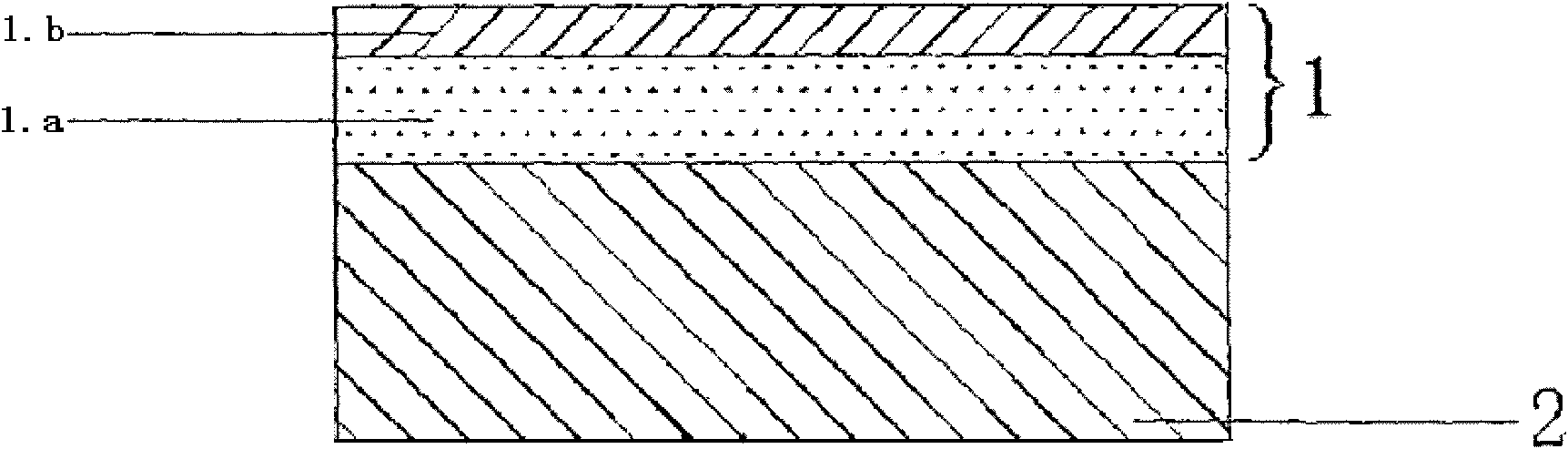

Excessive-plating prevention dual-layer thin film as well as preparation method and application thereof

A double-layer film and thin-layer technology, applied in the field of solar energy, can solve problems such as corrosion, inability to overcoat, and disappearance of double-layer anti-reflection film characteristics, so as to improve product yield and stability, simplify the preparation process, and prevent overcoating. The effect of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

