PU curable powder paint polyester resin excellent in cold resistance and production method

A polyester resin and powder coating technology, applied in the polyester resin field, can solve the problems of poor weather resistance, loss of coating performance, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

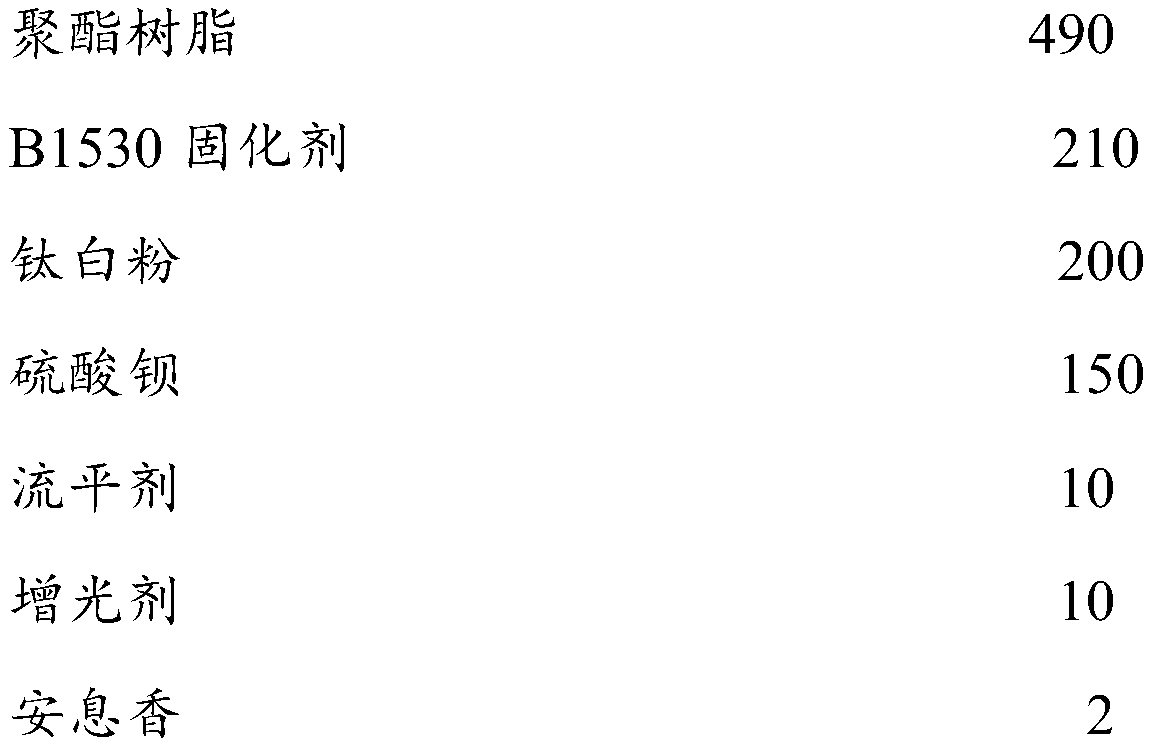

Examples

Embodiment 1

[0054] The preparation method of the PU solidified powder coating polyester resin with excellent cold resistance comprises the following steps:

[0055] (1) Add 15mol of terephthalic acid, 15mol of 3,3-tetramethylene glutaric acid, 15mol of N-butyldiethanolamine, 15mol of 1,4-di(hydroxymethyl)cyclohexane and catalyst into the reactor, first After fully melting at 120°C and stirring evenly, slowly raise the temperature to 185°C at a heating rate of 5°C / h and keep it warm for 3 hours to obtain a mixed material;

[0056] The polymerization catalyst is 2-octylsuccinate di(tributyltin), and the consumption is 0.12mol;

[0057] (2) When the acid value is reduced to 85mgKOH / g, add 10mol resorcinol-O, O'-diacetic acid, 10mol hydrogenated ricinoleic acid and 12mol neopentyl glycol to the above mixed material, and then Gradually raise the temperature at a rate of 10°C / h to 235°C, fully react for 6 hours, react until no obvious distillate is distilled out, add antioxidant tetrakis[β-(3,...

