Device and method for measuring crack expanding rate of compact tension specimen

A crack growth rate, compact tensile sample technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of measurement stability and accuracy reduction, achieve continuous high-precision measurement, wide application range, and reduce external signals interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

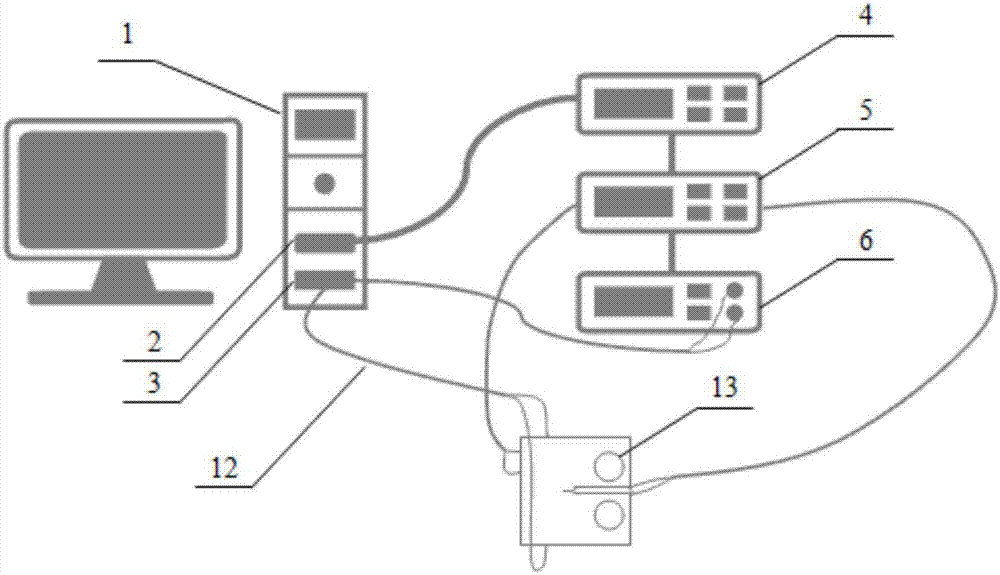

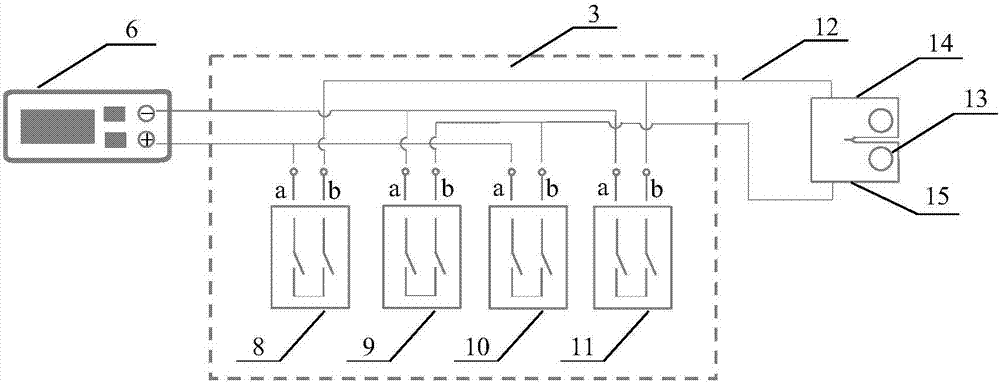

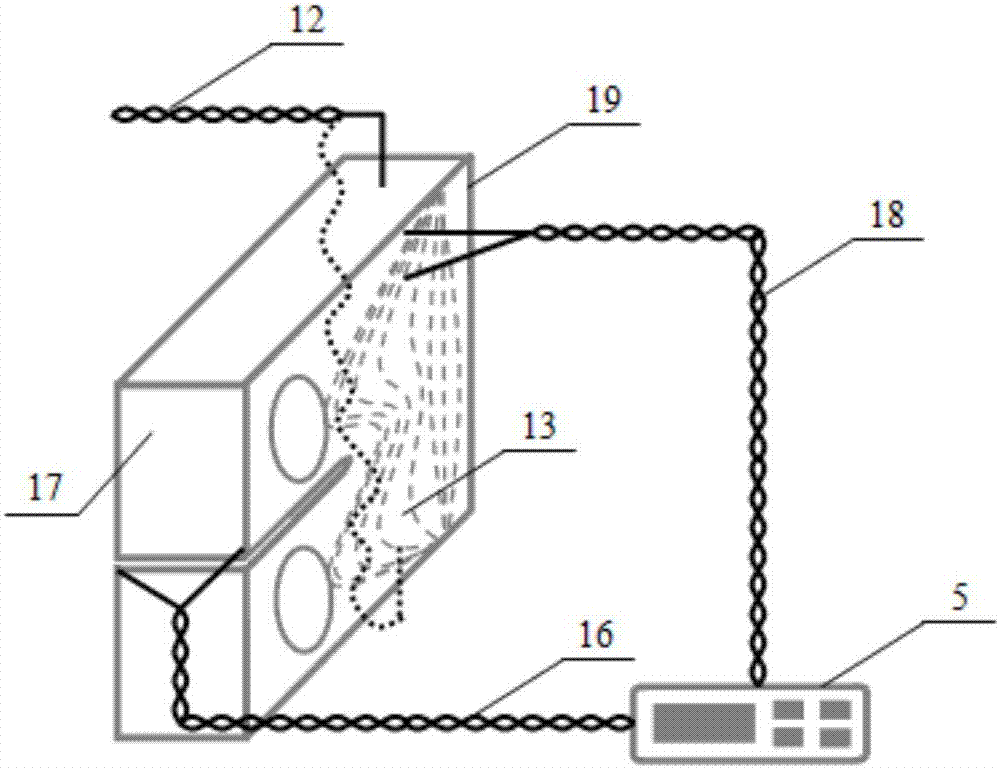

[0040] Such as Figure 1-Figure 4 , Figure 7 As shown, the DC potential drop crack growth rate measurement software of the present invention is based on the Labview environment, and the DC potential drop crack growth rate measurement software user interface is provided with: function selection, start measurement, pause measurement, setting, measurement result, measurement speed, initial length, The number of measurements, the storage path, and the crack growth curve, etc., the program flow includes: test parameter input → program start operation → system operation initialization subroutine → when the number of acquisitions is n, the system runs the continuous measurement subroutine → when the result is normal, continue to run ; When the result is abnormal, the system runs the result alarm subroutine, the system suspends the operation, and resumes operation after troubleshooting. The steps for accurate measurement of crack growth rate in compact tensile specimens are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com