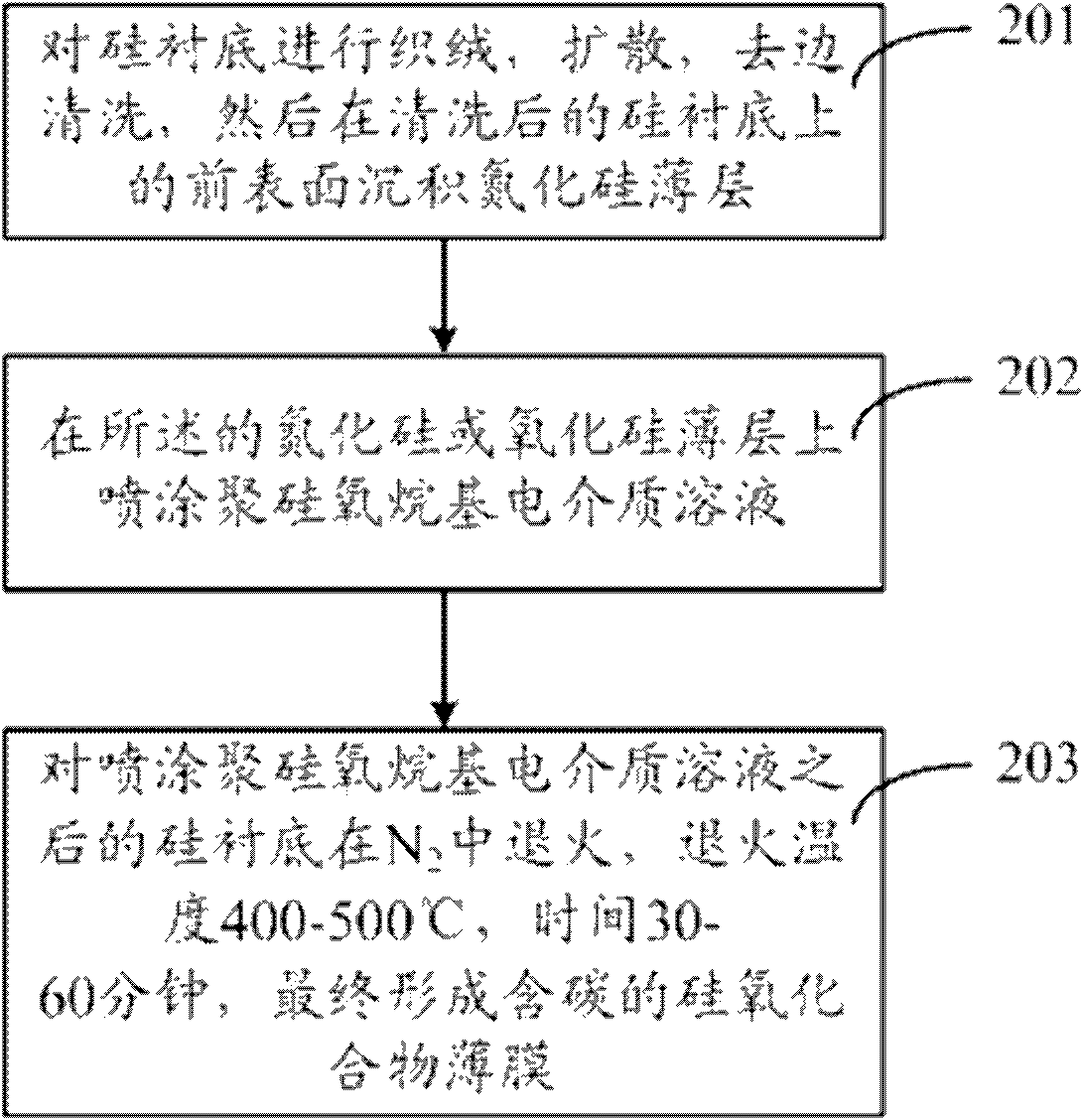

[0028] figure 2 Shown is the flow chart of the preparation method embodiment of double-layer thin film of the present invention, and it comprises the following steps:

[0029] Step 201, performing weaving, diffusion, edge cleaning on the silicon substrate, and then depositing a silicon nitride thin layer on the front surface of the cleaned silicon substrate;

[0030] Step 202, spraying polysiloxane-based dielectric solution on the silicon nitride or silicon oxide thin layer;

[0031] Step 203, spraying the silicon substrate after the polysiloxane-based dielectric solution on N 2 Medium annealing, the annealing temperature is 400-500° C., and the time is 30-60 minutes, finally forming a carbon-containing silicon oxide film.

[0032] Before step 203 is performed, the silicon substrate may be placed on a hot plate and dried at a temperature of 200° C. for 30 seconds.

[0033] In the present invention, a thin layer of silicon oxide may also be deposited on the surface of the s...

Embodiment 1

[0039] 1. The silicon substrate is processed according to the conventional production line process: P-type polysilicon is used, the surface of the silicon substrate is woven with acidic solution, POCl 3 The liquid source is diffused to form a PN junction, edge cleaning is performed, silicon nitride is deposited by PECVD, and Ag and Al electrodes are screen-printed on the back.

[0040] 2. Deposit hydrophobic dielectric film by spraying method: configure IC1-200 and isopropanol according to the volume ratio of 1:1 to form a diluted IC1-200 solution, and then use 10ml / min on the spraying equipment PV-360 The spraying speed is sprayed once, and the spraying speed determines the thickness of the film, and the thickness of the film obtained at this speed is 25nm.

[0041] 3. Place the silicon substrate sprayed with IC1-200 on a hot plate, and dry it in the air at 200°C for 30 seconds to remove isopropanol and other organic components in the film.

[0042] 4. In the air, place the ...

Embodiment 2

[0044] 1. The silicon substrate is processed according to the conventional production line process: P-type polysilicon is used, the surface of the silicon substrate is woven with acidic solution, POCl 3 The liquid source is diffused to form a PN junction, edge cleaning is performed, silicon nitride is deposited by PECVD, and Ag and Al electrodes are screen-printed on the back.

[0045] 2. Deposit hydrophobic dielectric film by spraying method: configure IC1-200 and isopropanol at a volume ratio of 1:1 to form a diluted IC1-200 solution, and then spray it on PV-360 at a rate of 20ml / min Spraying was carried out at a spraying speed, spraying twice, and the thickness of the obtained film was 100 nm.

[0046] 3. Place the silicon substrate sprayed with IC1-200 on a hot plate, and dry it in air at 200°C for 30 seconds to remove isopropanol and other organic components in the film.

[0047] 4. In the air, place the silicon substrate prepared in step 3 on a hot plate and anneal at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com