Patents

Literature

79results about How to "Reduce dielectric loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

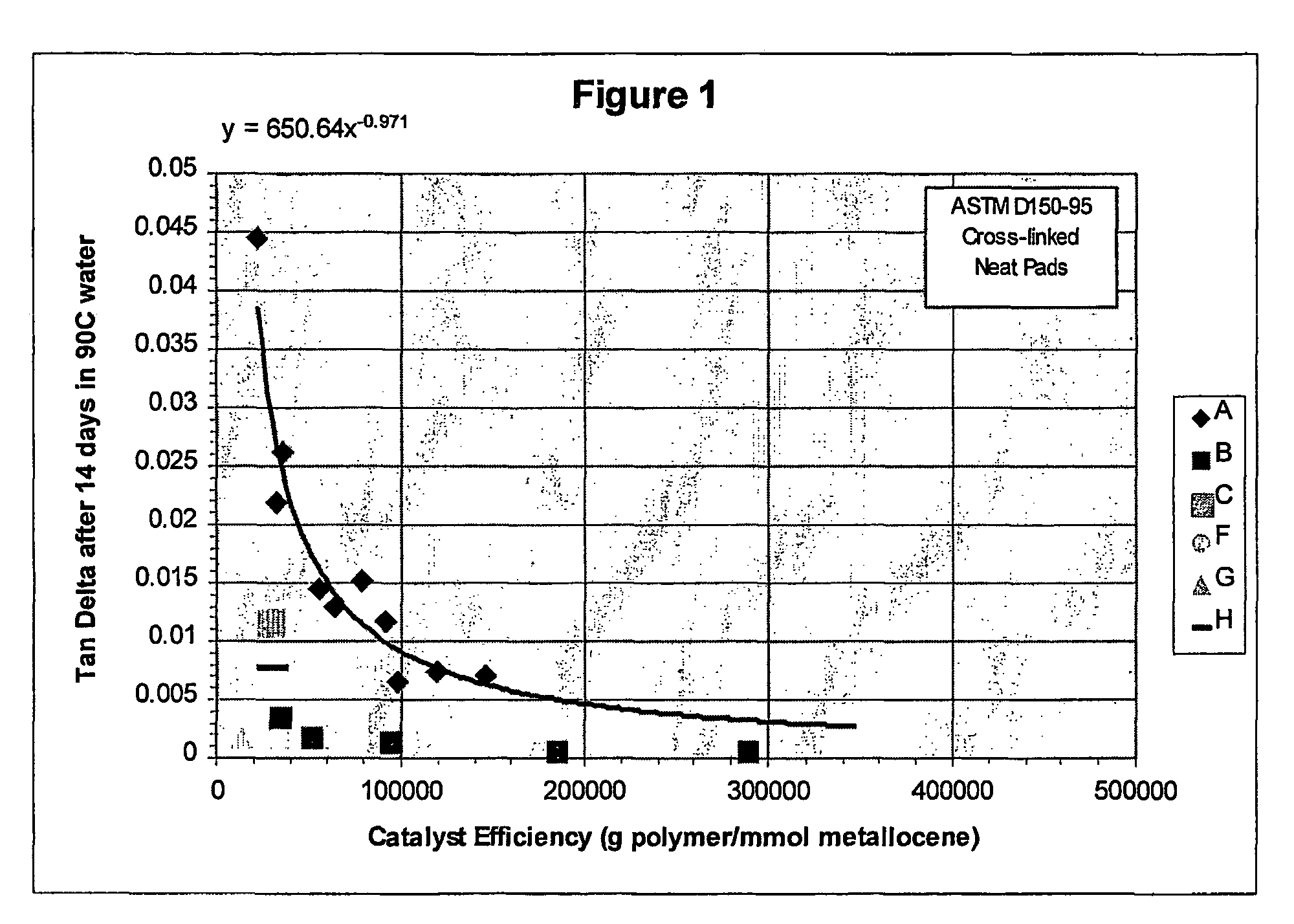

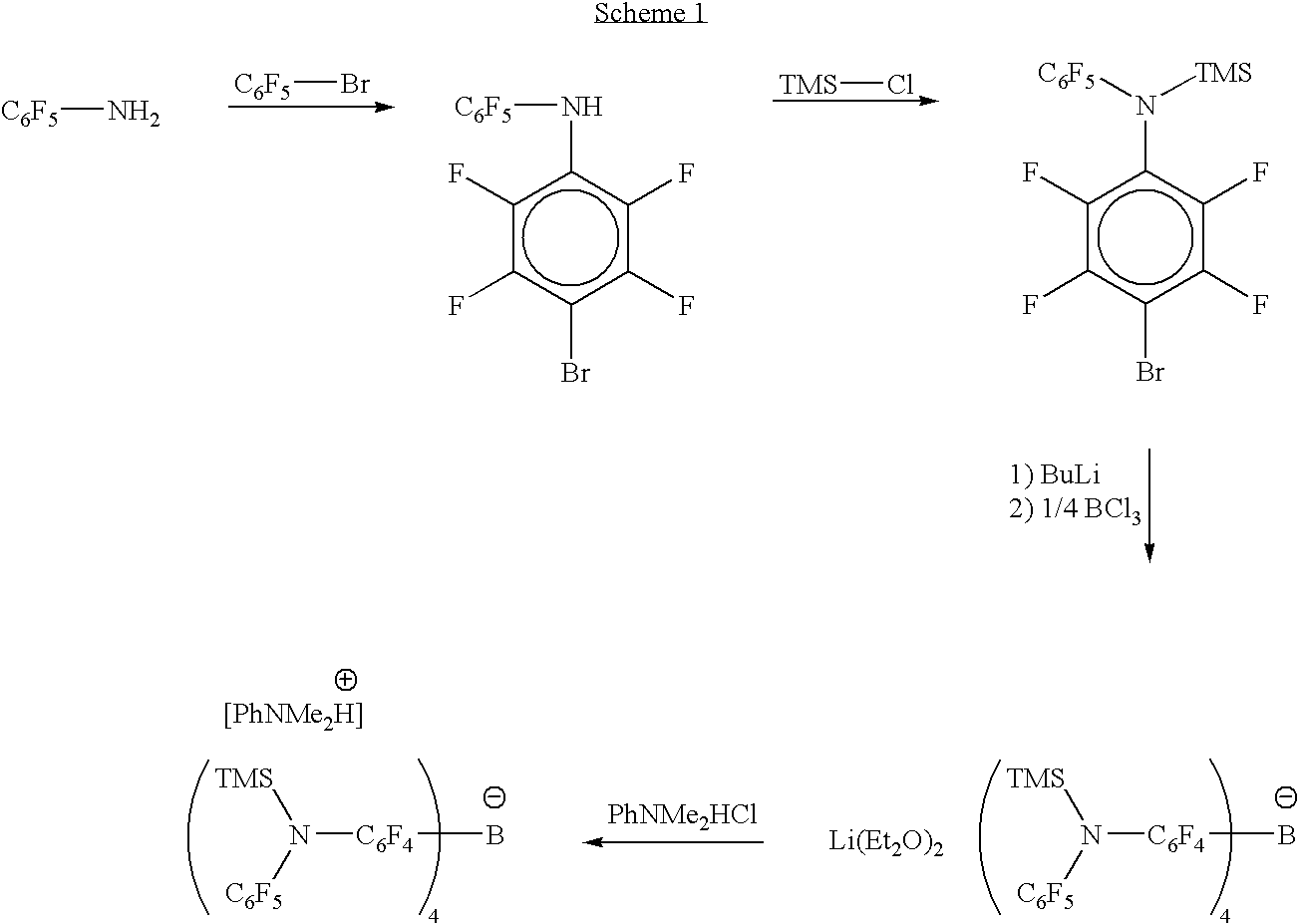

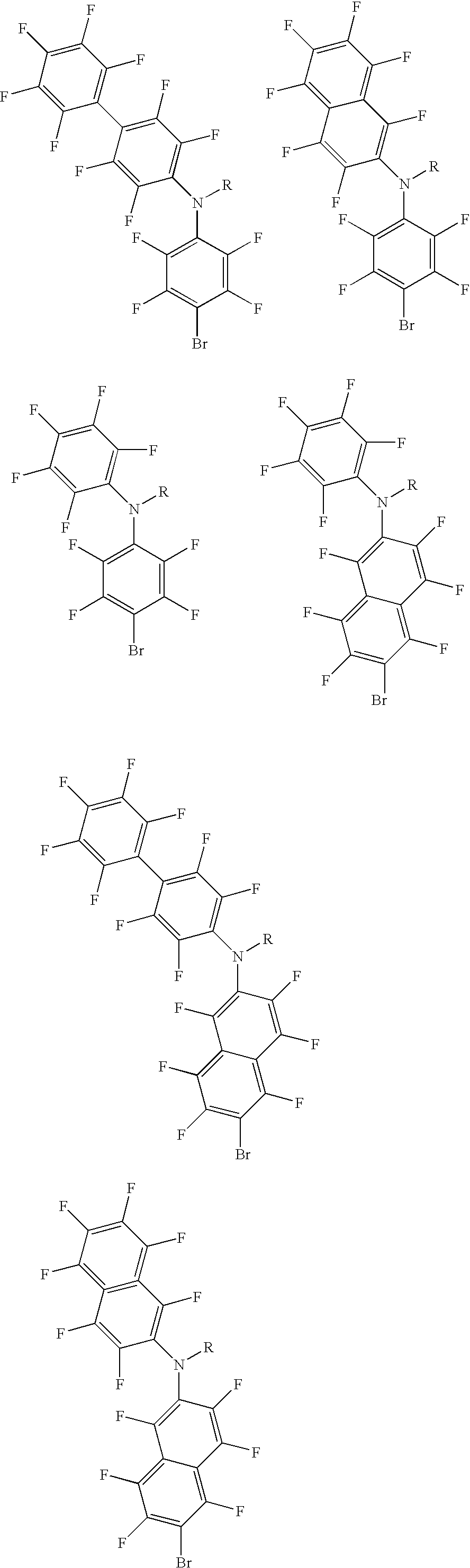

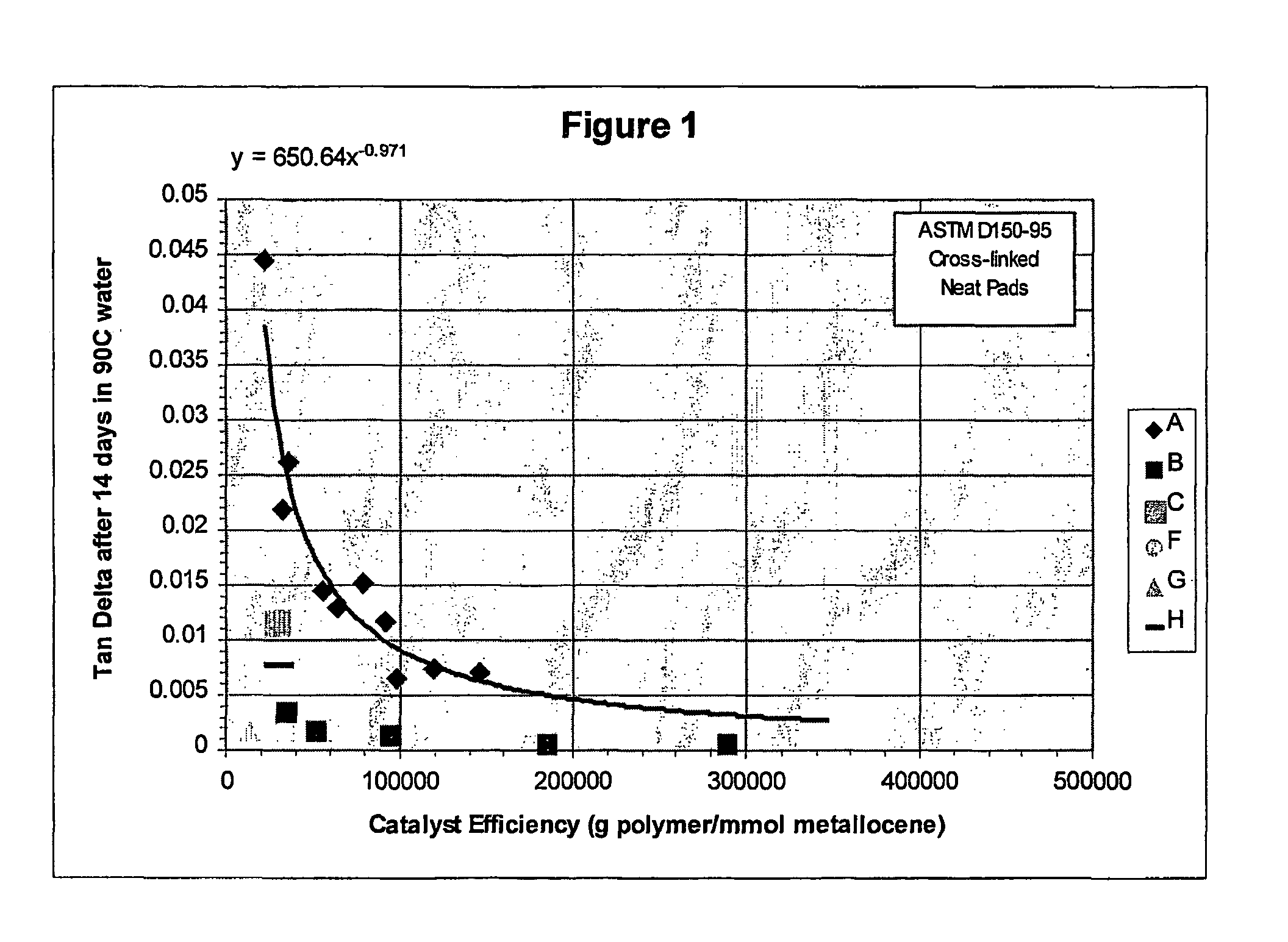

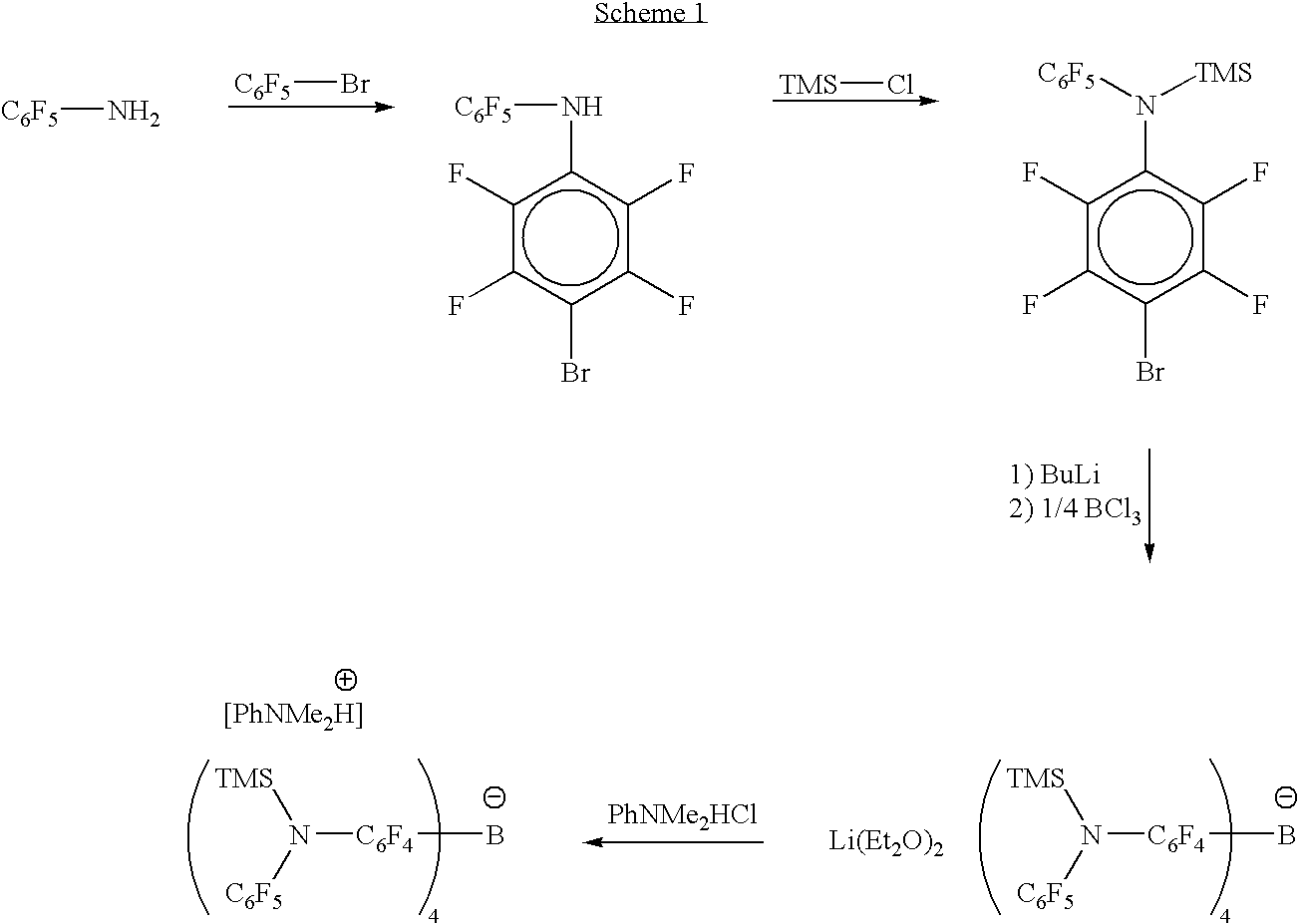

Polyolefins made by catalyst comprising a noncoordinating anion and articles comprising them

ActiveUS7511104B2Low mobilityReduce dielectric lossOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsPolymer sciencePolyolefin

Polymers made by transition metal catalyst systems comprising a bulky noncoordinating anion (NCA) as cocatalyst component. In comparison to polymers containing a conventional NCA, these polymers show a considerably lower dielectric loss, making them suitable for insulation applications such as for power cable.

