High residual adhesive rate solvent-type paper isolation agent and preparation method thereof

A solvent-based, release agent technology, applied in the direction of no pigment coating, coating, etc., can solve the problems of high energy consumption, the inability to use silicon on both sides of paper, and residues, etc., to achieve good substrate adhesion and low Effects of release force and low silicon migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

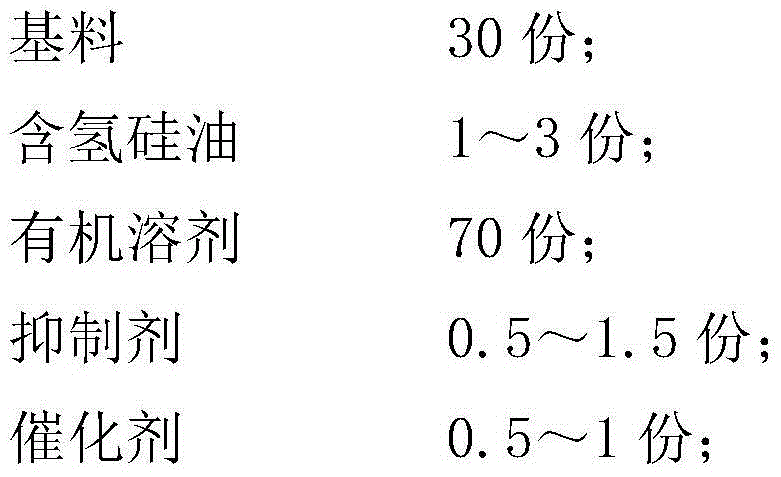

[0028] A solvent-based paper release agent with a high residual adhesion rate, its raw material formula is composed of the following components in parts by weight:

[0029]

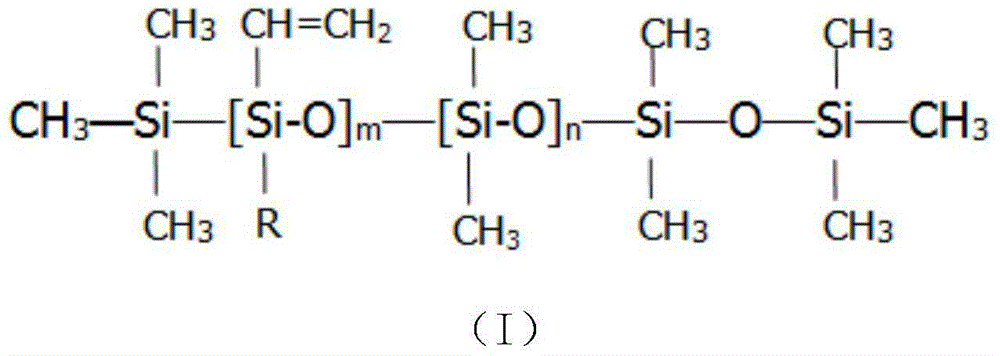

[0030] Wherein, described base material is structural formula as shown in general formula (I):

[0031]

[0032] In the above general formula (I), R is phenyl, m=220, n=7000.

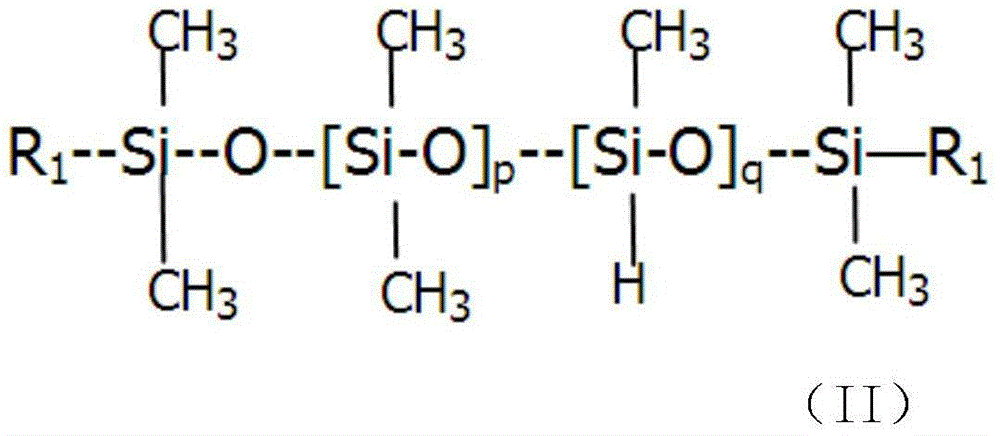

[0033] The structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0034]

[0035] In the above general formula (II), R 1 For H, p=15, q=18.

[0036] Wherein, the organic solvent is toluene;

[0037] The inhibitor is tetramethyldivinyldisiloxane;

[0038] The catalyst is a platinum-siloxane complex catalyst, and the mass fraction of platinum is 0.65% to 0.73%;

[0039] The preparation method of the solvent-based paper release agent of above-mentioned high residual adhesion rate, comprises the steps:

[0040] (1) first mix the base material with the organic solvent, then add the ...

Embodiment 2

[0045] A solvent-based paper release agent with a high residual adhesion rate, its raw material formula is composed of the following components in parts by weight:

[0046]

[0047] Wherein, described base material is structural formula as shown in general formula (I):

[0048]

[0049]

[0050] In the above general formula (I), R is phenyl, m=220, n=7000.

[0051] Preferably, the structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0052]

[0053] In the above general formula (II), R 1 for CH 3 , p=15, q=20.

[0054] Wherein, the organic solvent is xylene;

[0055] The inhibitor is tetramethyltetravinylcyclotetrasiloxane;

[0056] The catalyst is a platinum-siloxane complex catalyst, and the mass fraction of platinum is 0.65% to 0.73%;

[0057] The preparation method of the solvent-based paper release agent of above-mentioned high residual adhesion rate, comprises the steps:

[0058] (1) first mix the base material ...

Embodiment 3

[0063] A solvent-based paper release agent with a high residual adhesion rate, its raw material formula is composed of the following components in parts by weight:

[0064]

[0065] Wherein, described base material is structural formula as shown in general formula (I):

[0066]

[0067] In the above general formula (I), R is phenyl, m=220, n=7000.

[0068] Preferably, the structural formula of the hydrogen-containing silicone oil is shown in general formula (II):

[0069]

[0070] In the above general formula (II), R 1 for CH 3 , p=30, q=20.

[0071] Wherein, the organic solvent is 120# gasoline;

[0072] The inhibitor is tetramethyltetravinylcyclotetrasiloxane;

[0073]The catalyst is a platinum-siloxane complex catalyst, and the mass fraction of platinum is 0.65% to 0.73%;

[0074] The preparation method of the solvent-based paper release agent of above-mentioned high residual adhesion rate, comprises the steps:

[0075] (1) first mix the base material with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com