A kind of cr/crn/(ti, al, si, cr) n composite hard coating and preparation method thereof

A hard coating and coating technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problem of difficult to meet the user's requirements for the service life of the tool coating, the combination of the coating and the tool In order to avoid problems such as poor force and non-nanocrystalline structure of the structure, it can achieve the effects of good diffusivity, uniform coating structure and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

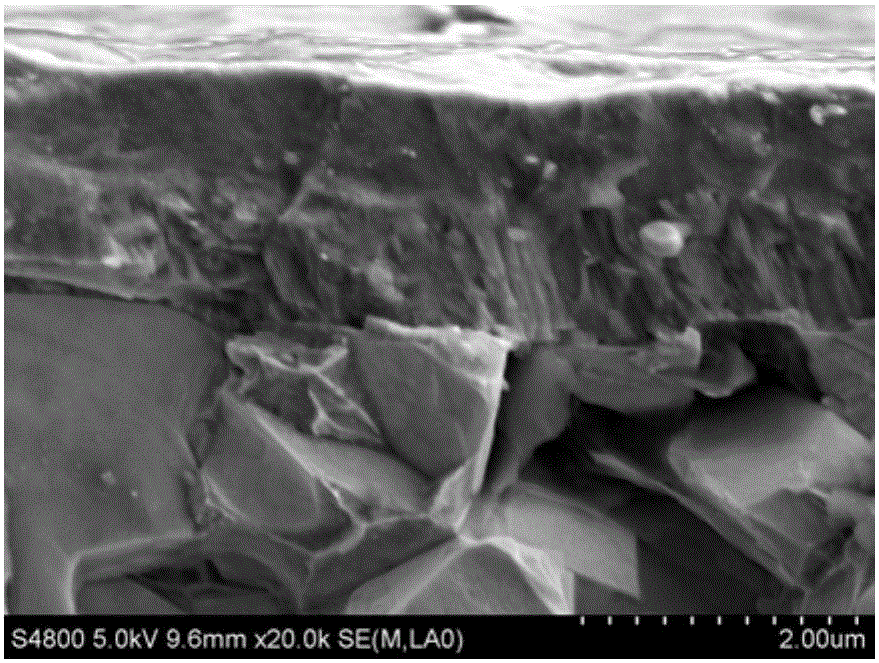

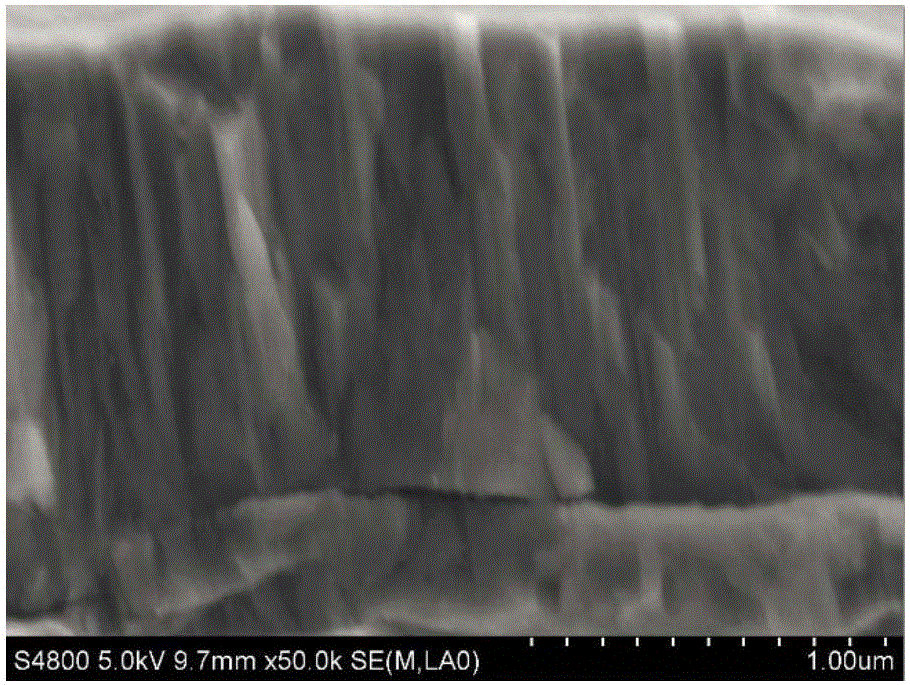

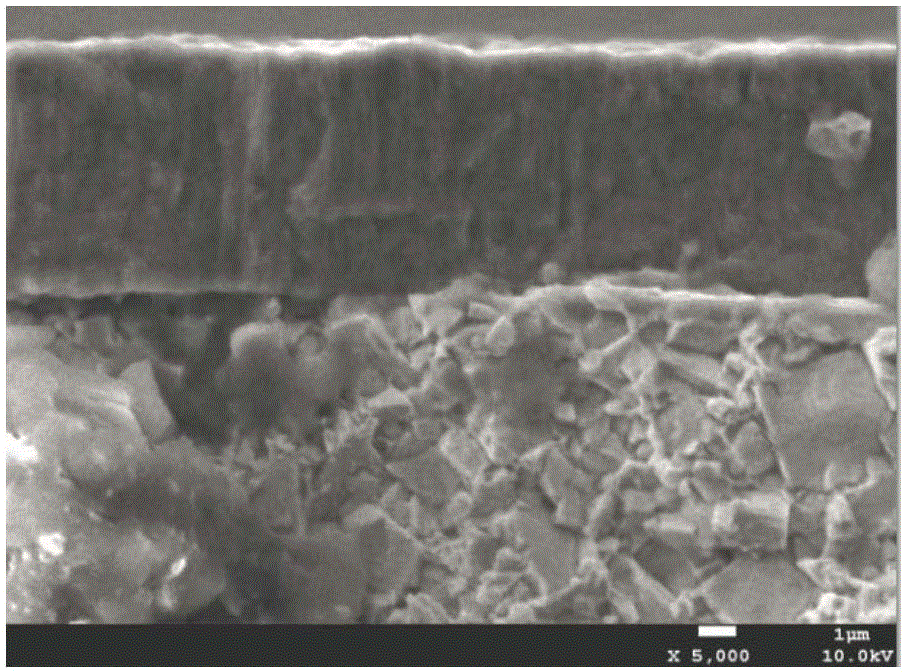

Image

Examples

Embodiment 1

[0034] 1) Put the cemented carbide taps after degreasing, sandblasting and ultrasonic cleaning by conventional methods into the coating chamber, and first vacuum the coating chamber to 5.0×10 -3 Pa, and then argon gas was introduced to make the total pressure in the coating chamber 3.0×10 -1 Pa, turn on the hot cathode ion column arc so that the current is 150A, and heat the tool for 150min;

[0035] 2) At a pressure of 1.8×10 -1 Under the protection of Pa argon gas, the DC bias voltage of the tool is controlled to -200V, the pulse bias voltage is -700V, and then the plasma generated by the hot cathode ion column arc with a current of 110A is used to bombard and clean the tool surface for 30 minutes;

[0036] 3) At a pressure of 8.0×10 -2 Under the protection of Pa argon gas, the Cr ingot is heated by a hot cathode ion column arc with a current of 200A to make it evaporate, and the tool is plated for 10 minutes to form a layer of Cr adhesion layer on the surface, and then th...

Embodiment 2

