Water-based floor marking coating and preparation method thereof

A floor, water-based technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of blurred markings, poor flexibility, poor impact resistance, etc., and achieve excellent solvent resistance and aging resistance. The effect of improving substrate adhesion and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

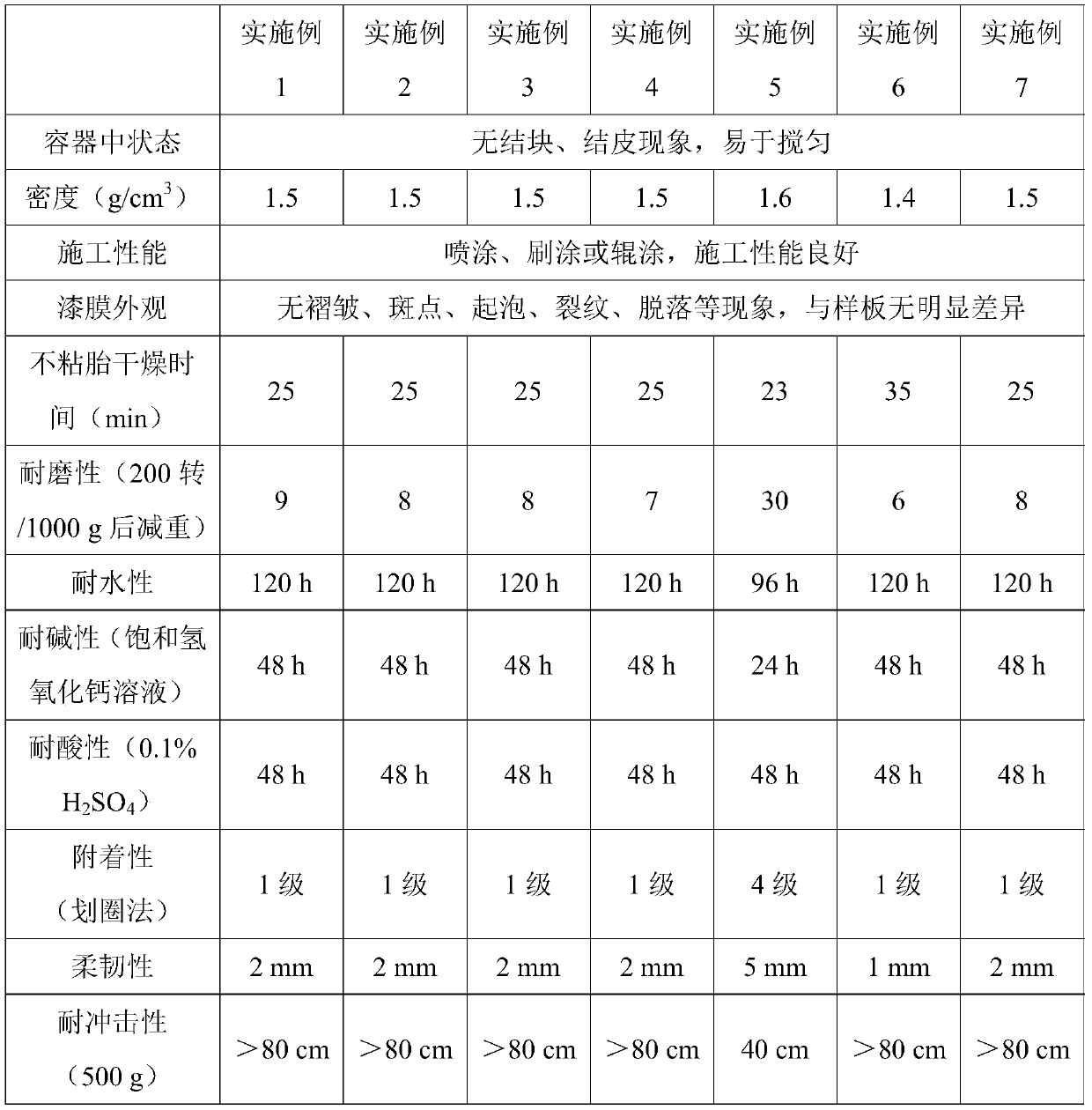

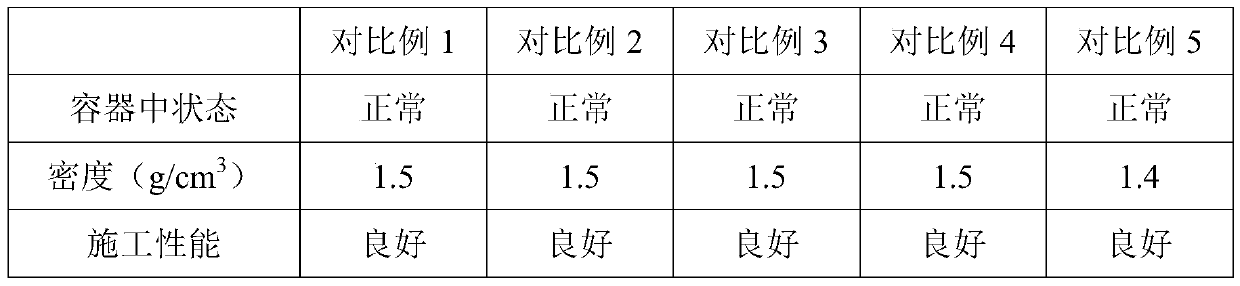

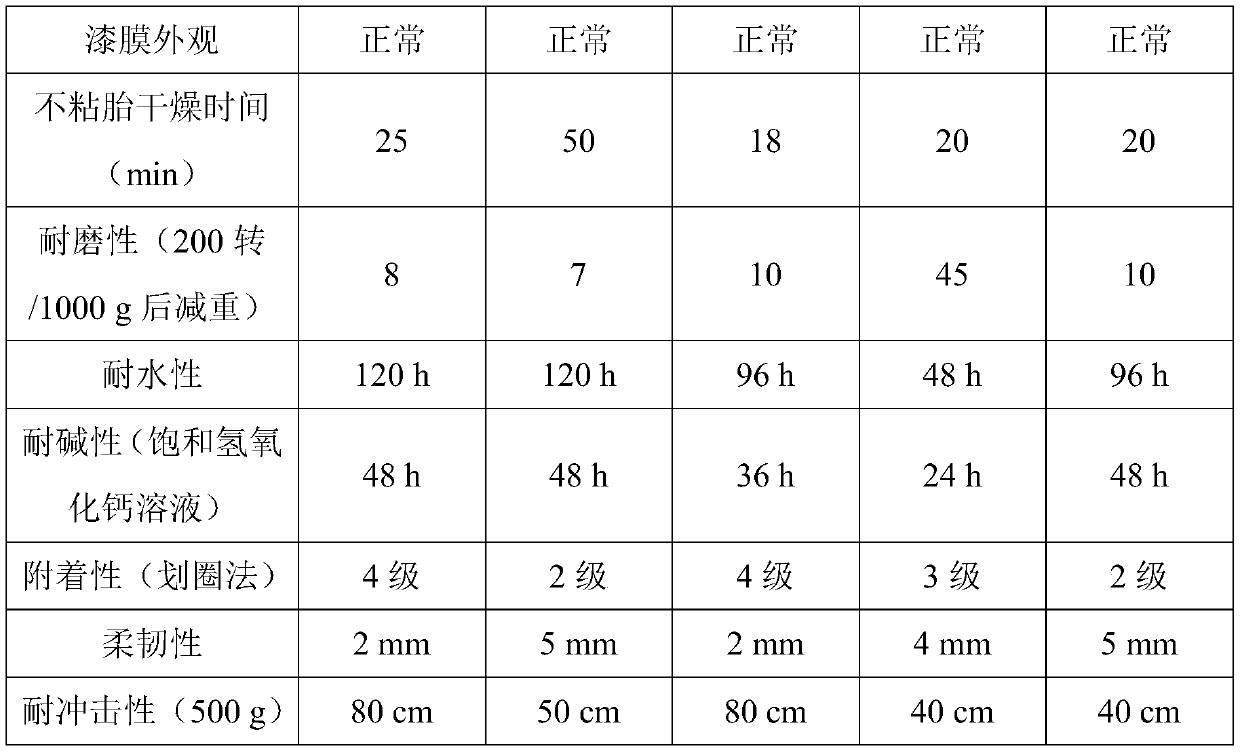

Examples

Embodiment 1

[0083] The present embodiment provides a kind of water-based floor paint, the components are as follows:

[0084] Component A: 39 parts by weight of water-based polyurethane resin, 19 parts by weight of titanium dioxide, 21 parts by weight of heavy calcium carbonate, 0.1 part by weight of adhesion promoter, 0.4 part by weight of bentonite, 1.0 part by weight of dispersant, and 0.2 part by weight of wetting agent , 0.3 parts by weight of defoamer, 0.1 parts by weight of pH regulator, 0.1 parts by weight of preservative, 1.3 parts by weight of thickener and 17.5 parts by weight of water;

[0085] Component B: 17 parts by weight of isocyanate curing agent, and 1.7 parts by weight of propylene glycol diacetate.

[0086] The preparation method is as follows:

[0087] (1) Add water into the tank according to the formula amount of component A, turn on the disperser, slowly add dispersant, wetting agent, defoamer and pH regulator in sequence at a speed of 550r / min, and stir after add...

Embodiment 2

[0091] The present embodiment provides a kind of water-based floor paint, the components are as follows:

