Sectional type water cooling mold

A segmented, water-cooled technology, used in household appliances, other household appliances, tires, etc., can solve the problems of the same cooling conditions and the vacuum on the wheel surface, and achieve the effects of convenient production, strong cooling strength, and easy operation and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

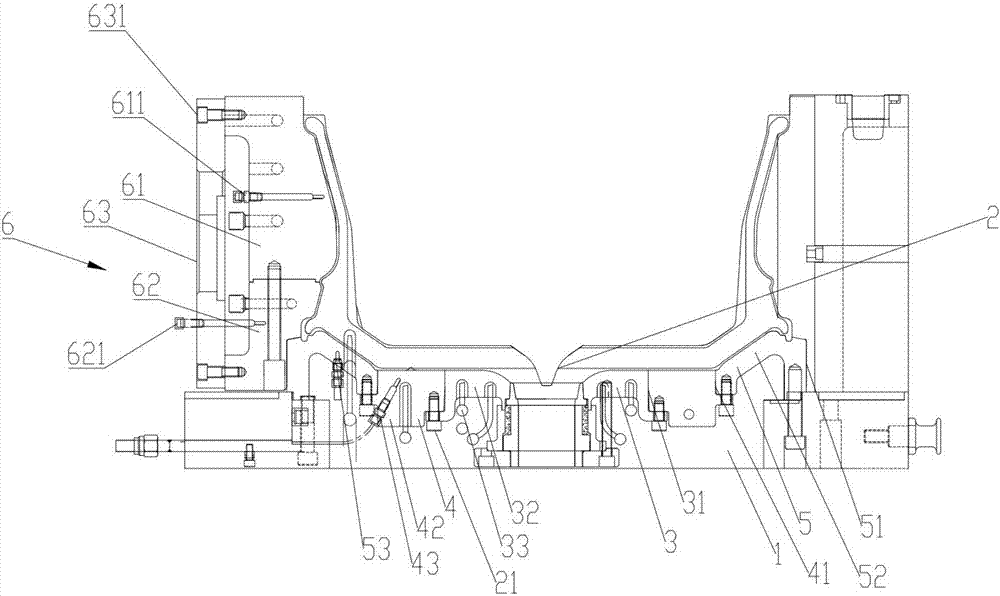

[0030] Such as figure 1 As shown, a segmented water-cooled mold includes a bottom plate 1, a bottom mold 2 arranged on the bottom plate 1, and a side mold 6 connected to the edge of the bottom mold 2. The bottom mold 2 is provided with a first The lower mold 3, the second lower mold 4 and the third lower mold 5 are sequentially arranged between the first lower mold 3 and the bottom plate 1, the first lower mold 3 and the second lower mold 4, the second lower mold 4 and the third lower mold The mold 5, the third lower mold 5 and the bottom plate 1 are seamlessly connected by locking bolts 21; the connection between the first lower mold 3 and the second lower mold 4 is provided with a first lower Die wall 31, the junction of the second lower mold 4 and the third lower mold 5 is provided with the second lower mold wall 41 connected to the bottom mold 2, and the junction of the third lower mold 5 and the bottom plate 1 is provided with the bottom mold 2 The third lower mold wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com