Owner:EXXONMOBIL CHEM PAT INC

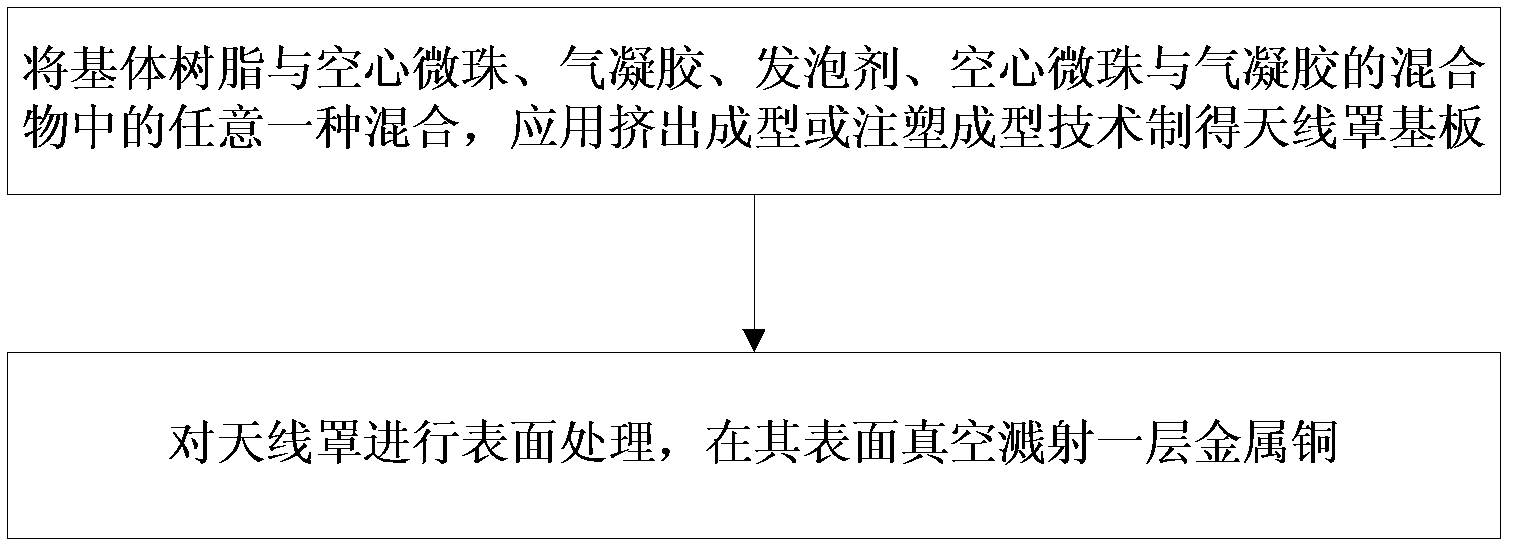

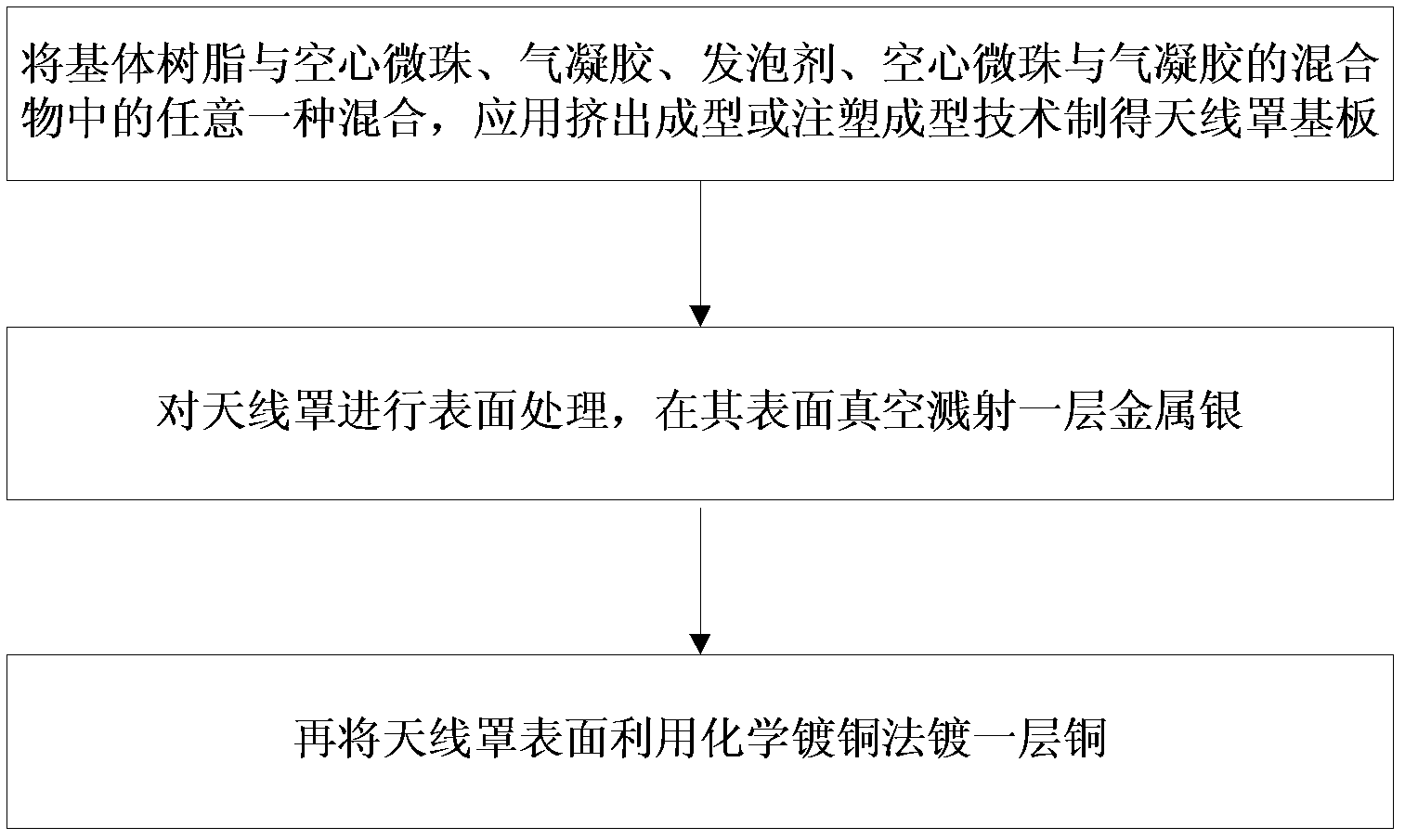

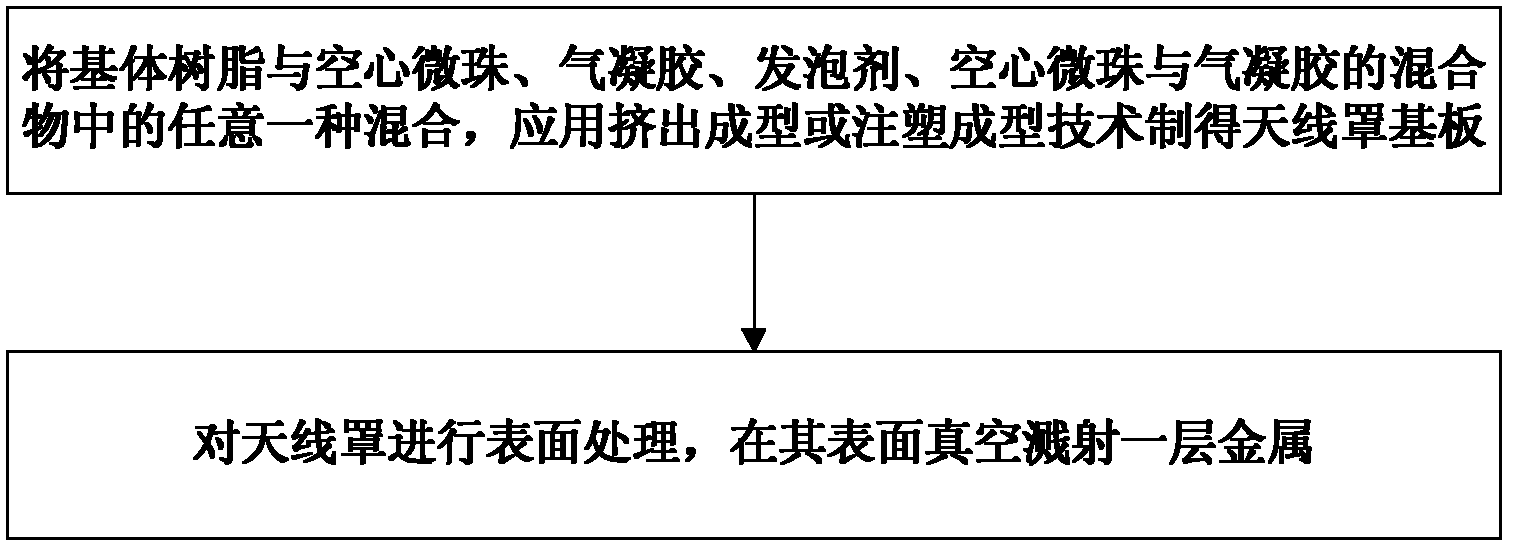

Antenna housing substrate and preparation method thereof

InactiveCN102604187ALow dielectric constantReduce dielectric lossRadiating element housingsGlass fiberFoaming agent

The invention provides an antenna housing substrate and a preparation method thereof. The antenna housing substrate is prepared by mixing substrate resin with any one of hollow microspheres, aerogel, a foaming agent and mixture of the hollow microspheres and the aerogel and applying an extrusion forming or injection molding technology. The antenna housing substrate prepared by the method is provided with no glass fiber reinforcing layer, so that the dielectric loss is low, the dielectric constant is low; meanwhile, substrates of different performances can be prepared through design of the formula; the industrial production requirements are met; and the antenna housing substrate has good development and application prospect.

