Directional ultrahigh-velocity spraying method and device based on laser induced shock wave technology

A shock wave and ultra-high-speed technology, applied in the field of parts processing and remanufacturing, can solve the problems of difficult control of explosion parameters, poor safety, and low spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

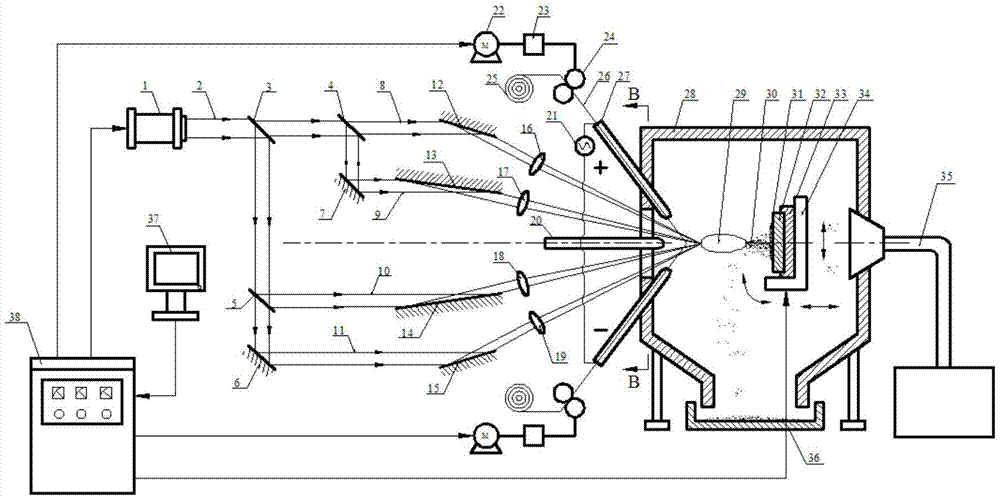

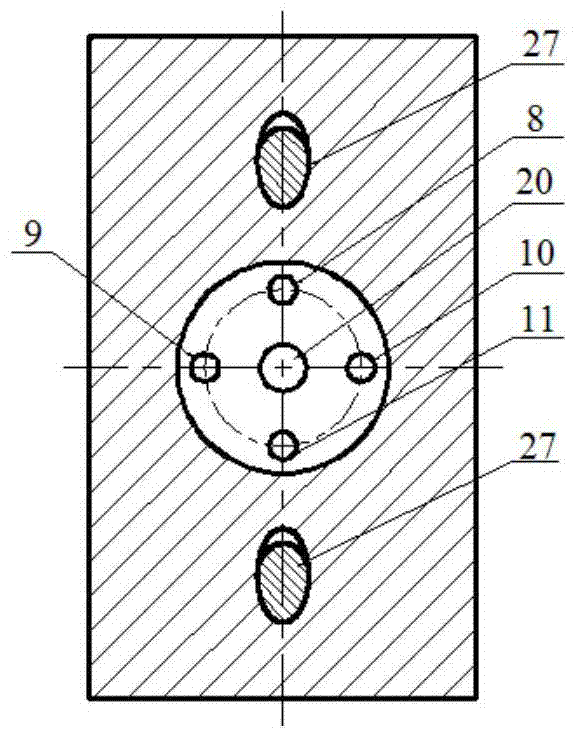

[0037] A directional ultra-high-speed spraying device based on laser shock wave technology provided by the present invention includes a laser generator 1, a light guiding and splitting system, an arc liquid making system, a workpiece fixture system, a recycling system, and a control system. Wherein the light guiding and splitting system includes the incident main laser pulse beam 2, the first beam splitter 3, the second beam splitter 4, the third beam splitter 5, the first total reflection mirror 6, the second total reflection mirror 7, and the third total reflection mirror mirror 12, the fourth total reflection mirror 13, the fifth total reflection mirror 14, the sixth total reflection mirror 15, the first sub-laser pulse beam 8, the second sub-laser pulse beam 9, the third sub-laser pulse beam 10, the fourth Divide the laser pulse beam 11, the first focusing lens 16, the second focusing lens 17, the third focusing lens 18, the fourth focusing lens 19; the arc liquid making sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com