Hydroxyl-terminated polyester resin for co-extrusion extinction powder paint

A matte powder coating and hydroxyl-terminated polyester technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of increased external influencing factors, high requirements for active resin, and increased difficulty, and achieve good storage stability. The effect of stability, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

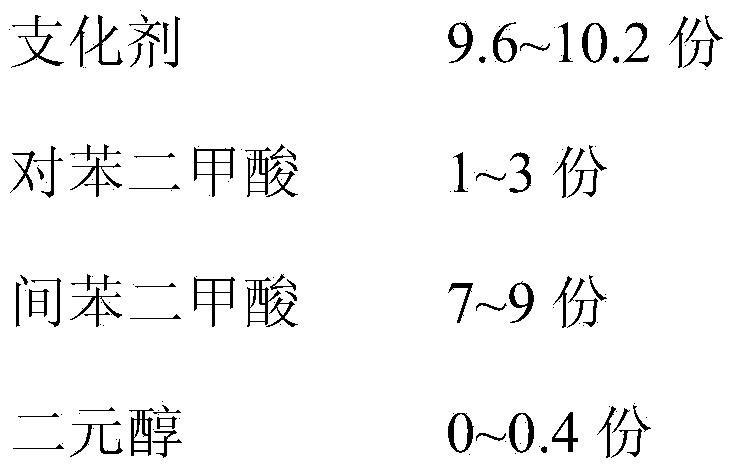

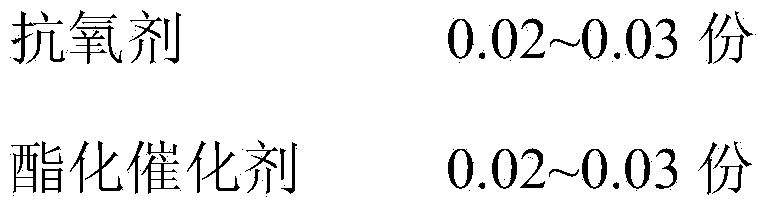

[0020] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coatings, comprising the following components by weight:

[0021]

[0022] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coating comprises the following steps:

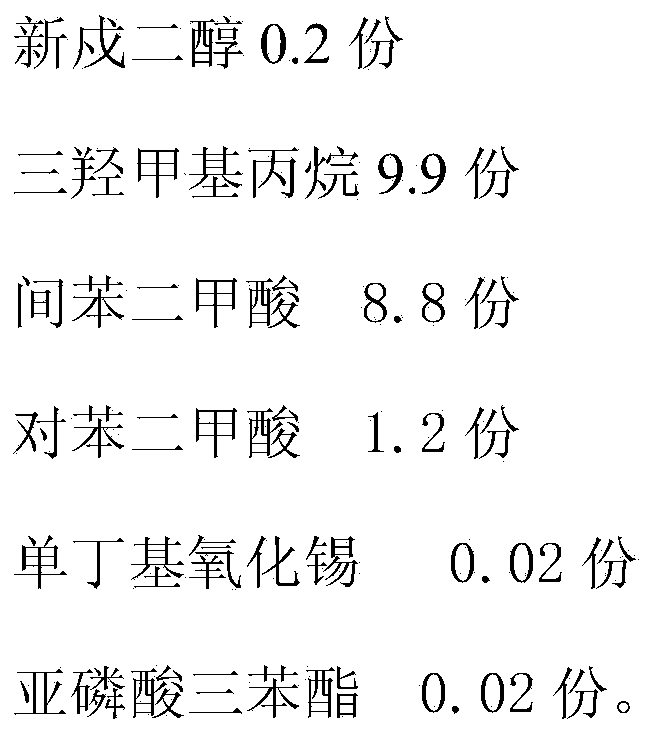

[0023] a. Esterification process: In a synthetic reaction vessel, put 0.2 parts of neopentyl glycol and 9.9 parts of trimethylolpropane into the material and heat until the material melts. The heating temperature is 80°C, and then 8.8 parts of isophthalic acid, 1.2 parts of terephthalic acid and 0.02 parts of monobutyltin oxide, after sealing the kettle, gradually heat the reaction in a nitrogen atmosphere, slowly raise the temperature to 230°C and maintain it until no distillate is formed. At this time, the acid value of the reactant is 4.6 mgKOH / g;

[0024] b. Vacuum process: Add 0.02 parts of triphenyl phosphite antioxidant to the reactant obtained in the esterification process, and react when th...

Embodiment 2

[0026] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coatings, comprising the following components by weight:

[0027]

[0028] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coating comprises the following steps:

[0029] a. Esterification process: In the synthesis reaction vessel, put 0.12 parts of neopentyl glycol and 10.0 parts of trimethylolpropane into the material and heat until the material melts. The heating temperature is 70° C., and then 7.6 parts of isophthalic acid, 2.5 parts of terephthalic acid and 0.026 parts of monobutyltin oxide, after sealing the kettle, gradually heat the reaction in a nitrogen atmosphere, slowly raise the temperature to 235°C and maintain it until no distillate is formed. At this time, the acid value of the reactant is 4.3 mgKOH / g;

[0030] b. Vacuum process: Add 0.026 parts of triphenyl phosphite antioxidant to the reactant obtained in the esterification process, and react...

Embodiment 3

[0032] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coatings, comprising the following components by weight:

[0033]

[0034] A kind of hydroxyl-terminated polyester resin for co-extrusion matting powder coating comprises the following steps:

[0035] a. Esterification process: In the synthesis reaction vessel, put 10.1 parts of trimethylolpropane into the material and heat until the material melts at a temperature of 90°C, then put 8 parts of isophthalic acid, 2 parts of terephthalic acid and 0.023 parts of monobutyltin oxide, after sealing the kettle, gradually heat the reaction in a nitrogen atmosphere, slowly raise the temperature to 235°C and maintain it until no distillate is formed. At this time, the acid value of the reactant is 4.0mgKOH / g;

[0036] b. Vacuum process: Add 0.023 parts of triphenyl phosphite antioxidant to the reactant obtained in the esterification process, and react when the temperature is lowered to 200°C and the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com