Method for forming multilayered coating film

A multi-layer coating and coating technology, applied in chemical instruments and methods, devices for coating liquids on surfaces, coatings, etc., can solve problems such as no description, and achieve the effect of high saturation and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

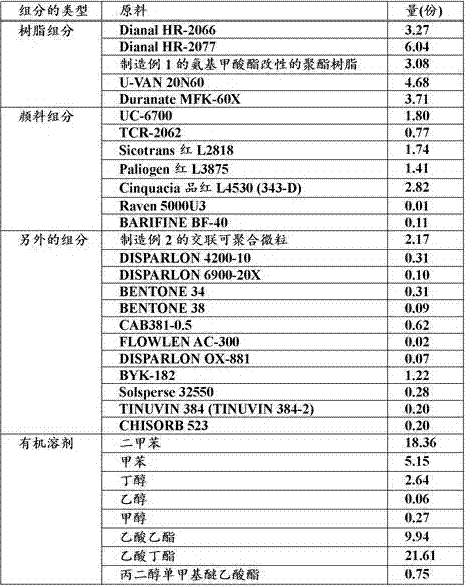

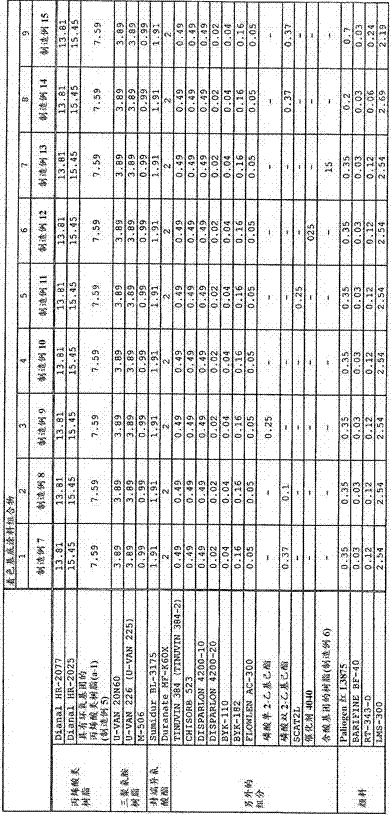

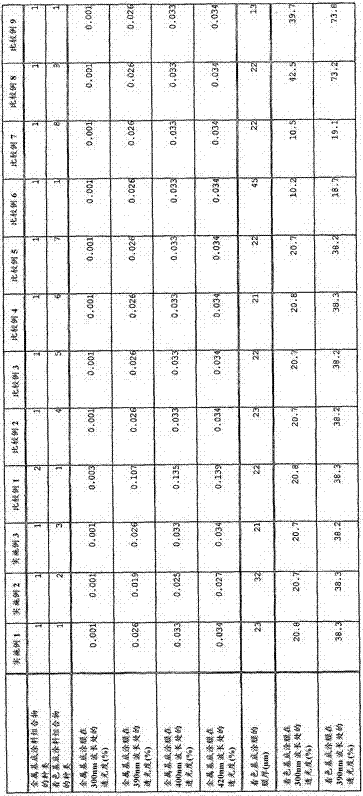

Examples

preparation example Construction

[0075] In the preparation of the hydroxyl-containing polyester resins, in addition to the acid components and polyols mentioned above, further reactive components can also be used. Examples of additional reactive components include monocarboxylic acids, hydroxycarboxylic acids, certain lactones, drying oils, semi-drying oils, fatty acids thereof, and the like. More specifically, examples thereof include monoepoxide compounds such as Cardura E (available from Shell Chemicals Japan Ltd.) and certain lactones. A certain lactone mentioned above is a component that can undergo a ring-opening addition reaction with a certain polyester between a polycarboxylic acid and a polyhydric alcohol to form a grafted chain, examples of which include β-propiolactone (propiolacron ), dimethylpropiolactone, butyl lactone, γ-valerolactone, ε-caprolactone, γ-caprolactone, γ-octyl lactone, crotolactone, δ-valerolactone Esters, δ-caprolactone, etc., among which ε-caprolactone is most preferable.

...

Embodiment

[0189] The present invention will be described in more detail with reference to the following examples, but the present invention is not limited thereto. In the examples, "part" and "%" refer to those by mass unless otherwise specified.

manufacture example 1

[0191] Production Example 1: Production of urethane-modified polyester resin

[0192] Into a 2 L reaction vessel equipped with nitrogen inlet tube, stirrer, temperature controller and condenser with dropping funnel and decanter, add 440 parts of isophthalic acid, 20 parts of hexahydrophthalic acid, 40 parts Azelaic acid, 300 parts trimethylolpropane and 200 parts neopentyl glycol. When the reaction vessel was heated and the dissolved raw materials became stirrable, 0.2 parts of dibutyltin oxide was added thereto, and the temperature of the reaction vessel was gradually raised from 180°C to 220°C over 3 hours with stirring. The resulting condensate is distilled outside the system. After the temperature reached 220° C., the temperature was maintained for 1 hour, and then 20 parts of xylene was gradually added to the contents of the reaction vessel to conduct a condensation reaction in the presence of a solvent. After the acid value of the resin reached 10 mgKOH / g, the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com