Owner:KUANG CHI INNOVATIVE TECH

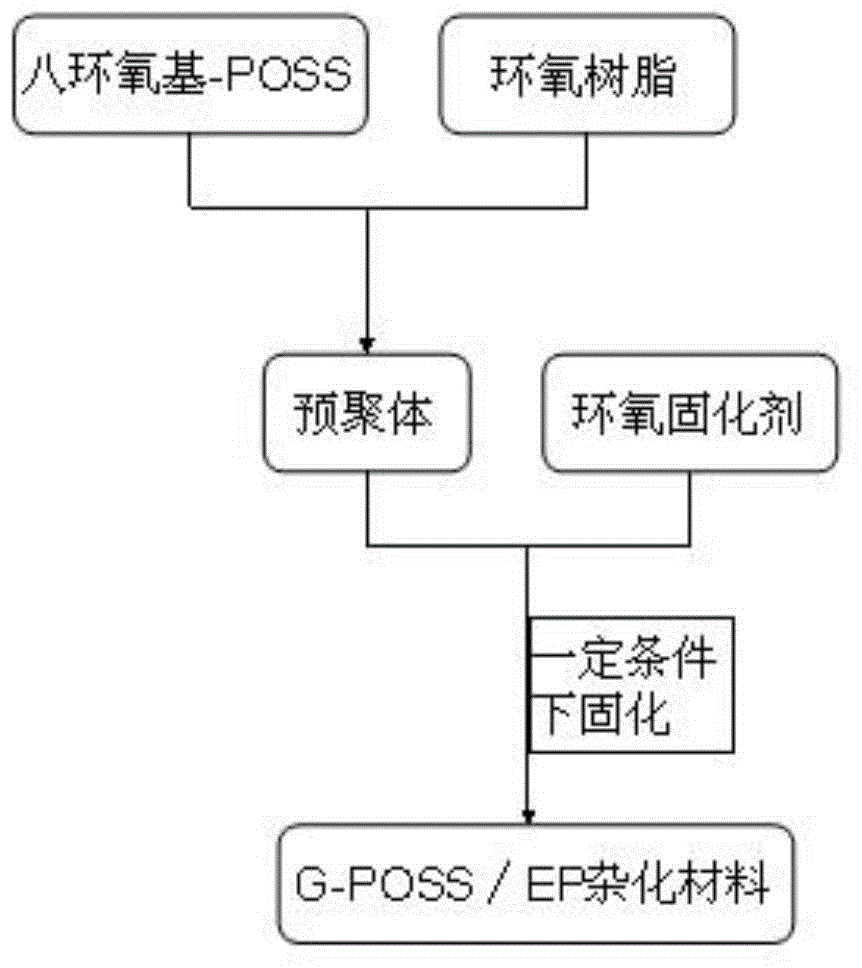

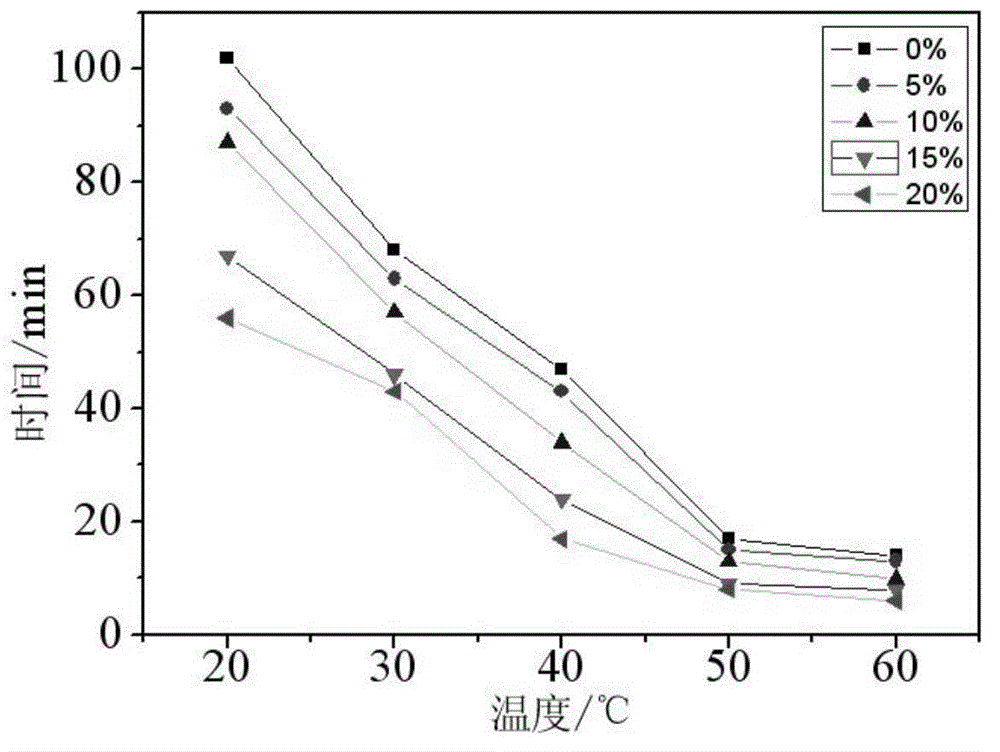

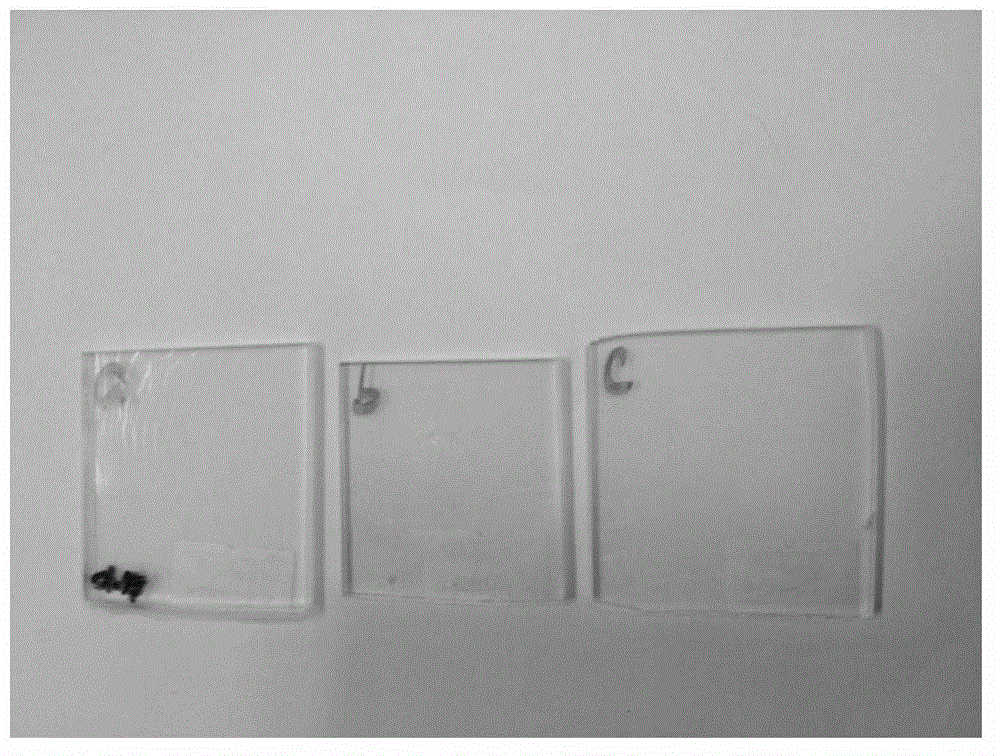

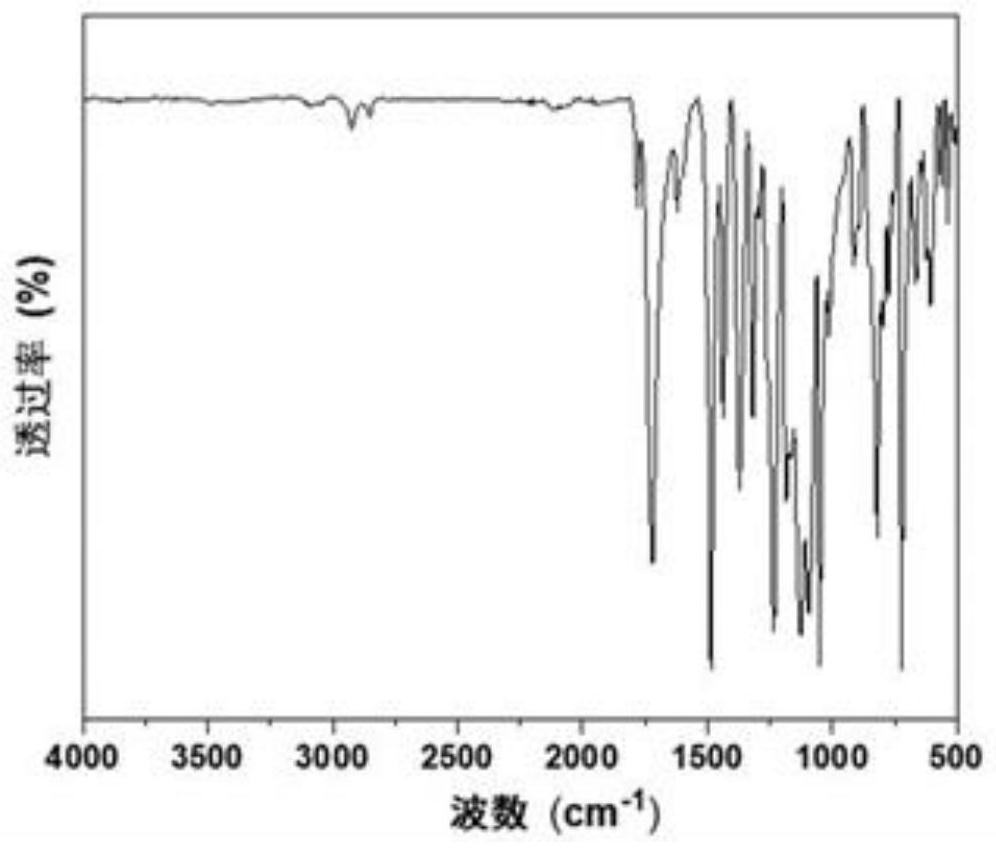

Low dielectric constant polyhedral oligomeric silsesquioxane (POSS)/ epoxy resin hybrid material and preparation method

The invention relates to a low dielectric constant polyhedral oligomeric silsesquioxane (POSS) / epoxy resin hybrid material and a preparation method. Epoxy resin and eight epoxy group polyhedral oligomeric silsesquioxane (G-POSS) are evenly mixed in a 80 DEG C breaker according to a certain proportion, an equivalent amount of curing agent triethylene tetramine (TETA) (an amino group in the TETA and an epoxy group in the G-POSS, epoxy resin (EP) are measured according to a 1:1 molar rate) is added and fully stirred, after vacuum defoamation is conducted for 20-30 minutes, the mixture is slowly poured into a preheating mold, conducted solidification in a stove 50 DEG C / 2 hours, 70 DEG C / 3 hours and 80DEG C / 1 hour, cooled to room temperature along with the stove and processed for 4-6 hours after demolding. The low dielectric constant POSS / epoxy resin hybrid material is small in average grain size and excellent in transparent performance, mechanical property and dielectric property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-loss LiZn ferrite material for phase shifter and preparation method thereof

InactiveCN101552072ALow coercivityReduce dielectric lossInorganic material magnetismDielectric lossMagnetization

A low-loss LiZn ferrite material for a phase shifter relates to the technical field of preparation of ferrite materials. The low-loss LiZn ferrite material consists of main materials, additives and binding agents, calculated by Fe2O3, ZnO, Mn3O4 and Li2CO3, the main materials comprise 64-71 mol percent of Fe2O3, 15-22 mol percent of ZnO, 0.8-1.5 mol percent of Mn3O4 and 9.9-12 mol percent of Li2CO3; relative to the main materials, the additives are calculated by Bi2O3, BST and Nb2O5, and the proportion is 0.5-3.0 wt percent of Bi2O3, 0.1-0.5 wt percent of BST and 0.05-0.4 wt percent of Nb2O5. The invention reduces the coercivity and the dielectric loss, and improves the saturation magnetization, thus realizing the low temperature preparation of the LiZn ferrite material with low coercivity, low dielectric loss and high saturation magnetization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

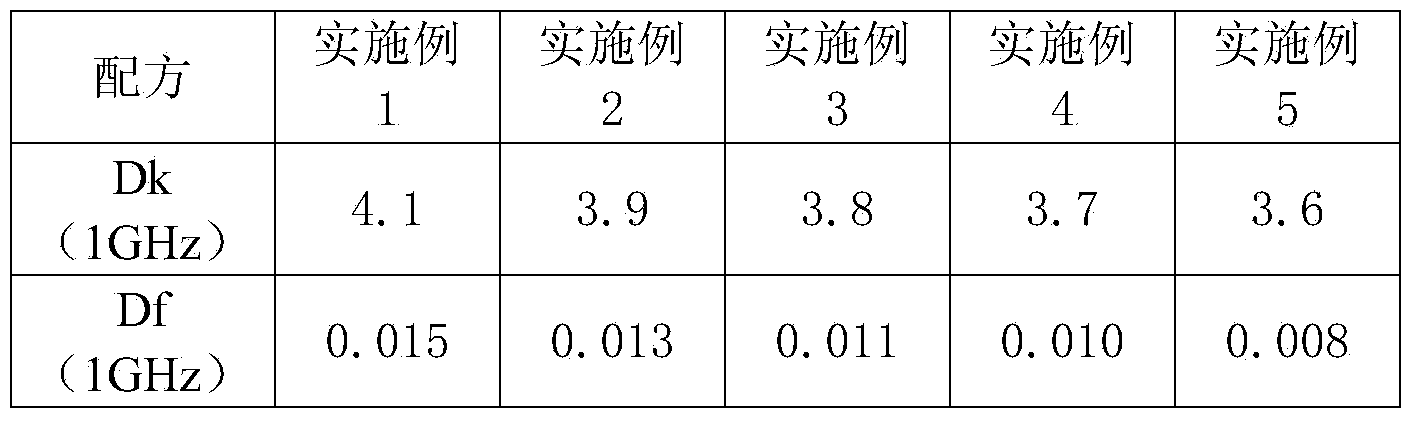

Thermosetting resin composition as well as prepreg and laminated board manufactured by utilizing same

ActiveCN103992621AExcellent dielectric propertiesLow dielectric constantSynthetic resin layered productsMetal layered productsDielectric lossCyanate ester

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following components in parts by solid weight: (a) 20-40 parts of active ester resin; (b) 30-50 parts of epoxy resin; (c) 20-60 parts of cyanate ester resin. A laminated board manufactured by adopting the thermosetting resin composition has excellent dielectric property, dielectric constant and dielectric loss are greatly reduced compared with those in the prior art, and the laminated board can show extremely low dielectric constant and low dielectric loss tangent in a high-speed and high-frequency signal transmission process. The thermosetting resin composition has an obvious effect and positive practical significance.

