A matte release film

A release film and matte technology, applied in the direction of coating, etc., can solve the problems of unfavorable use in the electronics industry, achieve the effects of saving coating time and production cycle, improving wear resistance, and high residual adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

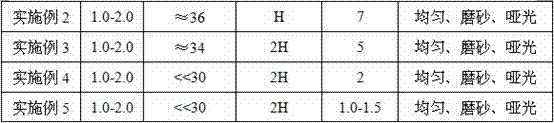

Examples

preparation example Construction

[0070] The present invention provides the preparation method of the thermosetting coating of above-mentioned release film, it comprises the following steps:

[0071] Mix part of organic mixed solvent 1 with organic fluorine resin, stir at room temperature, add melamine resin, aldehyde and ketone resin, acrylic resin, etc. in turn while stirring, stir evenly, and slowly add matting agent and dispersant at the same time, you can get Resin mixture paste. The focus of preparing the main ingredient is to control the speed of mixing and resin addition to avoid foaming or gelling. The obtained resin mixture slurry is uniform and thick without gelling, foaming or agglomeration.

[0072] Put the above resin mixture slurry into the sand mill for sand grinding several times, control the sand grinding speed at 2-4L / min, add antistatic agent during the grinding process, control the overall temperature of the sand mill below 40°C, select the corresponding The filter core is filtered to obt...

Embodiment 1

[0079] Fluorine resin HLR-1 3.0kg

[0080] Acrylic 170B 3.0kg

[0081] Aldehyde Resin KR-120 1.0kg

[0082] Curing agent amino resin A03 2.0kg

[0083] Curing agent blocked isocyanate 1358A 1.0kg

[0084] Auxiliary p-toluenesulfonic acid PTSA 0.2kg

[0085] Auxiliary antistatic agent SN 0.3kg

[0086] Auxiliary Dispersant DISPERBYK-110 0.3kg

[0087] Mixed solvent 1 Toluene: Butanone: Cyclohexanone=4:6:1 1.0kg

[0088] Mixed solvent 2 isopropanol: methyl ethyl ketone = 4:1 1kg

[0089] Matting agent Silica (particle size 1-3μm) 1.5kg

[0090] Matting agent Titanium dioxide (particle size 1.0-3.0μm) 1.5kg;

[0091] in:

[0092] Fluorine resin HLR-1 has a hydroxyl value of 50, an acid value of 1-5, and a number average molecular weight of 6000-25000

[0093] Acrylic resin 170B has a hydroxyl value of 120mgKOH / g and an acid value of 15 mgKOH / g

[0094] The coating solution was coated on a 125 micron thick PET substrate. The above release layer slurry is coated by an ani...

Embodiment 2

[0097] Fluorine resin HLR-1 4.0kg

[0098] Acrylic 170E 3.0kg

[0099] Aldehyde Resin A81 2.0kg

[0100] Curing agent amino resin A03 2.0kg

[0101] Curing agent isocyanate 1358A 0.5kg

[0102] Auxiliary PTSA 0.2kg

[0103] Auxiliary antistatic agent SN 0.2kg

[0104] Auxiliary Dispersant DISPERBYK-110 0.2kg

[0105] Mixed solvent 1 Toluene: Butanone: Cyclohexanone=4:6:1 11.0kg

[0106] Mixed solvent 2 isopropanol: methyl ethyl ketone = 4:1 1.0kg

[0107] Silica (particle size 2-4μm) 1.0kg

[0108] Titanium dioxide (particle size 1.0-3.0μm) 1.5kg;

[0109] in:

[0110] Fluorine resin HLR-1 has a hydroxyl value of 50, an acid value of 1-5, and a number average molecular weight of 6000-25000

[0111] The hydroxyl value of acrylic resin 170E is 86mgKOH / g, and the acid value can be 9-15 mgKOH / g

[0112] On the PET substrate with a thickness of 50 μm, the above-mentioned release layer slurry is coated by three rolls, and fully dried and solidified to obtain a release pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com