Graphene modified thermochromic plastic and preparation method and application thereof

A technology of olefin-modified temperature-sensitive and temperature-sensitive color-changing pigments, which is applied in the field of graphene-modified temperature-sensitive color-changing plastics and its preparation, can solve problems such as waste of resources and adverse effects, and achieve the purpose of preventing lifespan reduction, enhancing surface bonding, and color change sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

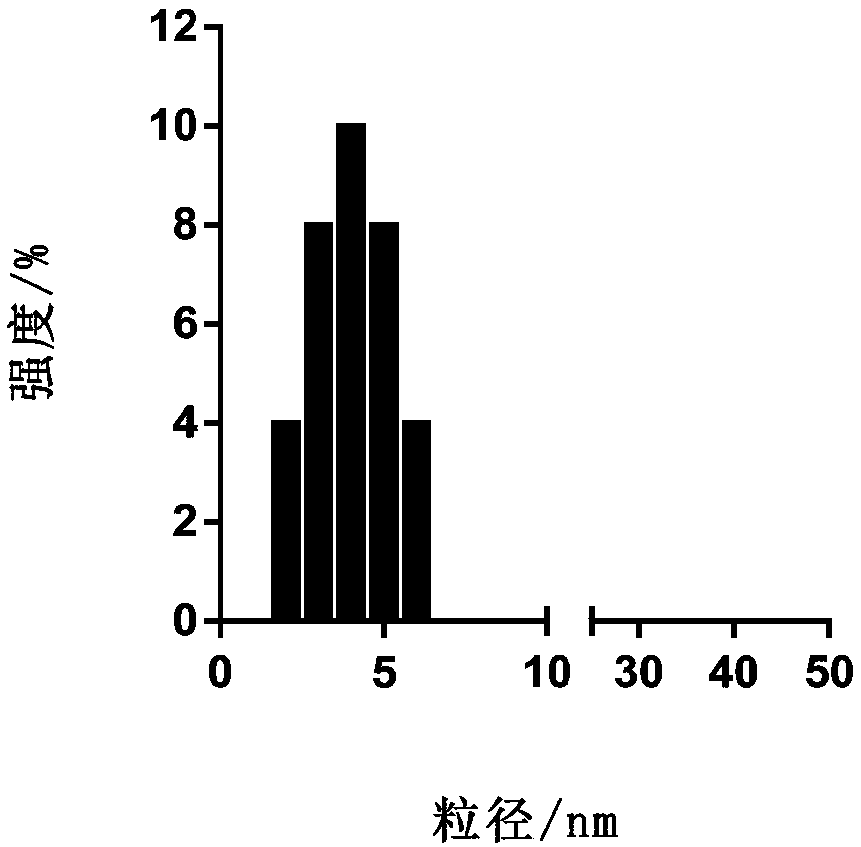

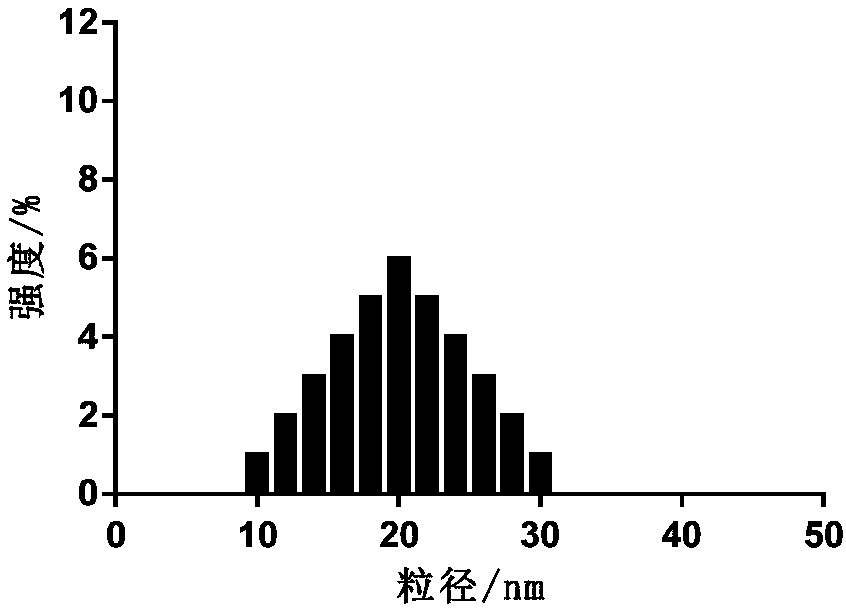

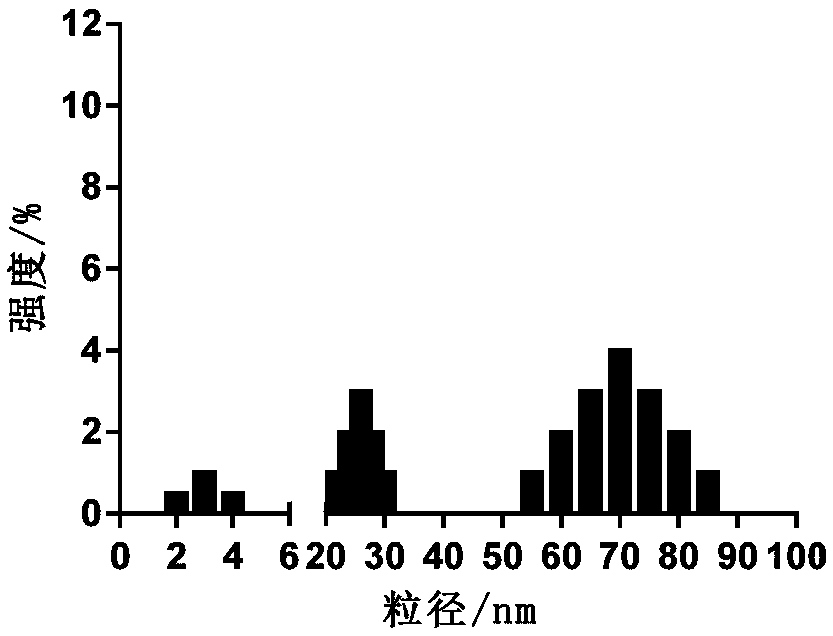

[0045] The preparation of the graphene of embodiment 1 surface treatment

[0046] Take 1 part of graphene oxide and 30 parts of surface treatment agent and put them into a reactor with a spray gun head respectively. The temperature of the reaction chamber is 130 ° C. The graphene oxide and surface treatment agent are sprayed at the same time, and the spray speed is 2m / s, the surface-treated graphene was dry and well dispersed.

[0047] Wherein the surface treatment agent is prepared by mixing 3 parts of γ-mercaptopropyl triethoxysilane, 5 parts of polyethylene glycol 1000, 5 parts of polyacrylic acid and 2 parts of ethylene bis stearic acid amide, and the mass ratio is 1.5:2.5:2.5:1.

Embodiment 2

[0050] Embodiment 2 preferred best surface treatment agent

[0051] Surface treatment agent A: Prepared by uniformly mixing 3 parts of γ-mercaptopropyltriethoxysilane, 7 parts of polyethylene glycol 1000, 8 parts of polyacrylic acid, and 2 parts of ethylene bisstearamide.