Owner:SHENGYI TECH SUZHOU

Prepreg and metal foil substrate

InactiveCN102039701ALow hygroscopicityLow dielectric lossLamination ancillary operationsSynthetic resin layered productsGlass fiberMetal foil

The invention relates to a prepreg which is manufactured from heat-proof nonflammable thermosetting resin and glass fiber cloth, wherein the thermosetting resin comprises epoxy resin, an aromatic ester hardener and a fire-retardant compound. The invention also relates to a metal foil substrate which is formed by pressing the prepreg and a metal foil laminated plate. In addition, the prepreg and the metal foil substrate have preferred dielectric property, high heat resistance and fire resistance and lower hygroscopicity.

Owner:ELITE MATERIAL

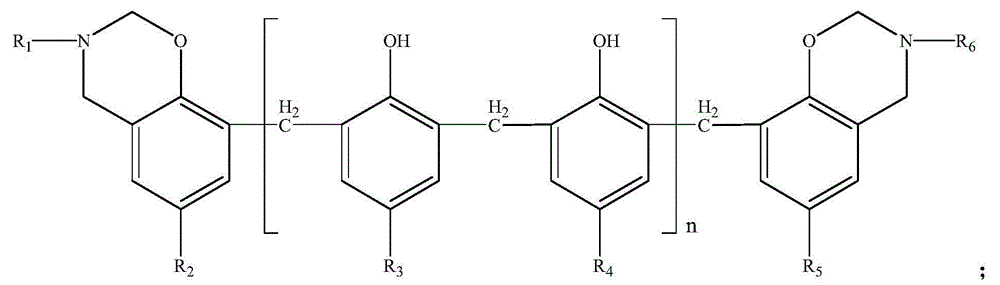

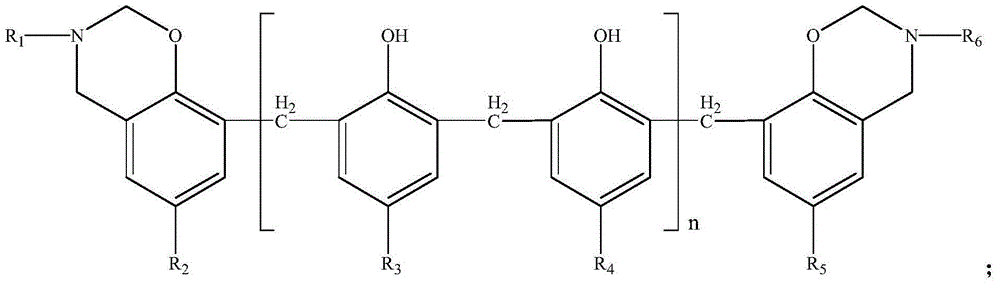

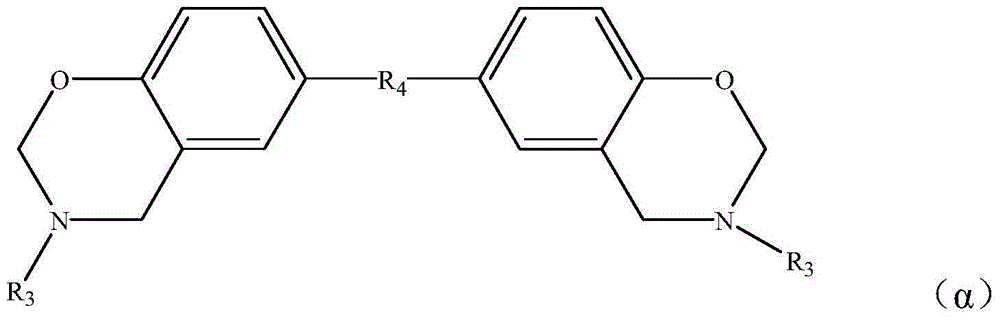

Halogen-free resin composition, and prepreg and laminated boards which are prepared from halogen-free resin composition

ActiveCN104804377ASolve the problem of poor resilienceImprove machinabilitySynthetic resin layered productsCircuit susbtrate materialsEpoxyPolyresin

The invention relates to a halogen-free resin composition, and a prepreg and laminated boards which are prepared from the halogen-free resin composition. The halogen-free resin composition comprises following ingredients, by weight, 5 to 45 parts of epoxy resin, 10 to 80 parts of benzoxazine resin, 0.5 to 25 parts of a curing agent, and 1 to 15 parts of a fire retardant. The invention also provides the prepreg, the laminated boards, and printed circuit-used the laminated boards which are prepared from the halogen-free resin composition. According to a preparation method, two kinds of benzoxazine resins are combined at a certain ratio, so that excellent heat and humidity resistance of the halogen-free resin composition is ensured, and resin composition roughness is increased effectively; and dielectric properties and machining properties of the prepreg, the laminated boards, and the printed circuit-used the laminated boards are excellent.

