Sample for measuring high temperature fracture toughness and preparation method thereof

A technology of fracture toughness and high temperature, which is applied in the field of measuring high temperature fracture toughness samples and its preparation, which can solve the problems of easy sintering of fastening screws, cumbersome preparation process, and low positioning accuracy, so as to ensure accuracy and effectiveness , The processing technology is simplified, and the effect of easy clamping on the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

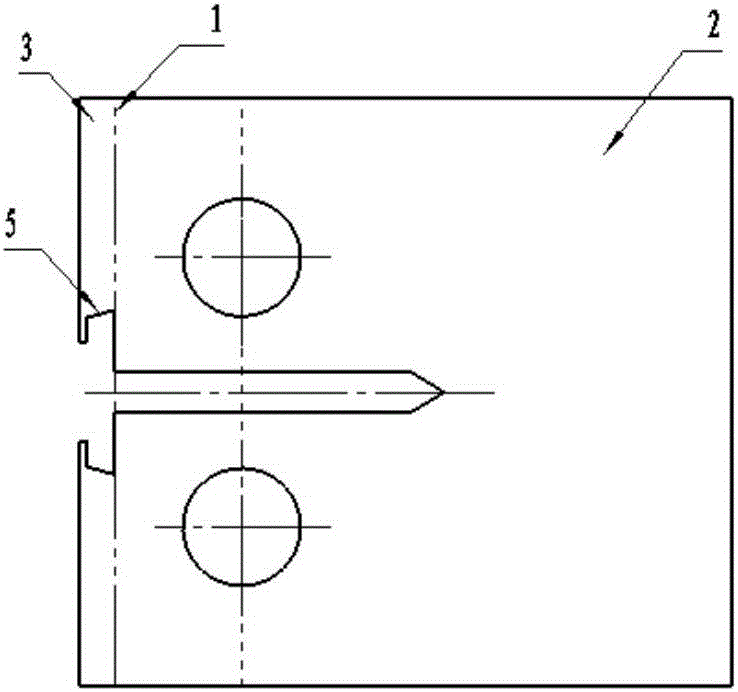

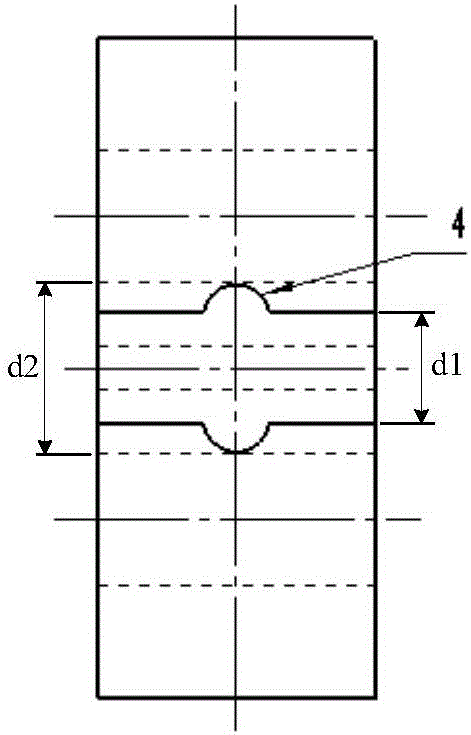

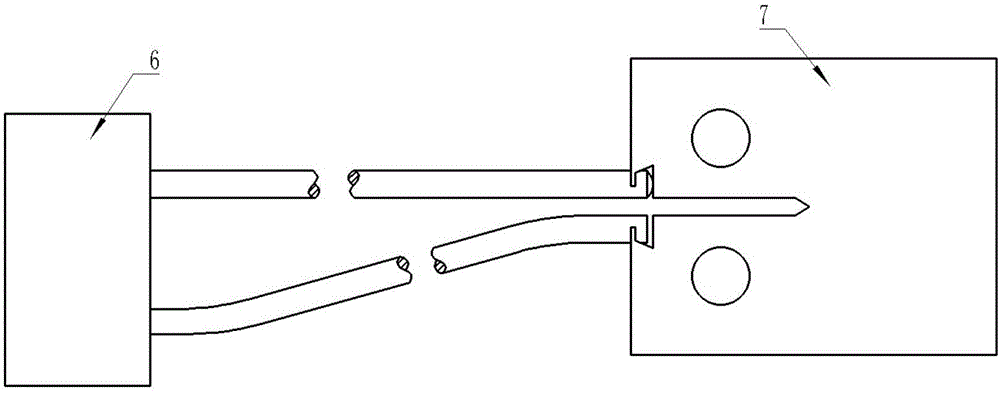

[0036] refer to figure 1 , figure 2 and image 3 , the sample 7 of the present invention includes a sample body 2, the left end of the sample body 2 is provided with a gap, the gap runs through the front and rear sides of the sample body 2, and on the upper and lower sides of the gap, the sample body 2 is respectively provided with symmetrical through hole.

[0037] The present invention takes figure 1 The left, right, up, and down directions are defined as shown, that is, the end where the notch in the sample body 2 is located is the left end, which is only for describing the present invention more clearly, rather than limiting the present invention.

[0038] An auxiliary dividing line 1 is set on the front side of the left end of the sample body 2, and on the left side of the auxiliary dividing line 1, an additional knife edge 3 is integrally provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com