Method for forming multilayer coating film

A multi-layer coating film and coating film technology, which is applied to the surface coating liquid device, coating, electrolytic coating, etc., can solve the problems of mutual interference of coating film layers, deterioration of multi-layer coating film appearance, etc., to prevent flow Hanging, the effect of excellent coating appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

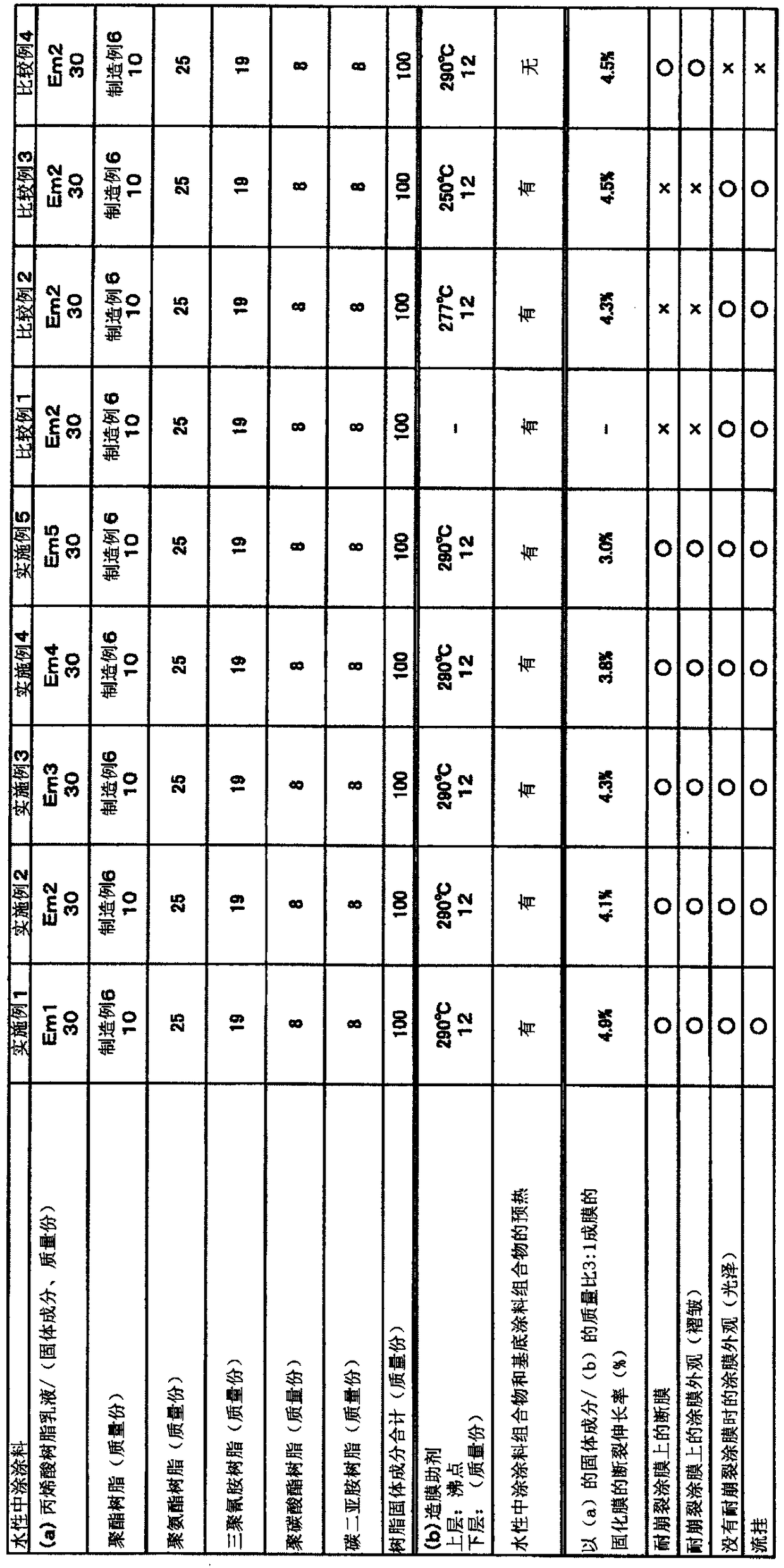

[0253] Hereinafter, although an Example is given and this invention is demonstrated in more detail, this invention is not limited to these Examples. In addition, in an Example, "part" means "part by mass" unless otherwise indicated.