Owner:GUANGDONG SHENGYI SCI TECH

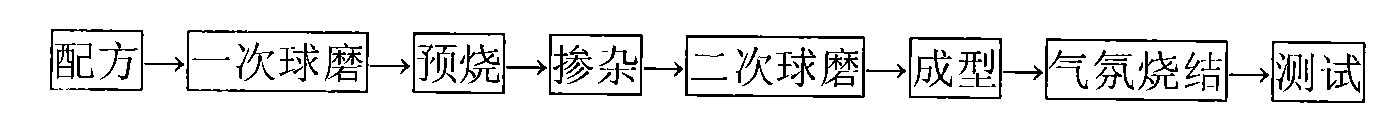

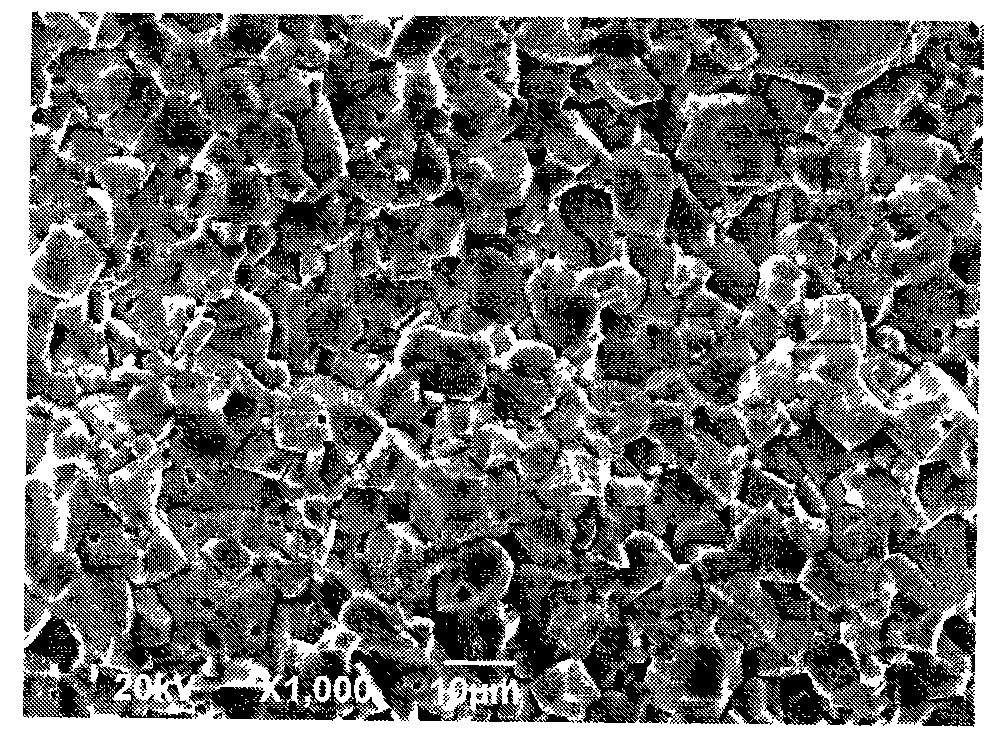

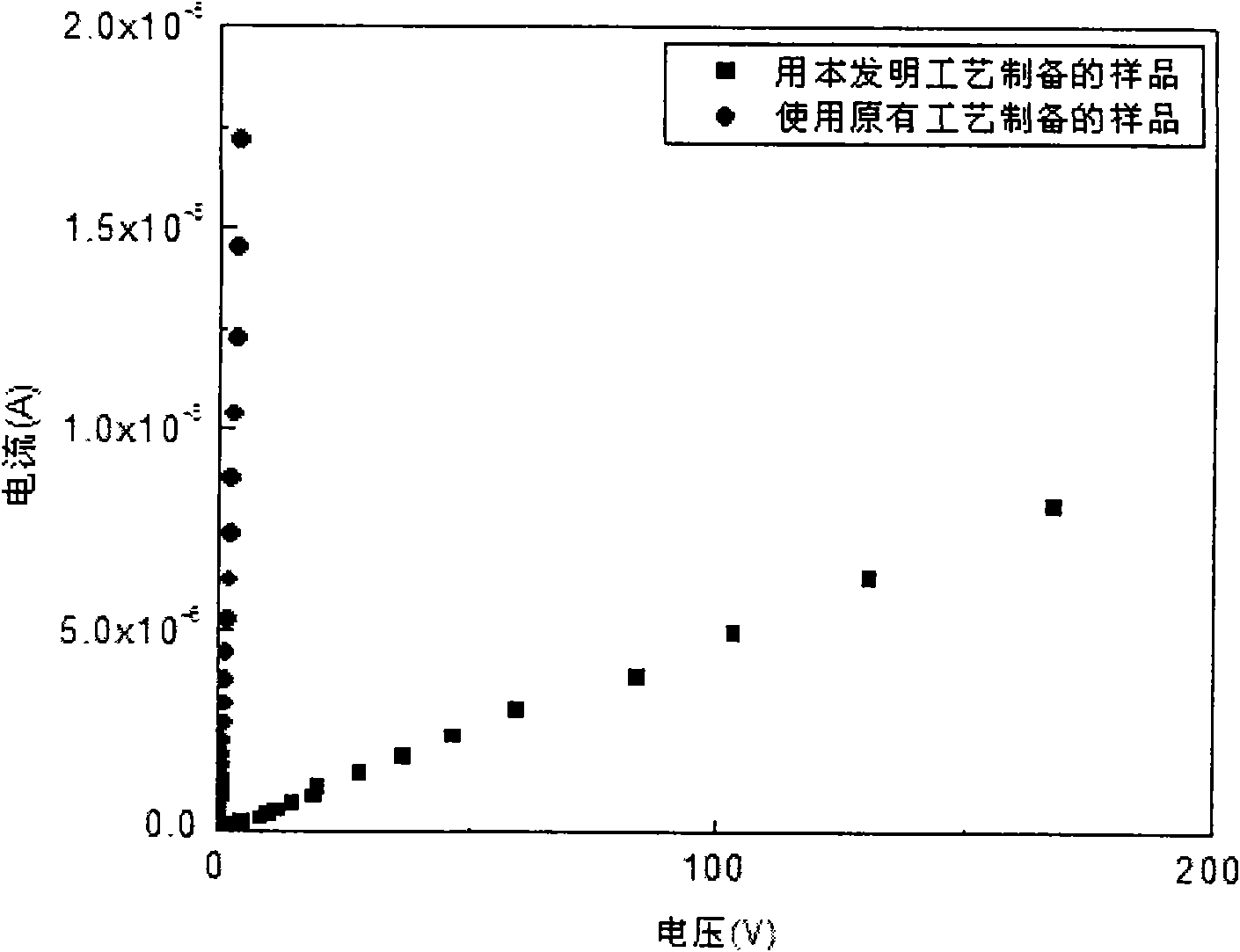

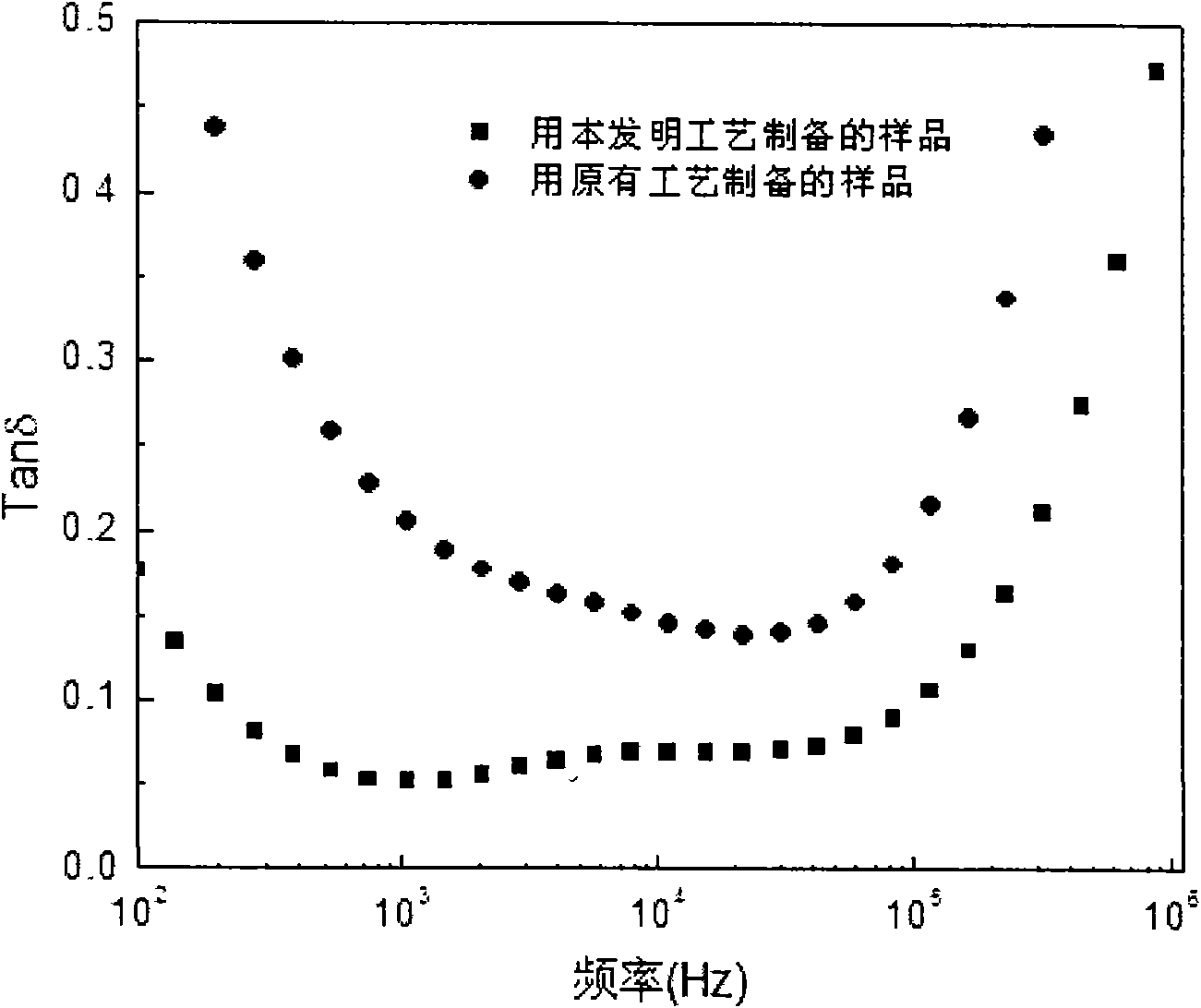

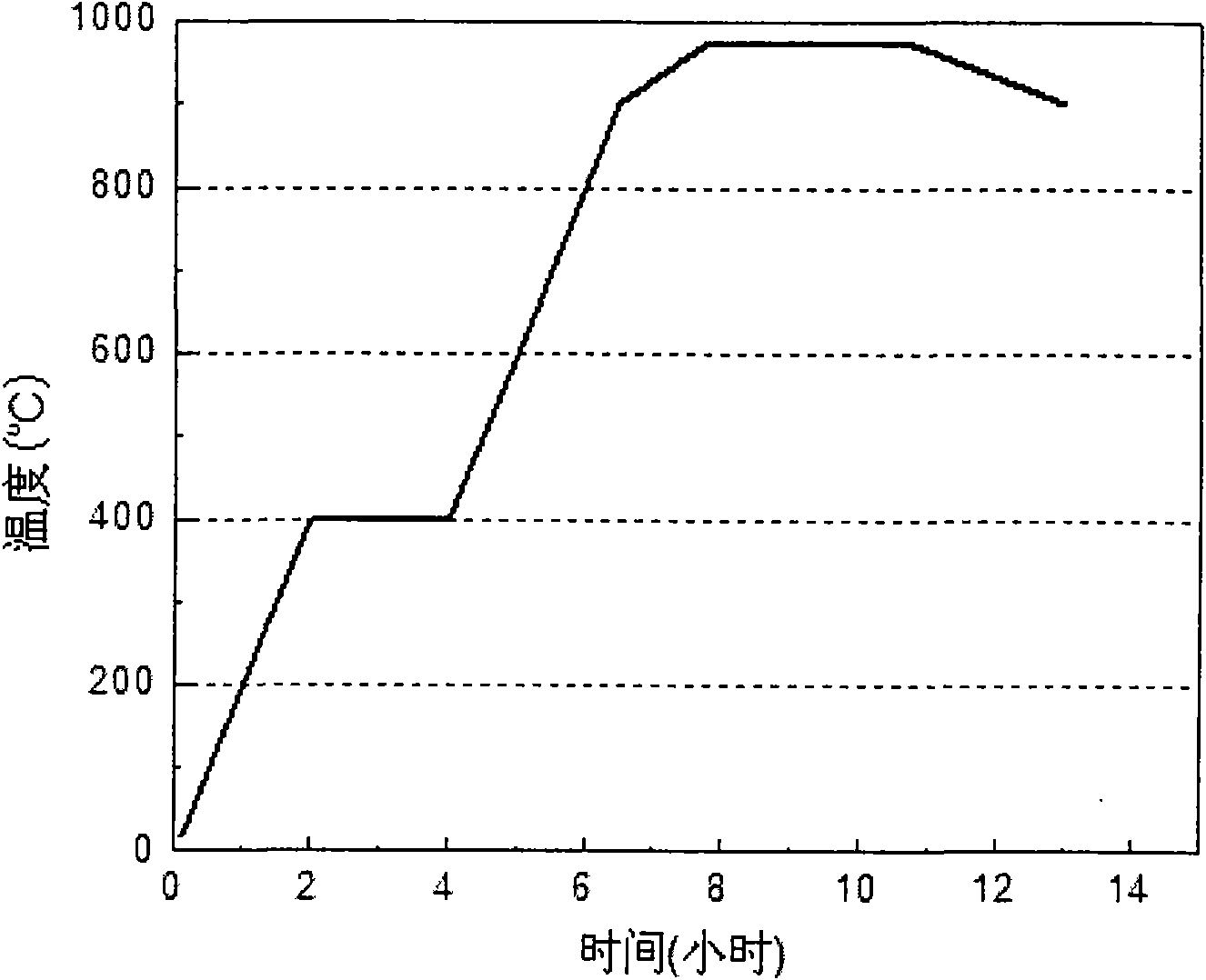

Method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics

ActiveCN101671174ASolve the problem of too much conductivitySuitable for industrial applicationsCeramic sinteringChemical reaction

The invention relates to a method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics, belonging to the technical field of high dielectric ceramic materials. The calcium copper titanate ceramics are prepared from initial raw materials of CaCO3 or CaO, CuO and TiO2, wherein after being mixed, the raw materials are processed by mix grinding and then processed by presintering at the temperature from 800 DEG C to 950 DEG C after mix grinding, hard blocks after presintering are cracked to be ground, and the powdered materials after presintering and grinding are prepared into green bodies with predetermined shapes; and the green bodies are heated to the sintering temperature ranging from 960 DEG C to 990 DEG C from room temperature, and heat preservation is carried out for 1 to 24 hours at the sintering temperature, thereby realizing the sintering densification of the ceramics. The preparation method controls performance parameters by controlling technological parameters, and structural changes and chemical reactions in a sintering process. The ceramic materials prepared by the method can meet the requirement on industrial application; and simultaneously, compared with the prior art, the preparation method can obviously reduce the energy consumption, is environment-friendly and reduces the production cost.

