A kind of hydrocarbon-based modified mdq type silicone resin and its preparation method and application

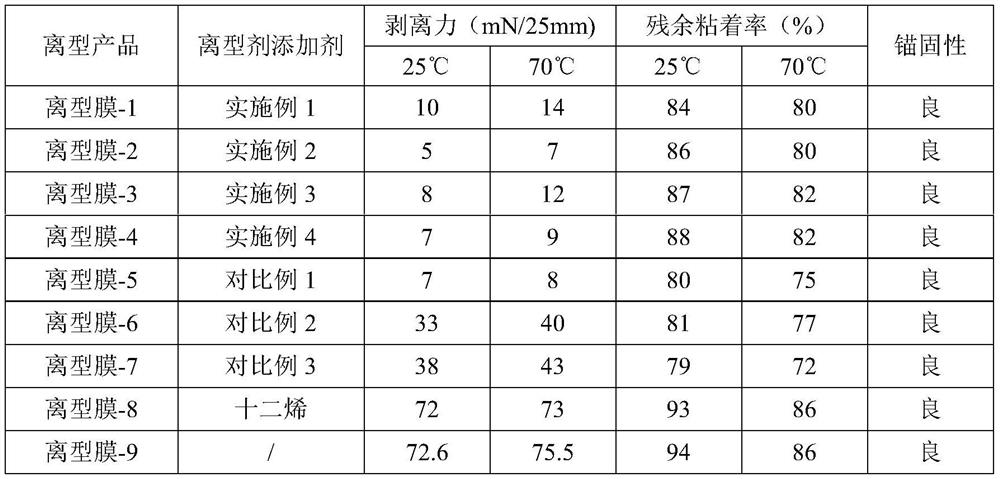

A silicone resin and modified technology, applied in the direction of coating, etc., can solve the problems of not meeting high adhesion performance and low peeling performance at the same time, and achieve the effect of small peeling force and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a hydrocarbon-modified MDQ type silicone resin, which is prepared according to the following method:

[0038] In the reaction equipment equipped with a stirrer, a thermometer, and a reflux condenser, add 670 parts by mass of tetramethyldihydrodisiloxane (10 mol of silicon hydrogen), 1344 parts by mass of n-octene (12 mol of C=C double bonds), Karstedt 2.0 parts by mass of the catalyst (with a Pt content of 10 ppm), reflux reaction at 65-70° C. for 2 hours, and then evacuated at 160° C. / 10 mmHg for 2 hours to obtain dioctyltetramethyldisiloxane.

[0039] Dioctyltetramethyldisiloxane (2mol) of 716 parts by mass and 208 parts of ethyl orthosilicate (1

[0040] mol), 240 parts by mass (4mol) of acetic acid, reflux reaction at 70-75°C for 4 hours, and then vacuumize at 160°C / 10mmHg for 2 hours to obtain octyl-modified polysiloxane with Q-type structure.

[0041] React 776 parts by mass of octyl-modified polysiloxane (1mol) with Q-type structure, 533...

Embodiment 2

[0044] This embodiment provides a hydrocarbon-modified MDQ type silicone resin, which is prepared according to the following method:

[0045] In the reaction equipment equipped with a stirrer, a thermometer, and a reflux condenser, add 670 parts by mass of tetramethyldihydrodisiloxane (10 mol of silicon hydrogen), 2016 parts by mass of dodecene (12 mol of C=C double bond), Karstedt Catalyst 2.7 parts by mass (Pt content 10ppm), reflux reaction at 65-70°C for 2 hours, and then evacuated at 160°C / 10mmHg for 2 hours to obtain dodecyltetramethyldisiloxane.

[0046]940 mass parts of dodecyltetramethyldisiloxane (2mol) and 208 parts (1mol) of ethyl orthosilicate, 240 mass parts (4mol) of acetic acid, reflux reaction at 70-75 ° C for 4 hours, and then Vacuum at 160° C. / 10 mmHg for 2 hours to obtain dodecyl-modified polysiloxane with Q-type structure.

[0047] 1000 parts by mass of dodecyl-modified polysiloxane (1mol) with Q-type structure and 11864 parts by mass of octamethylcyclote...

Embodiment 3

[0050] This embodiment provides a hydrocarbon-modified MDQ type silicone resin, which is prepared according to the following method:

[0051] In the reaction equipment equipped with a stirrer, a thermometer, and a reflux condenser, add 670 parts by mass of tetramethyldihydrodisiloxane (10 mol of silicon hydrogen), 2692.8 parts by mass of hexadecene (12 mol of C=C double bonds), Karstedt Catalyst 3.4 parts by mass (Pt content 10ppm), reflux reaction at 65-70°C for 2 hours, then evacuated at 160°C / 10mmHg for 2 hours to obtain hexadecyltetramethyldisiloxane.

[0052] 1165.6 parts by mass of hexadecyltetramethyldisiloxane (2mol) and 208 parts (1mol) of ethyl orthosilicate, 240 parts by mass (4mol) of acetic acid, were refluxed at 70-75°C for 4 hours, and then Vacuum at 160° C. / 10 mmHg for 2 hours to obtain a hexadecyl-modified polysiloxane with a Q-type structure.

[0053] 1224 parts by mass of hexadecyl-modified polysiloxane (1mol) of Q-type structure and 5392 parts by mass of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com