[0092] Component A: 41 parts by weight of water-based polyurethane resin, 20 parts by weight of titanium dioxide, 20 parts by weight of ground calcium carbonate, 0.1 parts by weight of adhesion promoter, 0.5 parts by weight of bentonite, 1.0 parts by weight of dispersant, and 0.2 parts by weight of wetting agent , 0.3 parts by weight of defoamer, 0.1 parts by weight of pH regulator, 0.1 parts by weight of preservative, 1.2 parts by weight of thickener and 15.5 parts by weight of water;

[0093] Component B: 18 parts by weight of isocyanate curing agent, 1.8 parts by weight of propylene glycol diacetate.

[0094] The preparation method is as follows:

[0095] (1) Add water into the tank according to the formula amount of component A, turn on the disperser, slowly add dispersant, wetting agent, defoamer and pH regulator at a speed of 500r / min, and stir after adding 3min; ...

Embodiment 3

[0099] The present embodiment provides a kind of water-based floor paint, the components are as follows:

[0100] Component A: 43 parts by weight of water-based polyurethane resin, 21 parts by weight of titanium dioxide, 19 parts by weight of ground calcium carbonate, 0.1 part by weight of adhesion promoter, 0.6 parts by weight of bentonite, 1.0 parts by weight of dispersant, and 0.2 parts by weight of wetting agent , 0.3 parts by weight of defoamer, 0.1 parts by weight of pH regulator, 0.1 parts by weight of preservative, 1.1 parts by weight of thickener and 13.5 parts by weight of water;

[0101] Component B: 19 parts by weight of isocyanate curing agent, and 1.9 parts by weight of propylene glycol diacetate.

[0102] The preparation method is as follows:

[0103] (1) Add water into the tank according to the formula amount of component A, turn on the disperser, slowly add dispersant, wetting agent, defoamer and pH regulator in sequence at a speed of 600r / min, and stir after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com