Owner:TSINGHUA UNIV

Low-dielectric POSS type epoxy resin composite and preparation method thereof

The invention provides a low-dielectric POSS type epoxy resin composite and a preparation method thereof, and relates to the field of high molecular polymer materials. The low-dielectric POSS type epoxy resin composite comprises 100 parts of POSS type epoxy resin, 4-40 parts of a curing agent and 5 parts of additives. The composite disclosed by the invention introduces the additives, such as POSS monomers with low dielectric constants by synthesizing the POSS type epoxy resin and modifying the POSS type epoxy resin, so that the dielectric constant of the composite can be notably reduced, the hydrophilicity of the composite is reduced, the heat stability of the composite is improved, and the low-dielectric POSS type epoxy resin composite is suitable for various fields of electronic packaging and the like. The preparation method of the composite is simple, and convenient and quick to operate, and has excellent development and application prospects.

Owner:BEIJING UNIV OF CHEM TECH

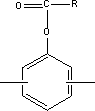

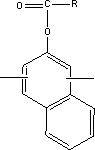

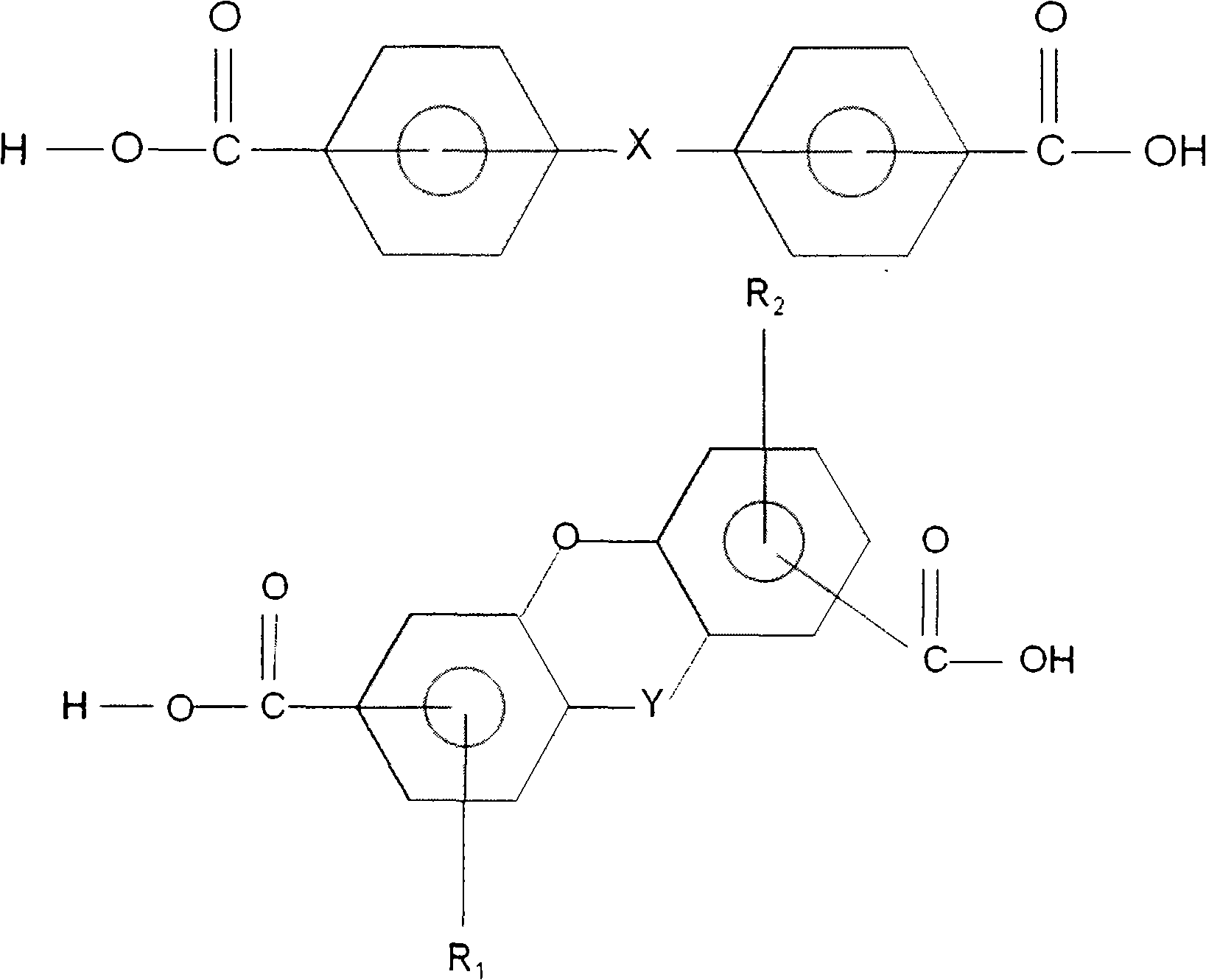

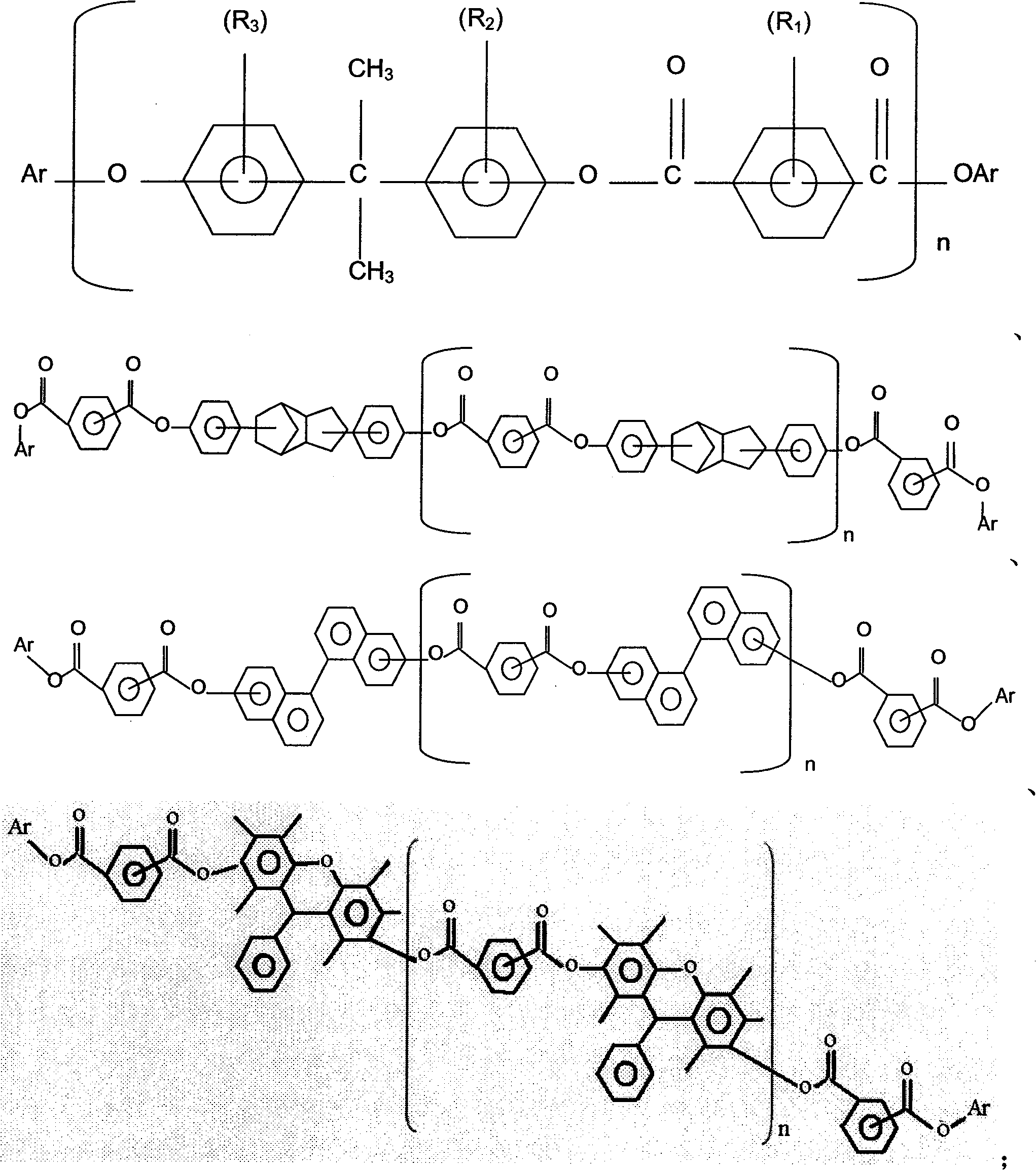

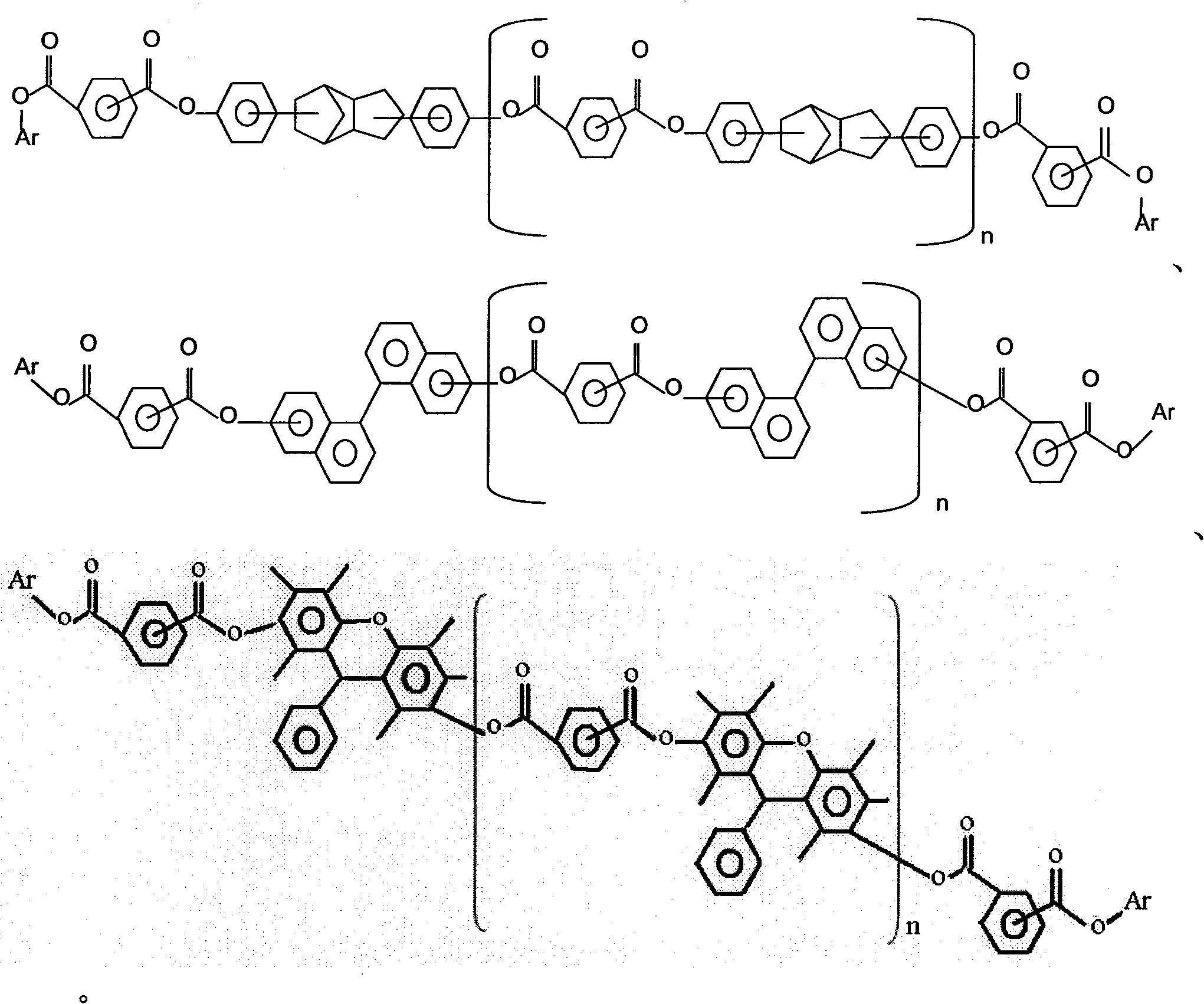

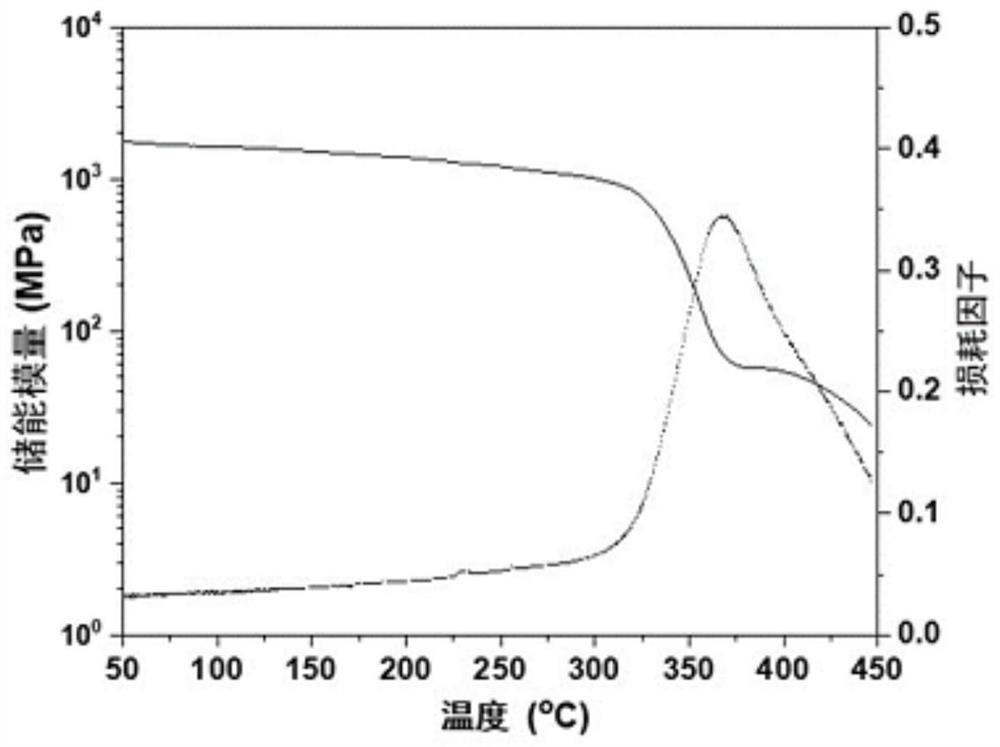

Preparation method of high-performance thermotropic liquid crystal polyarylester

InactiveCN112126205ALow dielectric constantReduce dielectric lossLiquid crystal compositionsBenzoic acidPolymer science

The invention discloses a preparation method of high-performance thermotropic liquid crystal polyarylester, and relates to a preparation method of thermotropic liquid crystal polyarylester with low dielectric constant and high impact strength, which comprises the following steps of: 1, reacting 2, 5-dihydroxy terephthalic acid with p-hydroxybenzoic acid, 2-hydroxy 6-naphthoic acid, p-hydroxybenzoic acid, p-hydroxybenzoic acid and p-hydroxybenzoic acid; adding acetic anhydride, 4-aminopyridine and an antioxidant into a polymerization