Sealing method

A technology of sealing materials and tapes, which is applied in the field of sealing discontinuous parts and sealing seams, and can solve problems such as difficult appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

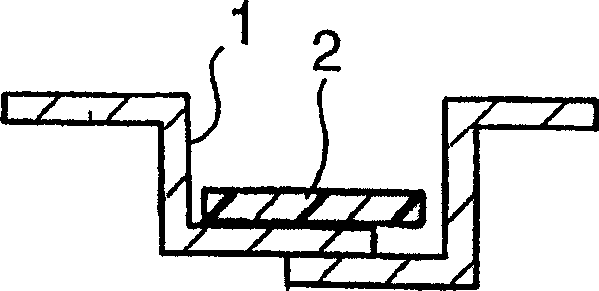

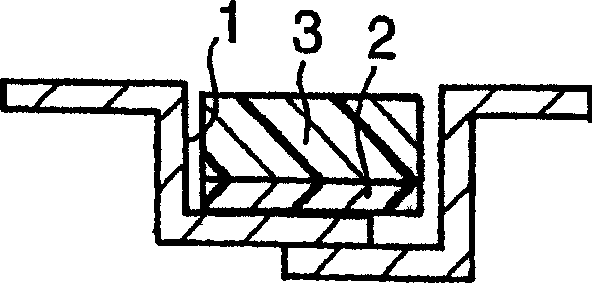

[0057] Scotch 898 tape (trade name, manufactured by Sumitomo 3M Ltd.) was pasted on the bottom of the groove of the test piece so that the tape was superimposed on the recess simulating spot welding marks, and sufficiently pressed to bond. The aforementioned seal making (fused sealant) is glued to the top surface of the strip.

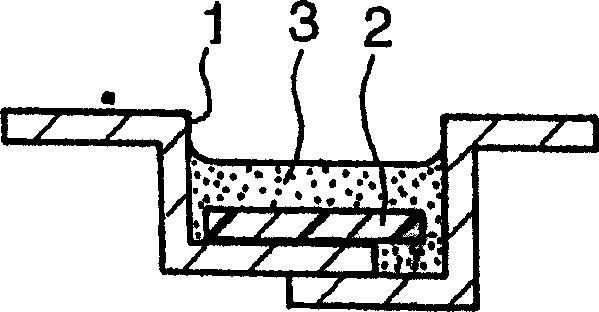

[0058] Consider the coating step of an automobile. First, the test piece was kept at 120° C. (material temperature) for 20 minutes using a pre-drying step called pre-curing the electrodeposition-coated steel sheet. Heat to melt the above molten sealant and liquefy it to cover the roof groove. Next, an automotive acrylic solid paint (crosslinked with melamine) generally called an intermediate coat paint is sprayed on the molten sealant, and cured at 140° C. (material temperature) for 30 minutes. An automotive acrylic solid paint (crosslinked with melamine) called a topcoat was then sprayed and cured at 140°C (material temperature) for 30 minutes. Bot...

Embodiment 2

[0060] Test in the same manner as in Example 1, except that Scotch 363 adhesive tape (trade name, total thickness is 190 microns, with aluminum foil and glass cloth as substrate, with silicone pressure-sensitive adhesive as coating) instead Scotch 898 tape (trade name, a fine filament tape). In addition, the substrate of the pressure-sensitive adhesive tape has a tensile elastic modulus of 350 MPa when heated at 120° C. (measured at a stretching rate of 50 mm / min, the substrate width is 24 mm, and the distance between the clamps is 100 mm).

Embodiment 3

[0062] Test in the same manner as in Example 1, except that Scotch 898 adhesive tape (trade name, a filament tape) is replaced with a pressure-sensitive adhesive tape, which is obtained by using an acrylic pressure-sensitive adhesive with a thickness of 250 microns. Prepared by coating a polyethylene terephthalate (PET) film (manufactured by Teijin Ltd.) with a thickness of 200 µm. In addition, the substrate of the pressure-sensitive adhesive tape has a tensile elastic modulus of 1000 MPa when heated at 120° C. (measured at a stretching rate of 50 mm / min, the substrate width is 24 mm, and the distance between the clamps is 100 mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com