Powder coating for washing machine shell and preparation method of powder coating

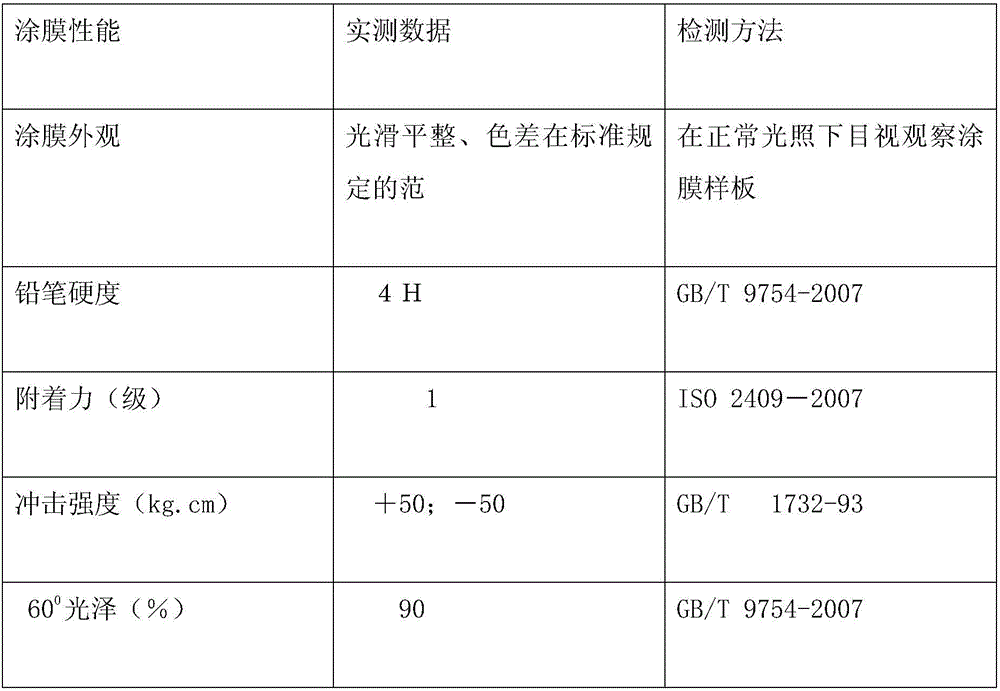

A powder coating and washing machine technology, applied in the coating field, can solve the problems of high cost and popularization, and achieve the effects of good insulation, improved corrosion resistance, and good appearance of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A powder coating for the shell of a washing machine, prepared from the following components by weight (kg): o-cresol novolac epoxy resin 85, hydantoin type epoxy resin 31, ethylenediamine 2, boron trinitride ethylamine complexed 0.6, rosin modified phenolic resin 4, glycerin 3, nano silicon dioxide 3, dimethyl silicone oil 3, vermiculite powder 7, leveling agent 2, triethanolamine 1, oleic acid 2, white oil 0.7, titanium dioxide 23, Light calcium carbonate 4, molybdenum disulfide 0.5, benzoin 0.3, modified anion powder 0.4,

[0024] Among them, the negative ion powder is composed of the following components in parts by mass: strange ice stone 14, coral fossil 9, tourmaline 13, opal 40, medical stone 3, zeolite 3, hokutolite 3, jade powder 3, diatomaceous earth 18, three Ferric oxide 3 and aluminum oxide 3 are weighed according to the proportion of each component raw material, placed in a muffle furnace, heated to 500°C, kept for 2 hours to activate, cooled to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com