Embodiment 2

[0061] The preparation method of the PU solidified powder coating polyester resin with excellent cold resistance comprises the following steps:

[0062] (1) Add 12mol of terephthalic acid, 18mol of 3,3-tetramethylene glutaric acid, 12mol of N-butyldiethanolamine, 16mol of 1,4-di(hydroxymethyl)cyclohexane and catalyst into the reactor, first After fully melting at 120°C and stirring evenly, slowly raise the temperature to 185°C at a heating rate of 5°C / h and keep it warm for 3 hours to obtain a mixed material;

[0063] The polymerization catalyst is 2-octylsuccinate di(tributyltin), and the consumption is 0.12mol;

[0064] (2) When the acid value is reduced to 85mgKOH / g, add 10mol resorcinol-O, O'-diacetic acid, 12mol hydrogenated ricinoleic acid and 12mol neopentyl glycol to the above mixed material, and then Gradually raise the temperature at a rate of 10°C / h to 235°C, fully react for 6 hours, react until no obvious distillate is distilled out, add antioxidant tetrakis[β-(3,...

Embodiment 3

[0068] The preparation method of the PU solidified powder coating polyester resin with excellent cold resistance comprises the following steps:

[0069] (1) Add 10mol of terephthalic acid, 20mol of 3,3-tetramethylene glutaric acid, 15mol of N-butyldiethanolamine, 15mol of 1,4-di(hydroxymethyl)cyclohexane and catalyst into the reactor, first After fully melting at 120°C and stirring evenly, slowly raise the temperature to 180°C at a heating rate of 6°C / h and keep it warm for 3 hours to obtain a mixed material;

[0070] The polymerization catalyst is 2-octylsuccinate di(tributyltin), and the consumption is 0.1mol;

[0071] (2) When the acid value is reduced to 85 mgKOH / g, add 10 mol of resorcinol-O, O'-diacetic acid, 10 mol of hydrogenated ricinoleic acid and 10 mol of neopentyl glycol to the above mixed material, and then Gradually raise the temperature at a rate of 10°C / h to 235°C, fully react for 6 hours, react until no obvious distillate is distilled out, add antioxidant te...

