Silicone release agent composition, release sheet and release film

A composition and release agent technology, applied in the direction of adhesives, pressure-sensitive films/sheets, synthetic resin layered products, etc., can solve problems such as high material prices, and achieve the effects of cheap manufacturing, excellent peelability, and excellent light peeling force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

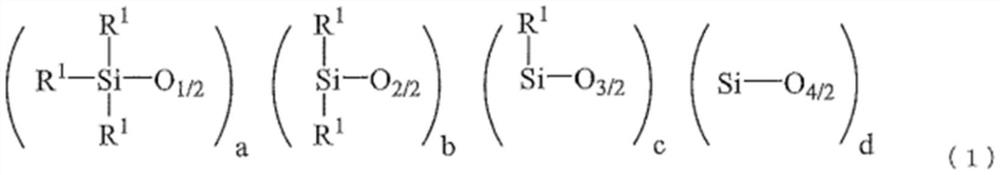

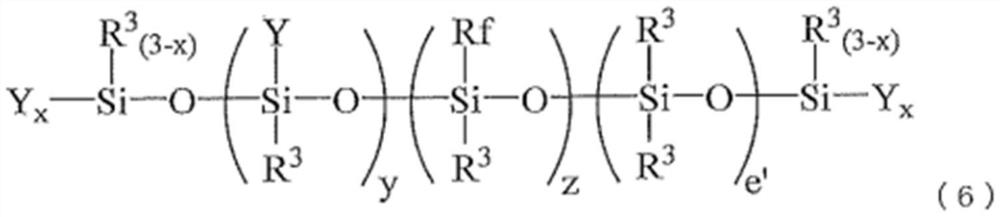

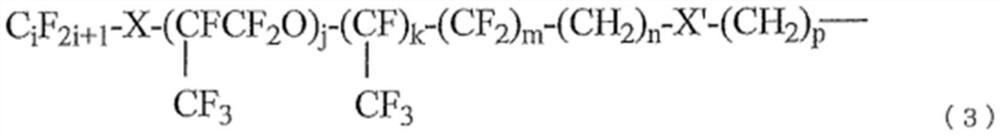

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0298] [Example 1 to Example 3, Comparative Example 1]

[0299] Coat 1.0 g / m in terms of solid content on a PET film with a thickness of 38 μm using a bar coater 2 The obtained silicone release agent composition was heated and cured in a hot air dryer at 120° C. for 40 seconds to form a release layer to prepare a release film.

Embodiment 4~ Embodiment 8、 comparative example 2~ comparative example 9

[0301] Coat 0.3 g / m in terms of solid content on a PET film with a thickness of 38 μm using a bar coater 2 The obtained silicone release agent composition was heated and cured in a hot air dryer at 140° C. for 30 seconds to form a release layer to prepare a release film.

[0302]

[0303] (adhesive tape A)

[0304] The silicone adhesive composition used to make the adhesive tape A was prepared as follows.

[0305] (G1) 36 parts by mass of dimethyl polysiloxane represented by the following formula,

[0306] [chem 48]

[0307]

[0308] (H1) has Me 3 SiO 0.5 Unit and SiO 2 Units of polysiloxane (Me 3 SiO 0.5 Unit / SiO 2 Unit (molar ratio) = 0.85, weight average molecular weight 4,000) of 60% by mass toluene solution 106.7 parts by mass,

[0309] (1) 0.32 parts by mass of methylhydrogenpolysiloxane represented by the following formula,

[0310] [chem 49]

[0311]

[0312] 0.25 parts by mass of 1-ethynylcyclohexanol was mixed and diluted with toluene to obtain a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com