Carbon nanotube/titanium dioxide composite film and preparation method and application thereof

A technology of nano-titanium dioxide and titanium dioxide, which is applied in the field of gas sensors, can solve the problems of complex preparation process of composite materials and low sensitivity of composite material conductivity sensors, and solve the problems of resistance drifting with the number of cycles, rapid recovery and complete recovery, and improvement The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

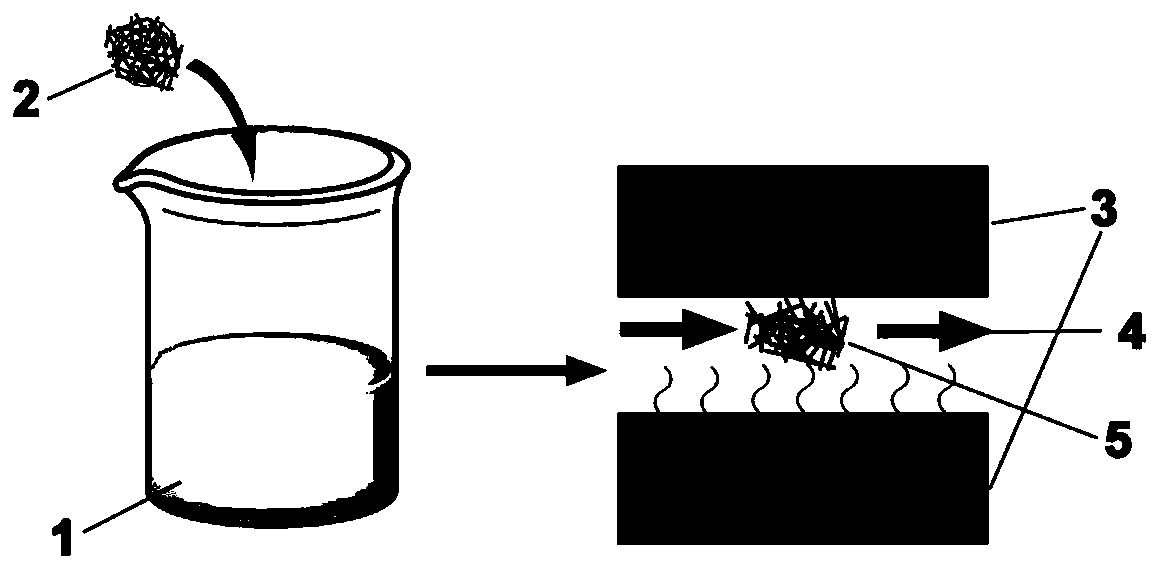

[0031] Such as figure 1 Shown, a kind of preparation method of carbon nanotube / titanium dioxide composite film comprises the following steps:

[0032] (1) Self-supporting, substrate-free and continuous single-walled carbon nanotube film prepared by chemical vapor deposition, the single-walled carbon nanotube film is tiled on a support ring, and the support ring is a circular copper ring;

[0033] Chemical vapor deposition uses xylene as a carbon source and ferrocene as a catalyst to grow carbon nanotubes in a tube furnace at 1200°C in a hydrogen-argon mixed gas environment to prepare single-walled carbon nanotube films; the prepared single-walled carbon nanotubes The tube film is self-supporting, has good mechanical strength, and does not need a substrate to ensure that the film remains intact during the subsequent in-situ hydrolysis process;

[0034] (2) Tetrabutyl titanate and ethanol are uniformly mixed at a volume ratio of 1:5 to obtain a mixed solution, and the circular ...

