Electron beam evaporative vacuum coating equipment

A vacuum coating machine and electron beam evaporation technology, applied in vacuum evaporation coating, ion implantation coating, sputtering coating and other directions, can solve the problems of complex mechanism, low coating efficiency, low uniformity and repeatability of coating structure, etc. The effect of high coating efficiency, high uniformity and repeatability, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

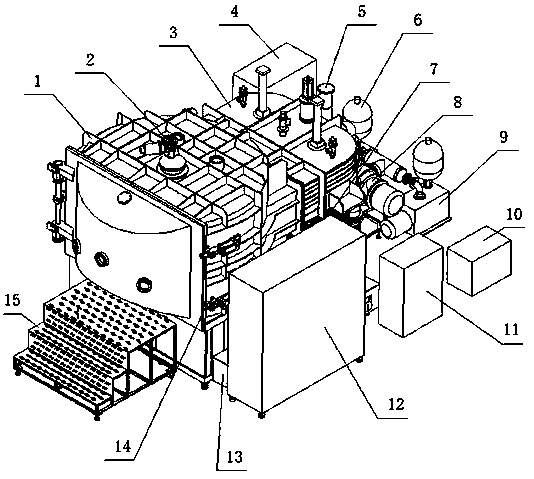

[0015] refer to figure 1 , an electron beam evaporation vacuum coating machine, including 1 set of cavity assembly 1, 1 set of umbrella frame assembly 2, 1 set of high valve assembly 3, 1 set of cryogenic system 4, 1 set of piping system 5, 2 oil filters Components 6, 2 diffusion pumps 7, 1 Roots pump 8, 2 mechanical pumps 9, 1 set of ion source components 10, 1 set of electron gun components 11, 1 set of electric control cabinet components 12, 1 set of trunking components 13, Two door clamping assemblies 14 and a set of pedal assemblies 15; the umbrella stand assembly 2 is fixed on the cavity assembly 1, the high valve assembly 3 is connected with the cavity assembly 1, the high valve assembly 3, The diffusion pump 7, the Roots pump 8 and the mechanical pump 9 are connected together through the pipeline system 5, and the door clamping assembly 14 is installed on the chamber assembly 1, and is used to control the pressing and closing of the door and the chamber on the chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com