[0254] Water-based intermediate coating composition

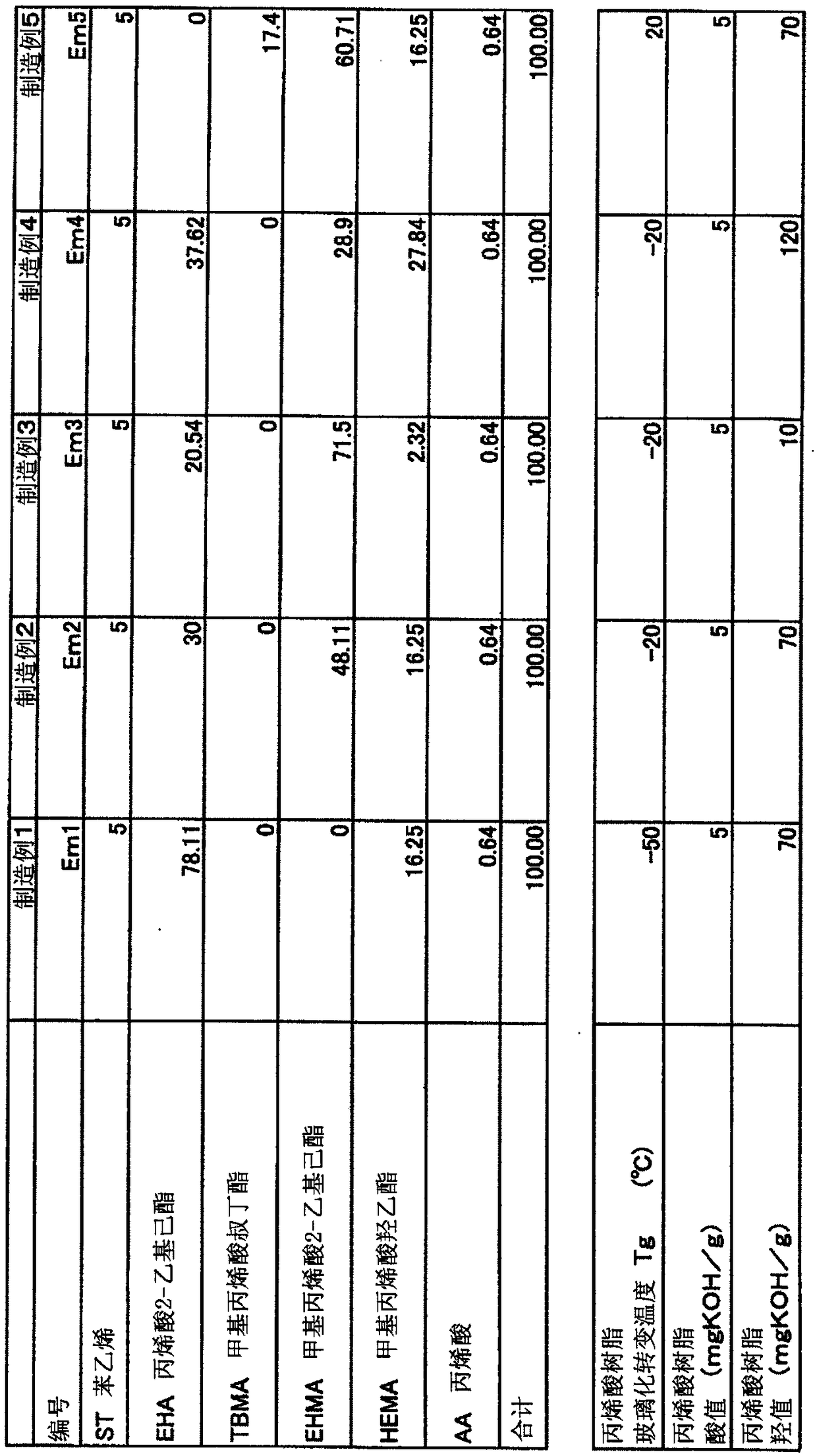

manufacture example 1~5

[0255] Production examples 1-5: Preparation of hydroxyl-containing acrylic resin emulsion

[0256] 445 parts of water and 5 parts of NEWCOL 293 (manufactured by Nippon Emulsifier Co., Ltd.) were charged into a reaction vessel for the production of a common acrylic resin emulsion equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser, and a nitrogen introduction pipe. While stirring, the temperature was raised to 75°C. A mixture of 24.6 parts of the monomer mixture shown in Table 1, 240 parts of water, and 30 parts of NEWCOL 293 (manufactured by Nippon Emulsifier Co., Ltd.) was emulsified using a homogenizer, and the monomer pre-emulsion was stirred for 3 hours. Add dropwise to the above reaction vessel. Simultaneously with the dropping of the monomer pre-emulsion, an aqueous solution in which 1 part of APS (ammonium persulfate) as a polymerization initiator was dissolved in 50 parts of water was evenly added dropwise to the above-mentioned reaction ve...

manufacture example 6

[0266] Manufacturing example 6: Preparation of hydroxyl-containing polyester resin

[0267] Add 25.6 parts of isophthalic acid, 22.8 parts of phthalic anhydride, 5.6 parts of adipic acid, 19.3 parts of trimethylolpropane, 26.7 parts of neopentyl glycol, 17.5 parts of ε-caprolactone, 2 0.1 part of butyltin oxide was mixed and stirred while raising the temperature to 170°C. Thereafter, the temperature was raised to 220° C. over 3 hours until the acid value became 8 mgKOH / g while removing water produced by the condensation reaction. Next, 7.9 parts of trimellitic anhydride was added, and it was made to react at 150 degreeC for 1 hour, and the polyester resin whose acid value was 40 mgKOH / g was obtained. Furthermore, after cooling to 100°C, 11.2 parts of butyl cellosolve were added and stirred until uniform, and after cooling to 60°C, 98.8 parts of ion-exchanged water and 5.9 parts of dimethylethanolamine were added to obtain a solid content of 50% by mass and a solid content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com