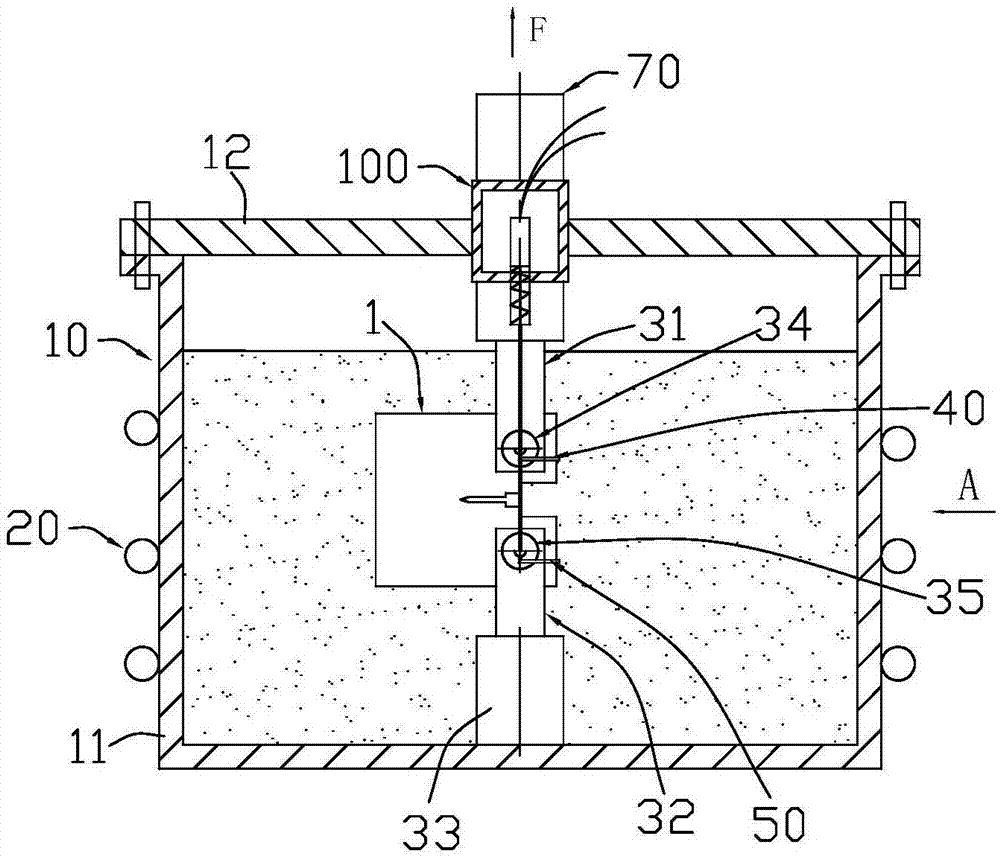

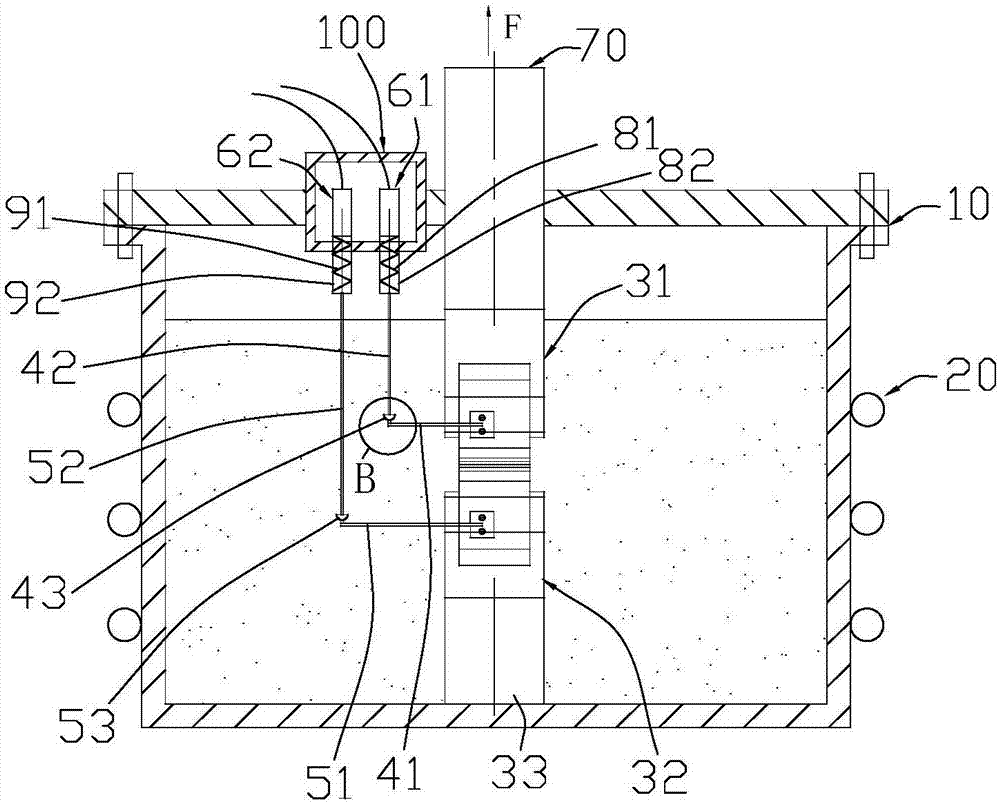

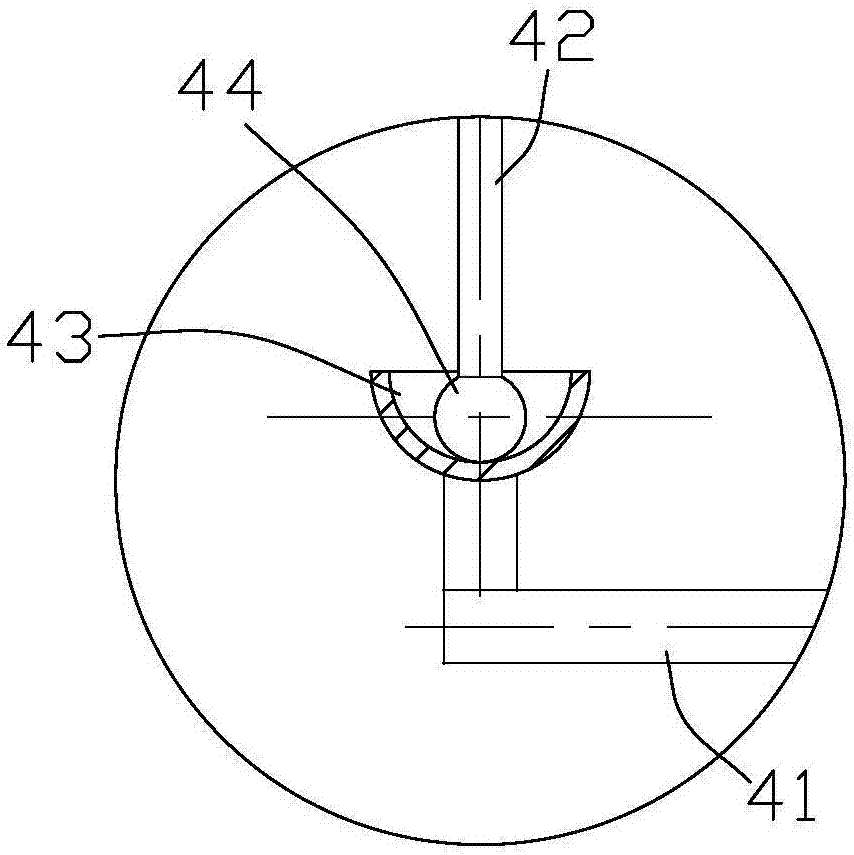

[0034] Such as figure 1 , 2 As shown, the crack opening displacement measurement device according to an embodiment of the present invention includes a closed container 10 for holding a high-temperature corrosive conductive medium, a heating unit 20 for heating the closed container 10, and a first fixing device for fixing the sample 1. 31 and the second fixing member 32, the first connecting rod assembly 40 and the second connecting rod assembly 50 that lead out the displacement of the crack opening on the sample 1, the first displacement sensor 61 and the second displacement sensor 61 that measure the crack opening drawn out sensor 62.

[0035] Wherein, the first fixing part 31 and the second fixing part 32 are relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com