Self-moving robot, synchronous belt and preparation method of synchronous belt

A robot, self-moving technology, applied in the field of robots, can solve the problems of poor friction performance, difficult to meet the driving and working requirements of new self-moving robots, and the adhesion between the inner ring and the outer ring is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

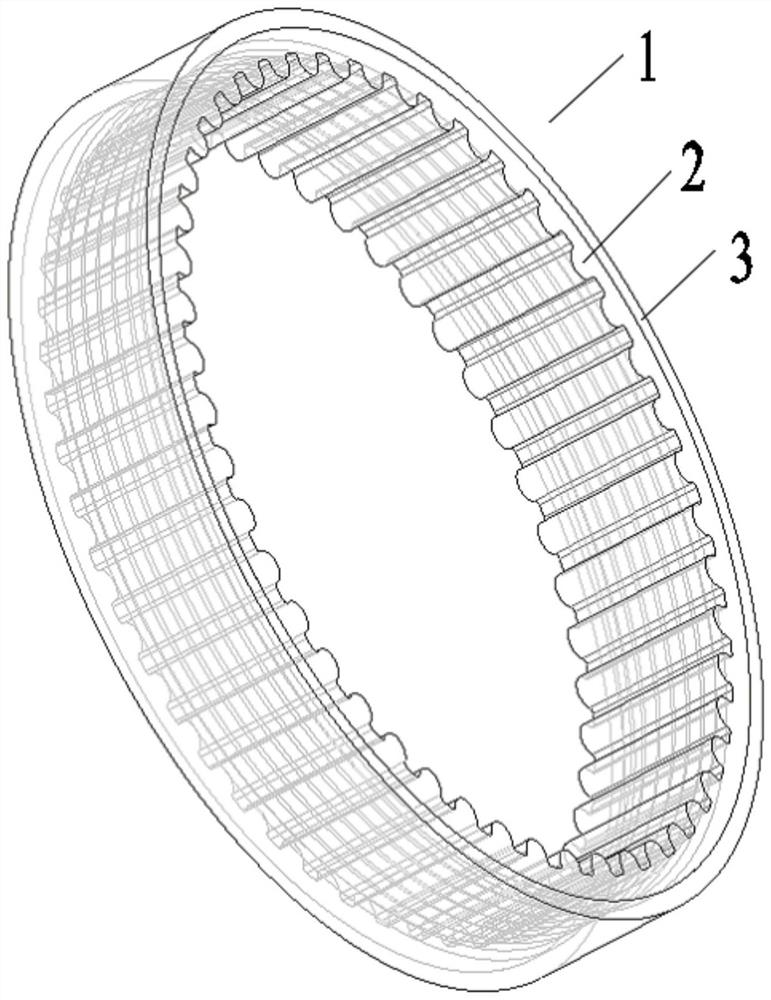

[0055] This embodiment discloses a self-moving robot, which includes a body, and a synchronous belt 1 is arranged at the bottom of the body. The synchronous belt 1 includes an inner ring 2 and an outer ring 3, and the outer ring 3 is in rolling contact with the walking surface. Both the inner ring 2 and the outer ring 3 are made of mixing type polyurethane, the Shore hardness of the inner ring 2 is 60A-90A, the Shore hardness of the outer ring 3 is 30A-60A, and the synchronous A structure with 1 such as figure 1 shown.

[0056]Among them, the mixing type polyurethane is a linear polymer with a low molecular weight (about 20,000-30,000) composed of polyester soft segments and urethane rigid segments, which can be modified and prepared by mixing. Elastomers with desired properties.

[0057] As shown in Table 1, this embodiment tests the hardness, tear strength, abrasion, tensile strength, and elongation at break of mixing type polyurethane and castable polyurethane, and the te...

Embodiment 2

[0094] This embodiment discloses a self-moving robot, which includes a body, a synchronous belt 1 is provided at the bottom of the body, and the synchronous belt 1 includes an inner ring 2 and an outer ring 3, and the inner ring 2 and the outer ring 3 are both Made of mixing polyurethane, the Shore hardness of the inner ring 2 is greater than or equal to the Shore hardness of the outer ring 3, and the structure of the synchronous belt is as follows figure 1 shown.

[0095] Wherein, in the self-moving robot described in this embodiment, the Shore hardness of the inner ring 2 of the synchronous belt 1 is greater than or equal to the Shore hardness of the outer ring 3, and the inner ring 2 can provide sufficient supporting force for the outer ring 3 to strengthen the inner ring. The bonding force between the ring 2 and the outer ring 3 improves the stability of the synchronous belt 1, thereby improving the pressure resistance and stability of the self-mobile robot. The Shore har...