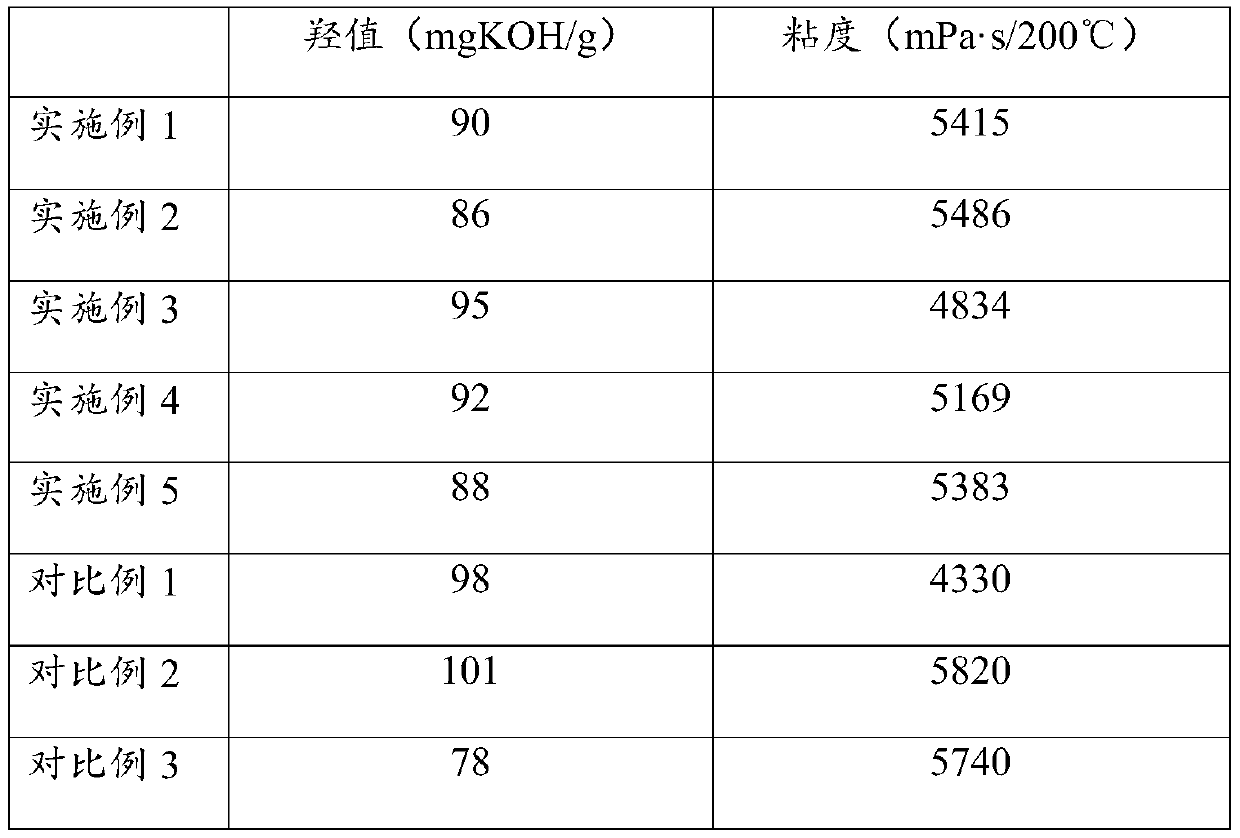

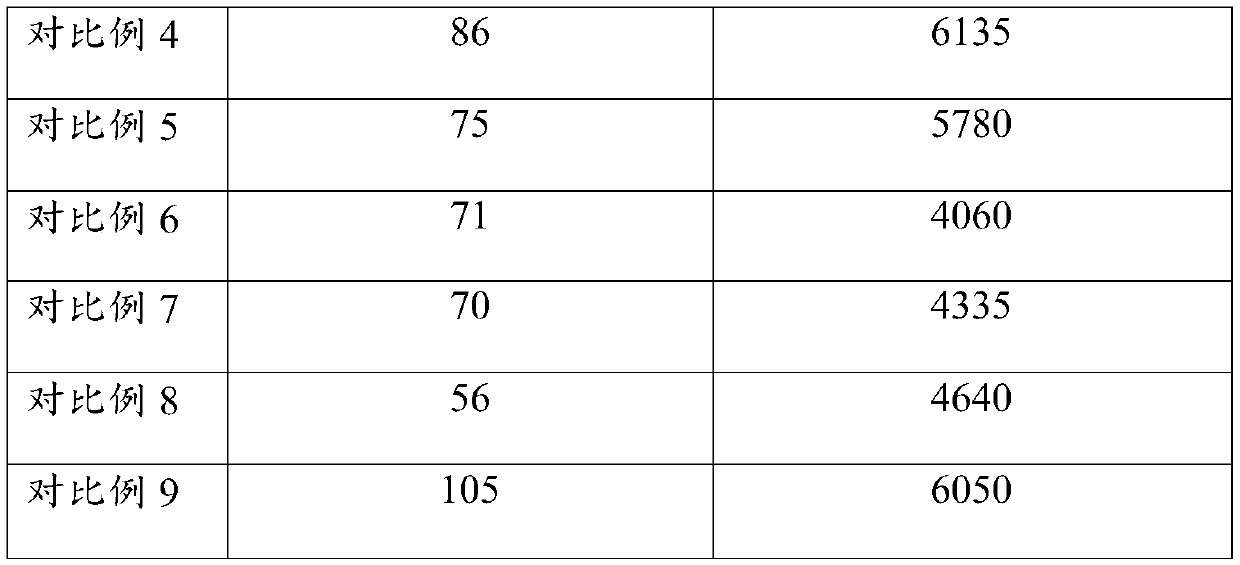

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com