Surface treatment method for titanium alloy ingot blank

A treatment method and surface treatment technology, applied in jewelry and other directions, can solve the problems of reducing product yield and increasing production cost, and achieve the effect of eliminating internal stress, enhancing surface bonding force and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

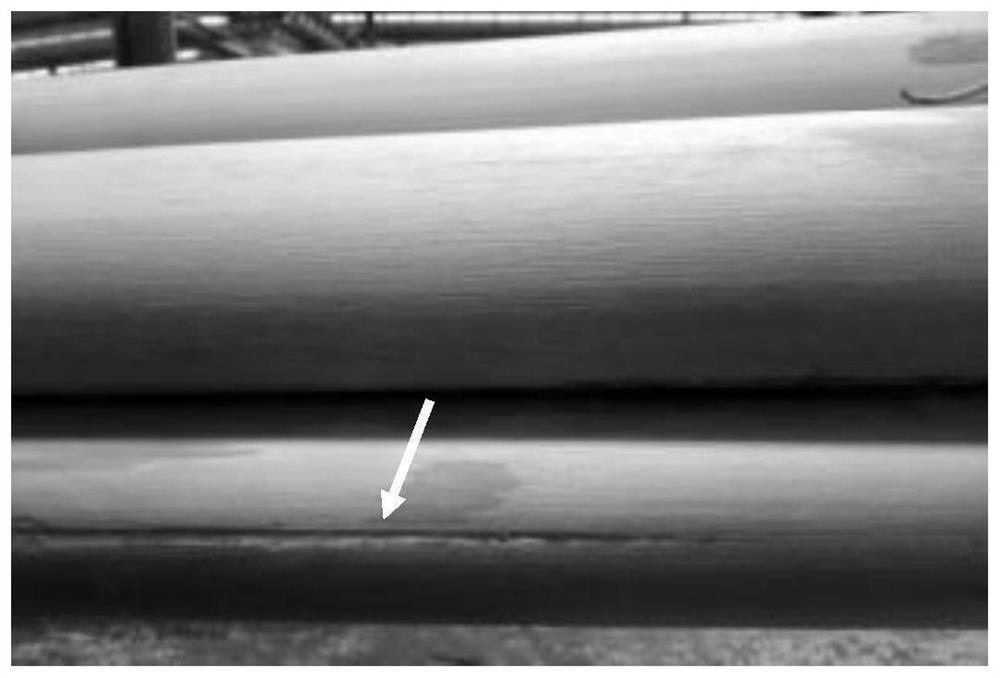

[0035] The present invention also provides a method for preparing a titanium alloy tube blank. The titanium alloy tube blank is obtained by hot extrusion of the metal double-coated titanium alloy ingot described in the above technical solution.

[0036] In the present invention, the hot extrusion method is preferably as follows: the ingot is heated and kept warm first, and then the ingot is extruded. , more preferably 870-930°C, and the heating and heat preservation time is preferably 120-250 min, more preferably 150-210 min. In a specific embodiment of the present invention, the ingot is preferably placed in a box-type resistance furnace for heating and heat preservation, and after the heat preservation is completed, the heat preservation ingot is taken out and extruded; the extrusion is preferably performed by using a 2000T extruder. .

[0037] In the present invention, after the hot extrusion, the method further includes: straightening and pickling the ingot after the hot ...

Embodiment 1

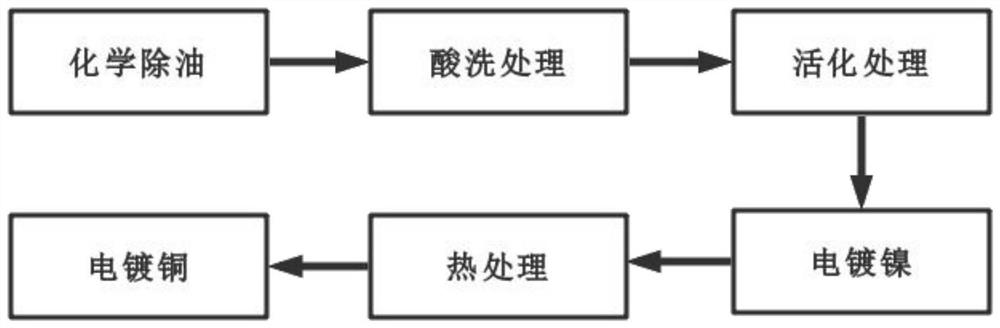

[0041] Surface treatment of TC4 titanium alloy ingot for extrusion and preparation of tube blank, the steps are:

[0042] Step 1: Chemically remove oil from the TC4 titanium alloy extrusion ingot with a size of Φ215×Φ50×500mm. The degreasing solution used for chemical degreasing is composed of sodium hydroxide, sodium carbonate, sodium phosphate and water. Among them, hydrogen The concentration of sodium oxide is 60g / L, the concentration of sodium carbonate is 30g / L, the concentration of sodium phosphate is 45g / L, the degreasing temperature is 50℃, and the degreasing time is 30min.

[0043] Step 2: pickling the TC4 titanium alloy ingot for extrusion after degreasing, the volume ratio of hydrofluoric acid, nitric acid and water in the pickling solution used is 1:2:5, and the acid treatment is carried out at room temperature for 20s .

[0044] Step 3: Activating the ingot for extrusion of TC4 titanium alloy after pickling, the activation solution used in the activation treatmen...

Embodiment 2

[0061] Surface treatment and preparation of billet for TC19 titanium alloy extrusion, the steps are:

[0062] Step 1: Chemically remove oil from the TC19 titanium alloy extrusion ingot with a size of Φ180×Φ60×430mm. The oil removal solution used for chemical oil removal is composed of sodium hydroxide, sodium carbonate, sodium phosphate and water. Among them, hydrogen The concentration of sodium oxide is 50g / L, the concentration of sodium carbonate is 40g / L, the concentration of sodium phosphate is 50g / L, the degreasing temperature is 60°C, and the degreasing time is 20min.

[0063] Step 2: pickling the TC19 titanium alloy ingot for extrusion after degreasing, the volume ratio of hydrofluoric acid, nitric acid and water in the pickling solution used is 1:2:5, and the acid treatment is carried out at room temperature for 15s .

[0064] Step 3: The ingot for extrusion of TC19 titanium alloy after pickling is subjected to activation treatment, and the activation solution used in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com