[0040] 1) Put the cemented carbide turning tool after degreasing, sandblasting and ultrasonic cleaning by conventional methods into the coating chamber, and first vacuum the coating chamber to 5.0×10 -3 Pa, and then argon gas was introduced to make the total pressure in the coating chamber 4.0×10 -1 Pa, turn on the hot cathode ion column arc to make the current 160A, and heat the tool for 100min;

[0041] 2) At a pressure of 1.5×10 -1 Under the protection of Pa argon gas, control the DC bias voltage of the tool to -150V, pulse bias voltage -600V, and then use the plasma generated by the hot cathode ion column arc with a current of 120A to bombard and clean the tool surface for 40min;

[0042] 3) At a pressure of 1.0×10 -1 Under the protection of Pa argon gas, the Cr ingot is heated by a hot cathode ion column arc with a current of 180A to evaporate it, and the tool is plated for 6 minutes to form a layer of Cr adhesion layer on the surface, and then the flow ratio of feeding...

Embodiment 3

[0046] 1) Put the cemented carbide drill bit after degreasing, sandblasting and ultrasonic cleaning by conventional methods into the coating chamber, and first vacuum the coating chamber to 5.0×10 -3 Pa, and then argon gas was introduced to make the total pressure in the coating chamber 3.0×10 -1 Pa, turn on the hot cathode ion column arc to make the current 140A, and heat the tool for 40min;

[0047] 2) At a pressure of 1.5×10 -1 Under the protection of Pa argon gas, control the DC bias voltage of the tool to -100V, and the pulse bias voltage to -500V, and then use the plasma generated by the hot cathode ion column arc with a current of 110A to bombard and clean the tool surface for 15 minutes;

[0048] 3) At a pressure of 1.2×10 -1 Under the protection of Pa argon gas, the Cr ingot is heated by a hot cathode ion column arc with a current of 210A to evaporate it, and the tool is plated for 7 minutes to form a layer of Cr adhesion layer on the surface, and then the flow rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com