[0052] Surface treatment agent B: Prepared by uniformly mixing 2 parts of γ-mercaptopropyltriethoxysilane, 6 parts of polyethylene glycol 1000, 6 parts of polyacrylic acid, and 6 parts of ethylene bisstearamide.

[0053] Surface treatment agent C: 5 parts of γ-mercaptopropyl triethoxysilane, 5 parts of polyethylene glycol 1000, 6 parts of polyacrylic acid, 2 parts of ethylene bis stearic acid amide, 2 parts of pentaerythritol stearate and mix evenly Prepared.

[0054] Surface treatment agent D: 4 parts of γ-mercaptopropyl triethoxysilane, 4 parts of polyethylene glycol 1000, 6 parts of polyacrylic acid, 2 parts of ethylene bis stearic acid amide, 2 parts of pentaerythritol stearate, bis Prepared by unifor...

Embodiment 3

[0059] Example 3 Preparation of graphene-modified thermochromic plastics

[0060] Add 8 parts of 31°C red temperature-sensitive color-changing pigment into 90 parts of polyvinyl chloride, stir for 30 minutes until uniformly dispersed, add 3 parts of surface-treated graphene prepared in Example 1, 0.6 parts of crosslinking agent diethylenetriamine, 0.5 part of triethylenetetramine, 0.4 part of initiator lauryl peroxide, 0.6 part of stabilizer calcium stearate, 0.2 part of plasticizer diisononyl phthalate to make a mixture, and add the mixture to injection molding Injection molding is carried out in the machine, and after the mold is trimmed, it is made into a temperature-sensitive color-changing plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com