Expandable type building fireproof coating and preparation method thereof

An intumescent technology for fire-resistant coatings, applied in fire-resistant coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor fire-proof performance, poor anti-ultraviolet effect of fire-proof coatings, and short fire-proof time, and achieve the goal of coating Appearance and weather resistance, improvement of UV resistance, good effect of coating appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

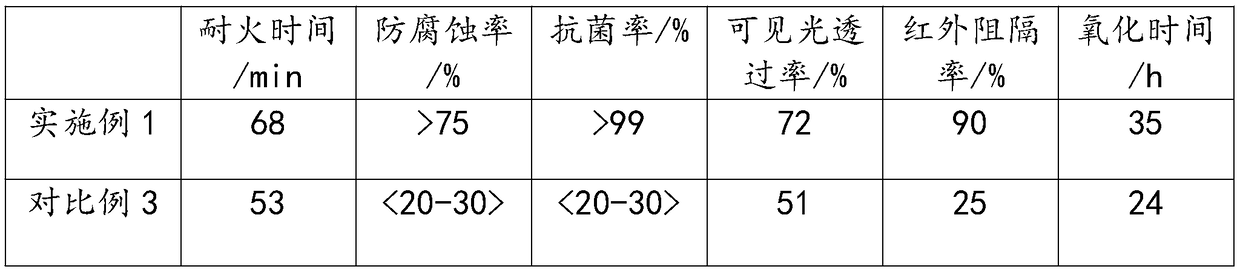

Examples

Embodiment 1

[0033]An intumescent architectural fireproof coating, the mass percentage of each raw material is 15% base material, 60% flame retardant, 5% auxiliary agent, 10% solvent and 10% filler;

[0034] The mass percentages of each raw material in the base material are respectively 40 parts of unsaturated polyester resin, 10 parts of epoxy resin, 40 parts of modified high-performance high-chlorinated polyethylene resin and 10 parts of modified composite nano-oxide slurry;

[0035] The mass percentages of the raw materials in the flame retardant are 60% ammonium polyphosphate, 10% pentaerythritol and 30% melamine.

[0036] A preparation method of intumescent building fireproof coating, comprising the following steps:

[0037] 1) Preparation of mixed liquid A: weigh the unsaturated polyester resin and add it to the stirred reactor, and then add styrene, methyl ethyl ketone peroxide, cobalt naphthenate and liquid paraffin to the stirred reactor, and stir for 20 minutes -40min, prepare m...

Embodiment 2

[0050] An intumescent architectural fireproof coating, the mass percentage of each raw material is 30% base material, 30% flame retardant, 5% auxiliary agent, 30% solvent and 5% filler;

[0051] The mass percentages of each raw material in the base material are respectively 30 parts of unsaturated polyester resin, 20 parts of epoxy resin, 40 parts of modified high-performance high-chlorinated polyethylene resin and 10 parts of modified composite nano-oxide slurry;

[0052] The mass percentages of the raw materials in the flame retardant are respectively 40% ammonium polyphosphate, 20% pentaerythritol and 40% melamine.

[0053] The preparation method of this a kind of expansive building fireproof coating is identical with embodiment 1;

[0054] The preparation method of described modified high performance high chlorinated polyethylene resin is identical with embodiment 1;

[0055] The preparation method of the modified composite nano-oxide slurry is the same as that in Example...

Embodiment 3

[0057] An intumescent architectural fireproof coating, the mass percentage of each raw material is 28% base material, 56% flame retardant, 1% auxiliary agent, 10% solvent and 5% filler;

[0058] The mass percentages of each raw material in the base material are respectively 55 parts of unsaturated polyester resin, 7 parts of epoxy resin, 28 parts of modified high-performance high-chlorinated polyethylene resin and 10 parts of modified composite nano-oxide slurry;

[0059] The mass percentages of the raw materials in the flame retardant are respectively 40% ammonium polyphosphate, 20% pentaerythritol and 40% melamine.

[0060] The preparation method of this a kind of expansive building fireproof coating is identical with embodiment 1;

[0061] The preparation method of described modified high performance high chlorinated polyethylene resin is identical with embodiment 1;

[0062] The preparation method of the modified composite nano-oxide slurry is the same as that in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com