Embodiment 3

[0108] Such as Figure 1-Figure 4 As shown, this embodiment discloses a synchronous belt 1, including an inner ring 2 and an outer ring 3, wherein the inner ring 2 and the outer ring 3 are both made of mixing type polyurethane, and the inner ring 2 The Shore hardness of the outer ring 3 is 60A-90A, and the Shore hardness of the outer ring 3 is 30A-60A.

[0109] Further, the outer surface of the inner ring 2 and / or the inner surface of the outer ring 3 are coated with adhesive, and the inner ring 2 and the outer ring 3 are bonded by the adhesive.

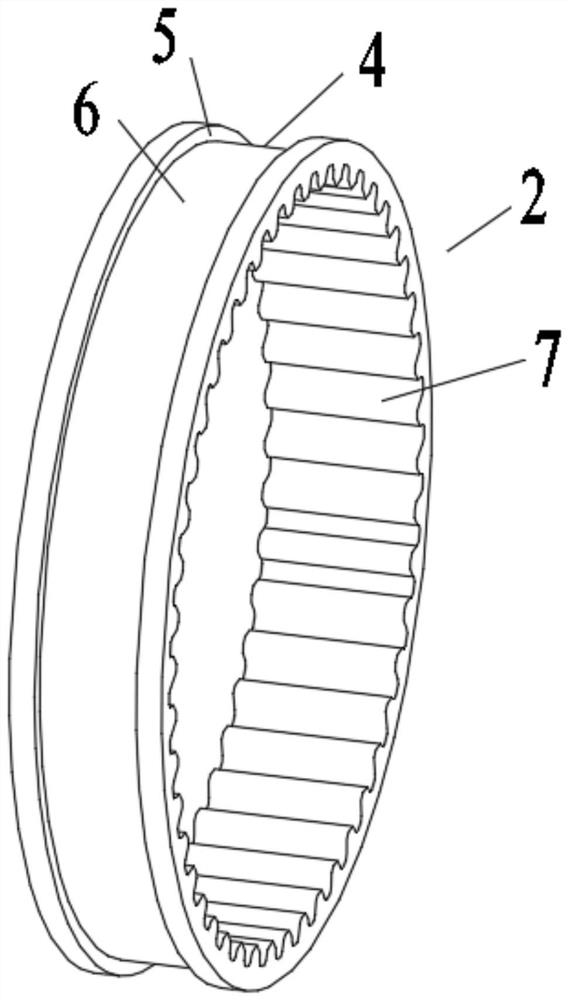

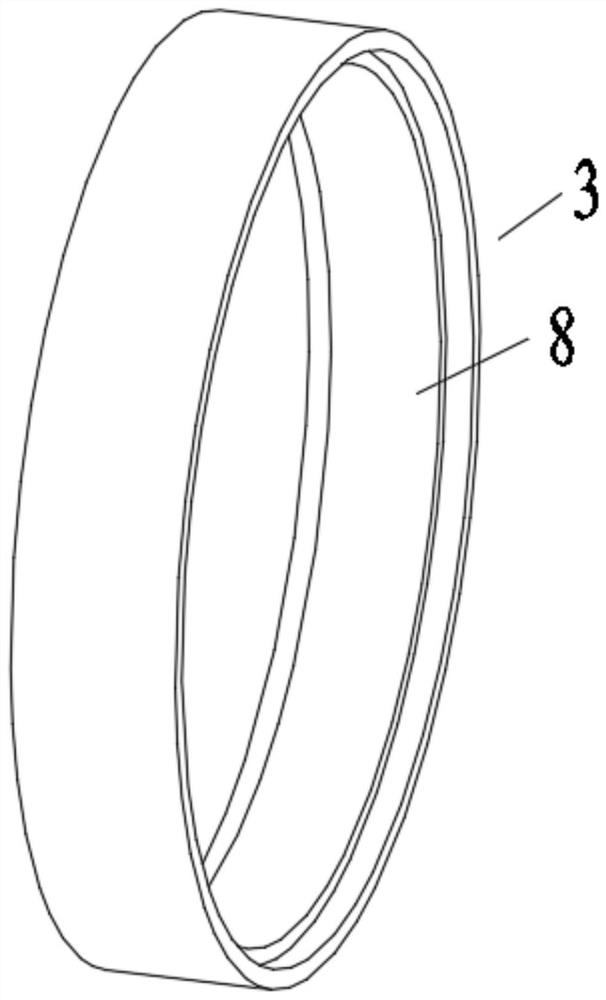

[0110] Further, the inner ring 2 is provided with a groove 4, and the outer ring 3 is provided with a protrusion 8 adapted to the groove 4, and the inner ring 2 and the outer ring 3 pass through the groove 4 is connected with said protrusion 8 .

[0111] Further, the groove 4 is an open groove, a closed groove or a straight groove.

[0112] Further, the groove 4 of the inner ring 2 includes a groove bottom 6 and a groove wall 5, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com