Test method and test device for liquid absorption rate of macromolecular microporous diaphragm

A technology of microporous diaphragm and testing method, which is applied in the direction of material absorption and weighing, can solve the problems of poor consistency and reproducibility of test results, large artificial errors of test results, comparison of coated diaphragm and base film, etc., to achieve Representative, convincing, consistent and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Randomly select a roll of PP separator and ceramic coated separator with a thickness of 20 μm and qualified performance. Cut the separator into five groups of samples with a size of 65*1500mm, and wind them into cores with 38mm wide needles.

[0037] Take a piece of aluminum-plastic film for flexible packaging of lithium ions, cut the aluminum-plastic film into a size of 103*176mm, put the core into the aluminum-plastic film shell, and use the top-side sealing machine to seal the aluminum-plastic film on the top and side , The heat sealing temperature is about 175°C, and the samples are marked.

[0038]Put the top-side-sealed aluminum-plastic film into a vacuum oven and bake for 2 hours at a temperature of 80°C and a vacuum degree of <-0.09MPa.

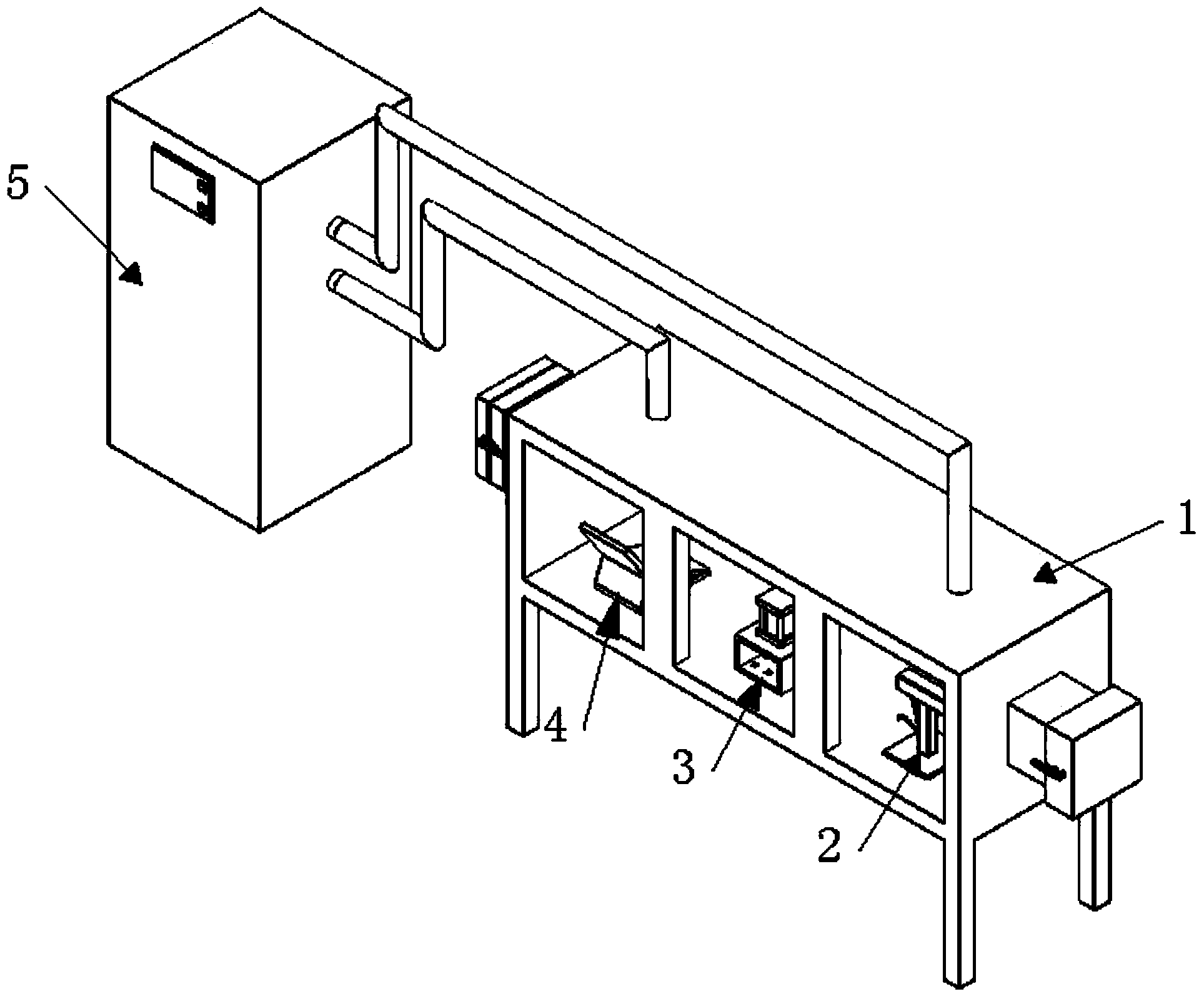

[0039] Test Set Reference figure 1 , including a glove box 1, the glove box 1 is sealed and separated into three independent spaces, and a liquid injection device 2, a vacuum static device 3 and a vacuum heat sealing device 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com