Ti-Fe-Ni-C series reaction thermal spraying composite powder and preparation technique thereof

A technology of composite powder and heat of reaction, applied in metal material coating process, coating, molten spraying, etc., can solve the problems of limitation, low coating wear resistance, unfavorable coating performance improvement, etc., and achieve porosity Low, not easy to separate, reduce the effect of TiC aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

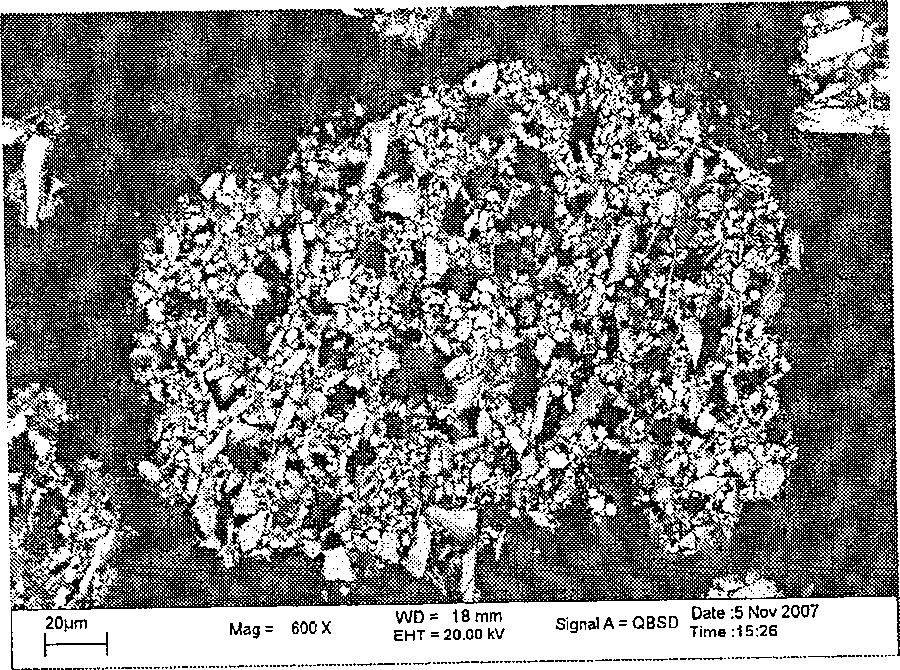

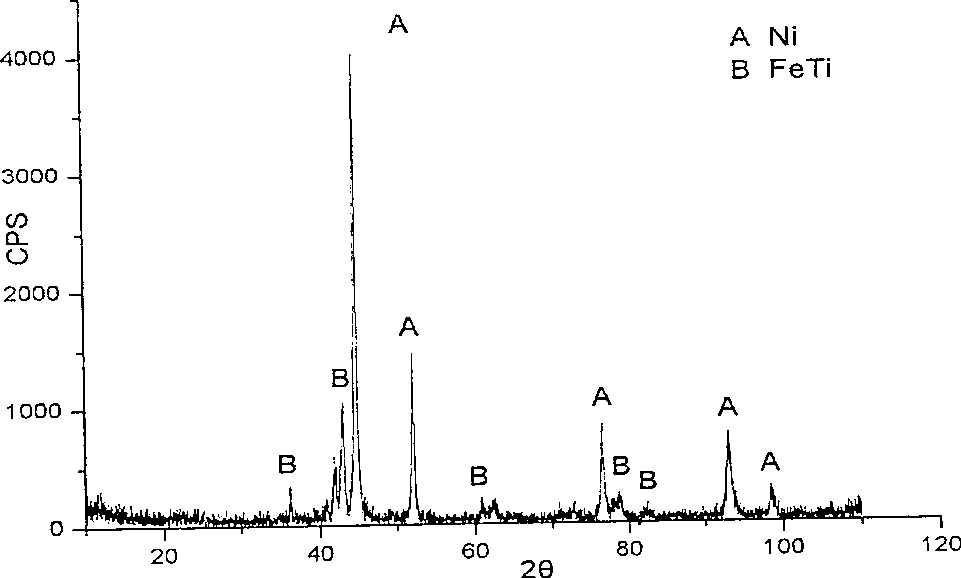

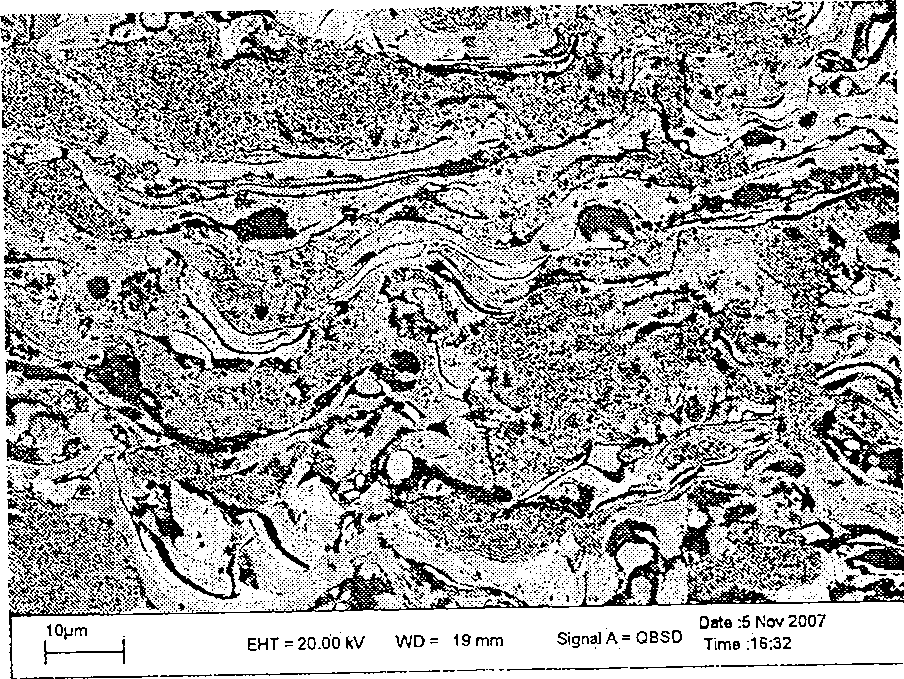

Image

Examples

Embodiment Construction

[0027] The raw material powder that the present invention adopts is TiFe powder, Ti powder, Ni powder, Fe powder and sucrose, and prepared Ti-Fe-Ni-C system reactive thermal spraying composite powder composition is as shown in Table 1, and its concrete technological process is as follows :

[0028] 1) Mix TiFe powder (2-10 μm), Ti powder (2-10 μm), Ni powder (2-5 μm), Fe powder (2-5 μm) and sucrose according to the ratio;

[0029] 2) The mixed raw material powder is wet milled on a ball mill for 24 to 72 hours, the volume ratio of the steel ball to the raw material mixture used is 4:1, the speed of the ball mill is 120rpm, and the ball milling medium is alcohol;

[0030] 3) Dry the uniformly mixed slurry after ball milling at 45-60°C for 4-12 hours;

[0031] 4) Put the block-shaped mixed powder after drying the slurry into a heat treatment furnace protected by nitrogen, and the thickness of the charge is 2-10cm;

[0032] 5) First pass nitrogen protection for 5-10 minutes, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com