Embodiment 1

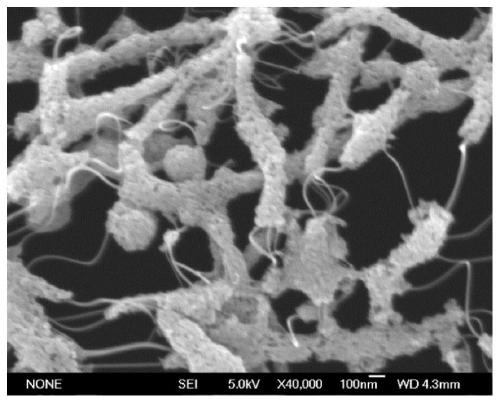

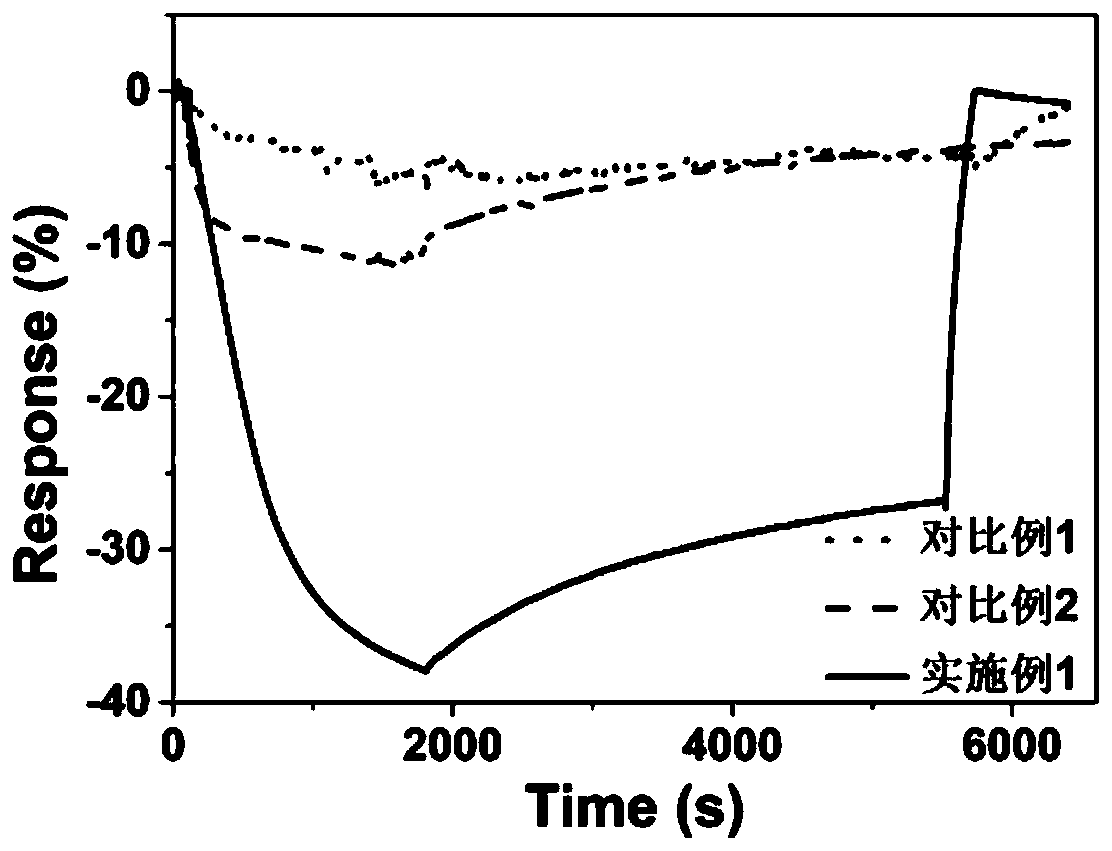

[0041] The single-walled carbon nanotube film was prepared by chemical vapor deposition, and the film was flattened on the copper ring, put into the mixed solution of tetrabutyl titanate and ethanol (1:5) and then taken out, and then hydrolyzed in situ in the air , and then washed with ethanol and deionized water in turn, and calcined in a tube furnace at 500°C for 180 minutes under an argon atmosphere, and assembled the obtained thin film into a device and put it into CGS-TP1 for testing. After the resistance was stable, inject 20ppm NO The gas is maintained (about 1800s), then it is exposed to the air, and after the resistance is stable (about 5500s), it is irradiated with ultraviolet light.

Embodiment 2

[0048] The single-walled carbon nanotube film was prepared by chemical vapor deposition, and the film was flattened on the copper ring, put into the mixed solution of tetrabutyl titanate and ethanol (1:5) and then taken out, and then hydrolyzed in situ in the air , and then washed with ethanol and deionized water in turn, and calcined in a tube furnace at 500 ° C for 180 min in an argon atmosphere, and assembled the obtained film into a device and put it into a CGS-TP1 for testing. After the resistance was stable (about 600 s), open The gas of 50ppm NO was kept (about 1800s), and then it was exposed to ultraviolet light in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com