Preparation method of graphene-nickel phosphide composite coating and prepared coating

A composite coating and graphene technology, applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems of different reduction degrees, poor controllability, and affecting the comprehensive performance of composite coatings, and achieve accelerated diffusion, Dense structure, improvement of pinhole and air bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

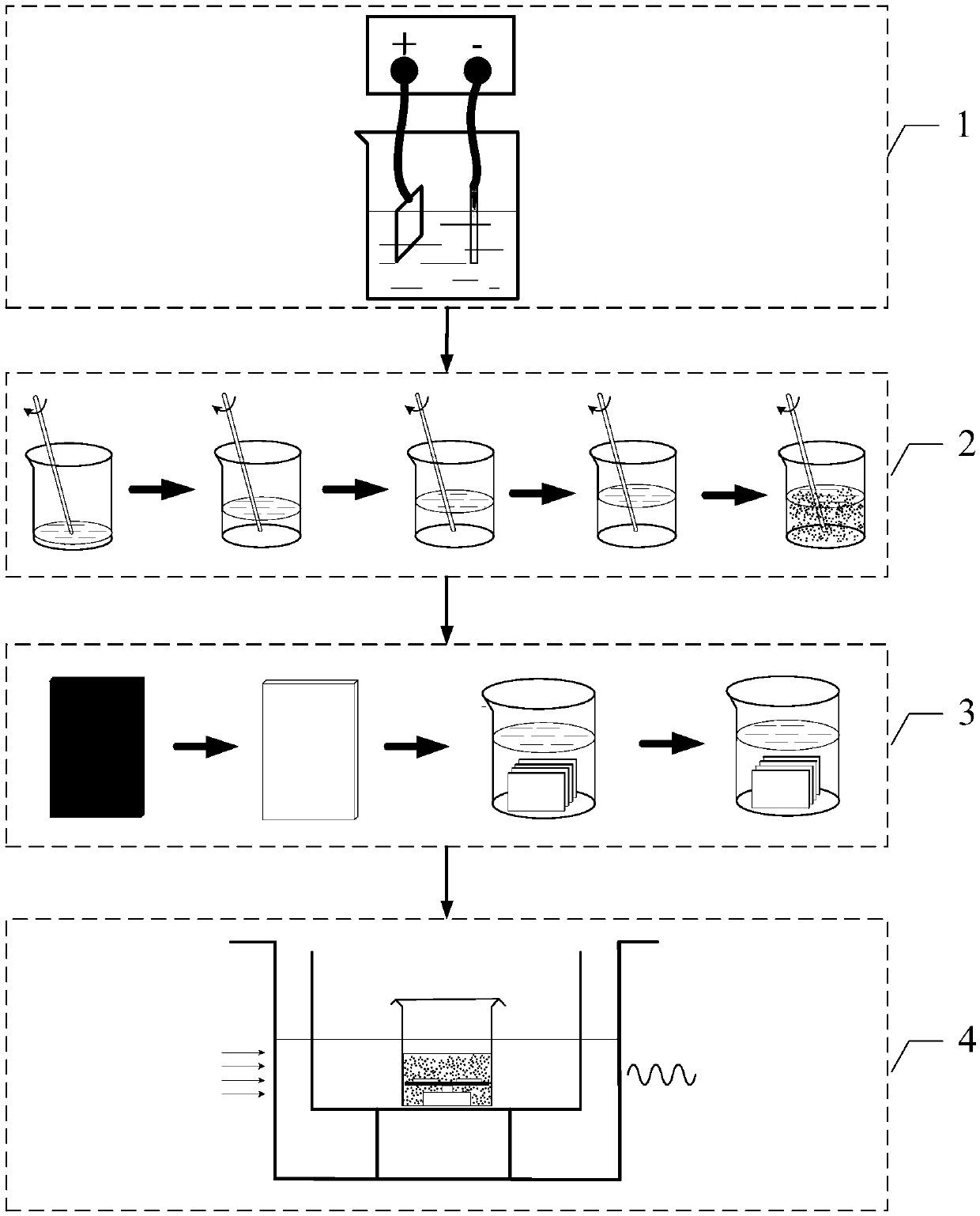

[0051] see figure 1 , which is a schematic flow chart of a method for preparing a graphene-nickel phosphide composite coating in an embodiment of the present invention, and the method for preparing a graphene-nickel phosphide composite coating described in this embodiment includes the following steps:

[0052] (1) Preparation of graphene:

[0053] Place the graphite sheet on the positive pole of the DC power supply, place the platinum wire electrode on the negative pole of the DC power supply, immerse in the electrolyte of 0.5mol / L ammonium sulfate aqueous solution, change the applied voltage value and voltage action time, and peel off. The obtained graphene was vacuum-filtered, washed with deionized water, transferred to N-methylpyrrolidone, ultrasonically dispersed for 30 minutes, and then left to stand for 48 hours. Take the upper layer solution for vacuum filtration and deionized water cleaning, transfer the collected graphene microflakes to an aqueous solution of sodium ...

Embodiment 2

[0066] The preparation method of the graphene-nickel phosphide composite coating described in the present embodiment comprises the steps:

[0067] (1) Preparation of graphene:

[0068] Place the graphite sheet on the positive pole of the DC power supply, place the platinum wire electrode on the negative pole of the DC power supply, immerse in the electrolyte of 0.5mol / L ammonium sulfate aqueous solution, change the applied voltage value and voltage action time, and peel off. The obtained graphene was vacuum-filtered, washed with deionized water, transferred to N-methylpyrrolidone, ultrasonically dispersed for 30 minutes, and then left to stand for 48 hours. Take the upper layer solution for vacuum filtration and deionized water cleaning, transfer the collected graphene microflakes to an aqueous solution of sodium dodecyl sulfate for ultrasonic dispersion for 3h, and carry out surface modification on the graphene microchips to make the graphene microchips able to disperse even...

Embodiment 3

[0080] The preparation method of the graphene-nickel phosphide composite coating described in the present embodiment comprises the steps:

[0081] (1) Preparation of graphene:

[0082] Place the graphite sheet on the positive pole of the DC power supply, place the platinum wire electrode on the negative pole of the DC power supply, immerse in the electrolyte of 0.5mol / L ammonium sulfate aqueous solution, change the applied voltage value and voltage action time, and peel off. The obtained graphene was vacuum-filtered, washed with deionized water, transferred to N-methylpyrrolidone, ultrasonically dispersed for 30 minutes, and then left to stand for 48 hours. Take the upper layer solution for vacuum filtration and deionized water cleaning, transfer the collected graphene microflakes to an aqueous solution of sodium dodecyl sulfate for ultrasonic dispersion for 3h, and carry out surface modification on the graphene microchips to make the graphene microchips able to disperse even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com