Method for improving pinholes and levelling property of hydroxyalkylamide/polyester powder paint

A hydroxyalkylamide, polyester powder technology, applied in polyurea/polyurethane coatings, powder coatings, polyester coatings, etc., to reduce the speed of curing, help thick coating, and improve the effect of leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

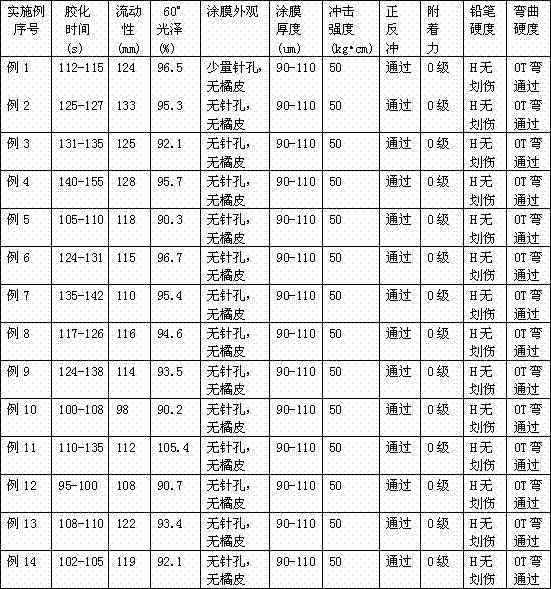

Examples

Embodiment 1

[0018] Dissolve isophorone diisocyanate in a solvent and add it dropwise into trimethylolpropane to prepare highly branched polyurethane (HBPU-1). The molecular weight of the obtained HBPU-1 is 2000, and the degree of branching is 0.7; Precipitate HBPU-1 with water, suction filter and dry the precipitate to obtain HBPU-1 powder; mix HBPU-1 powder with hydroxyalkylamide / polyester powder coating, in the mixture, HBPU-1 powder and hydroxyalkylamide The weight ratio of the carboxylic acid polyester contained in the polyester powder coating is 0.01:1, and then the mixture is melted, extruded, and pressed into sheets by a twin-screw extruder, and the temperature in the first zone of the twin-screw extruder is 90°C, the temperature in the second zone is 100°C; the sheet is ground into a fine powder with a colloid mill, and the fine powder is sieved with a 160-mesh filter to obtain a modified hydroxyalkylamide / polyester powder coating.

[0019] The modified hydroxyalkylamide / polyester...

Embodiment 2

[0021] Dissolving isophorone diisocyanate and 1,4-butanediol in a solvent for prepolymerization to form NCO-terminated polyurethane prepolymer. Then, the prepolymer was added dropwise into trimethylolpropane to react to prepare highly branched polyurethane (HBPU-2). The molecular weight of the prepared HBPU-2 was 6000, and the degree of branching was 0.6. Precipitate HBPU-2 with water, suction filter and dry the precipitate to obtain HBPU-2 powder; mix HBPU-2 powder with hydroxyalkylamide / polyester powder coating, in the mixture, HBPU-2 powder and hydroxyalkylamide The weight ratio of the carboxylic acid polyester contained in the polyester powder coating is 0.02:1, and then the mixture is melted, extruded, and tableted by a twin-screw extruder to form a sheet. The temperature in the first zone of the twin-screw extruder is 90°C, the temperature in the second zone is 100°C; the sheet is ground into a fine powder with a colloid mill, and the fine powder is sieved with a 160-mes...

Embodiment 3

[0024] Dissolving 2,4-toluene diisocyanate and 1,2-propanediol in a solvent for prepolymerization into NCO-terminated polyurethane prepolymer. Then the prepolymer is added dropwise in trimethylolethane to continue the reaction, and finally the epoxy resin is added to react to obtain highly branched polyurethane (HBPU-3). The molecular weight of the HBPU-3 obtained is 12000, and 0.52. Precipitate HBPU-3 with water, filter and dry the precipitate to obtain HBPU-3 powder; mix HBPU-3 powder with hydroxyalkylamide / polyester powder coating, in the mixture, HBPU-3 powder and hydroxyalkylamide The weight ratio of the carboxylic acid polyester contained in the polyester powder coating is 0.05:1, and then the mixture is melted, extruded, and tableted by a twin-screw extruder to form a sheet. The temperature in the first zone of the twin-screw extruder is 95°C, the temperature in the second zone is 105°C; the sheet is ground into a fine powder with a colloid mill, and the fine powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow length | aaaaa | aaaaa |

| flow length | aaaaa | aaaaa |

| flow length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com