Method for improving binding force of plating layer of neodymium-iron-boron magnet and neodymium-iron-boron magnet electroplating piece

A neodymium iron boron and bonding force technology, which is applied in the manufacture of electrical components, circuits, inductors/transformers/magnets, etc., can solve the problems of poor bonding force between the neodymium iron boron magnet and the coating, cumbersome processing methods, and high processing costs. The effect of large contact area and surface tension, reducing production cost and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

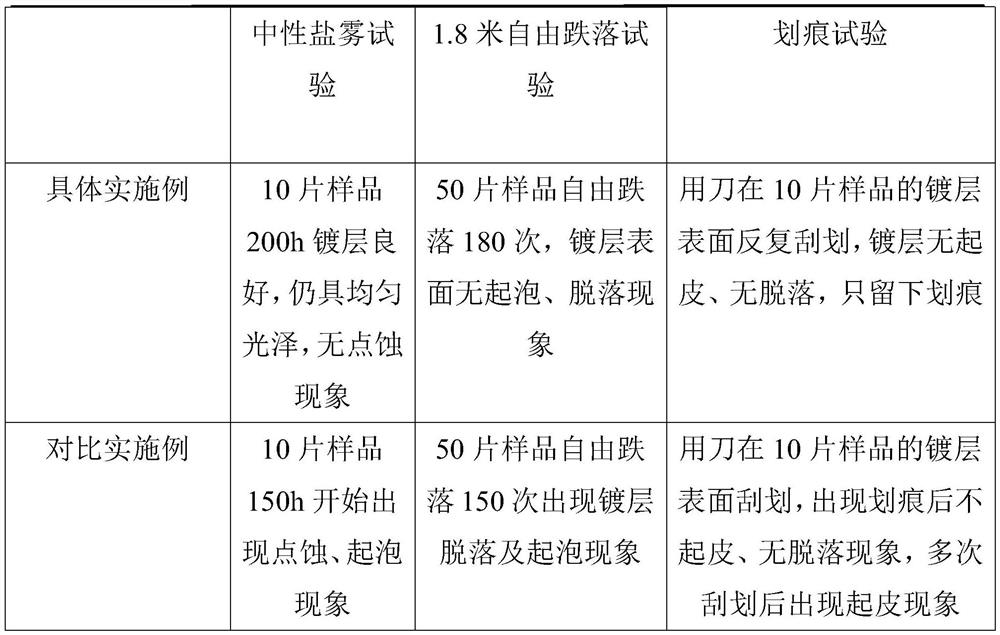

Examples

specific Embodiment

[0041] The present invention will be further described in conjunction with the following specific embodiments, specifically including the following steps:

[0042] (1) Processing: arrange and bond a plurality of semi-finished NdFeB blanks with a size of 50*34*30mm, and slice the bonded semi-finished NdFeB blanks through a multi-wire cutting machine to obtain For semi-finished NdFeB small pieces with a size of 7.8*5*1.2mm, the semi-finished NdFeB small pieces after multi-line cutting are cooked for 20 minutes, washed and dried to remove the residue on the semi-finished NdFeB small pieces.

[0043] (2) Grinding and chamfering: Mix the NdFeB semi-finished product with corundum and silicon carbide, and use a drum chamfering machine or a vibrating finishing machine for grinding and chamfering for 7 hours.

[0044] (3) Degreasing: Ultrasonic degreasing of the semi-finished NdFeB chips after grinding and chamfering. The degreasing liquid is a mixture of sodium carbonate and metal degreasing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com