kettle, and carrying out melt polycondensation to prepare a prepolymer of the thermotropic liquid crystal polyarylester; 2, performing solid-phase polycondensation reaction on the prepolymer in a rotary kiln under the protection of nitrogen to obtain high-molecular-weight polymer powder; 3, mixing the high-molecular-weight polymer powder with polytetrafluoroethylene resin, cooling and drawing to prepare primary polyarylester; and 4, carrying out heat treatment on the primary polyarylester. The dielectric constant of the thermotropic liquid crystal polyarylester is less than 3.0, the dielectric loss is less than 0.003, the impact strength can reach 35-50kJ / m < 2 >, and the thermotropic liquid crystal polyarylester has high dimensional safety and excellent mechanical properties and processability.

Owner:宁波聚嘉新材料科技有限公司 +1

Copper clad laminate

InactiveCN103731980ALow dielectric constantReduce dielectric lossFilm/foil adhesivesEpoxy resin adhesivesElectrical conductorCarbamate

The invention discloses a copper clad laminate. The copper clad laminate comprises two conductor layers and a plurality of insulating medium layers which are arranged between the two conductor layers, wherein the plurality of insulating medium layers comprise at least one layer of modified crosslinking type PTFE (Polytetrafluoroethylene) resin combination bonding sheet, and a modified crosslinking type PTFE resin combination comprises modified crosslinking type PTFE resin containing a hydroxyl group and a resin containing a carbamate group, an amino group and / or an epoxy group. With the adoption of the copper clad laminate, as the dielectric constant and the dielectric loss of the copper clad laminate can be controlled by changing the content of the modified crosslinking type PTFE resin, the copper clad laminate has low and stable dielectric constant and lower dielectric loss; the copper clad laminate has the advantages that the manufacturing is simple, the process is feasible, and the cost is low.

Owner:SHANGHAI QUANKE INT TRADING CO LTD

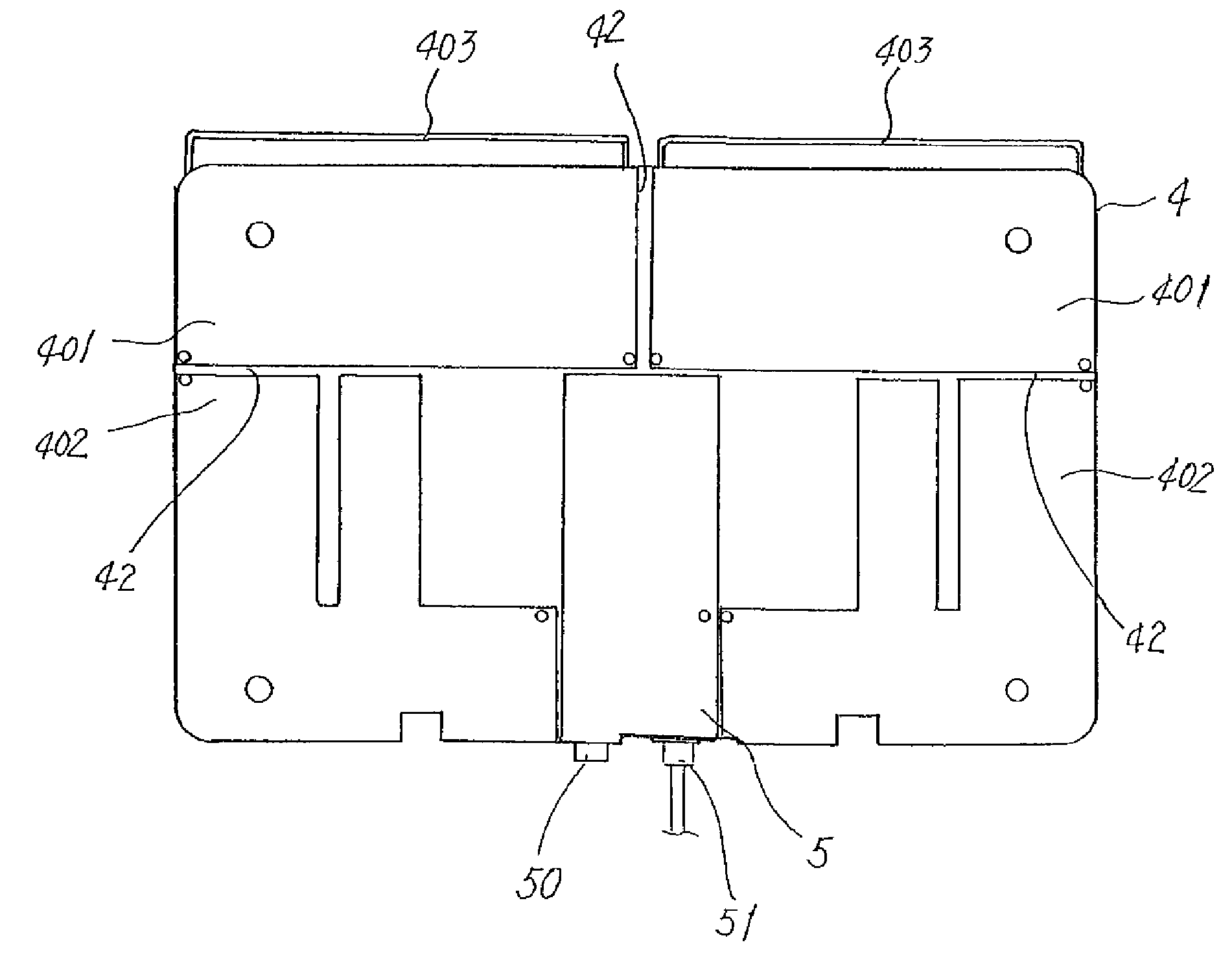

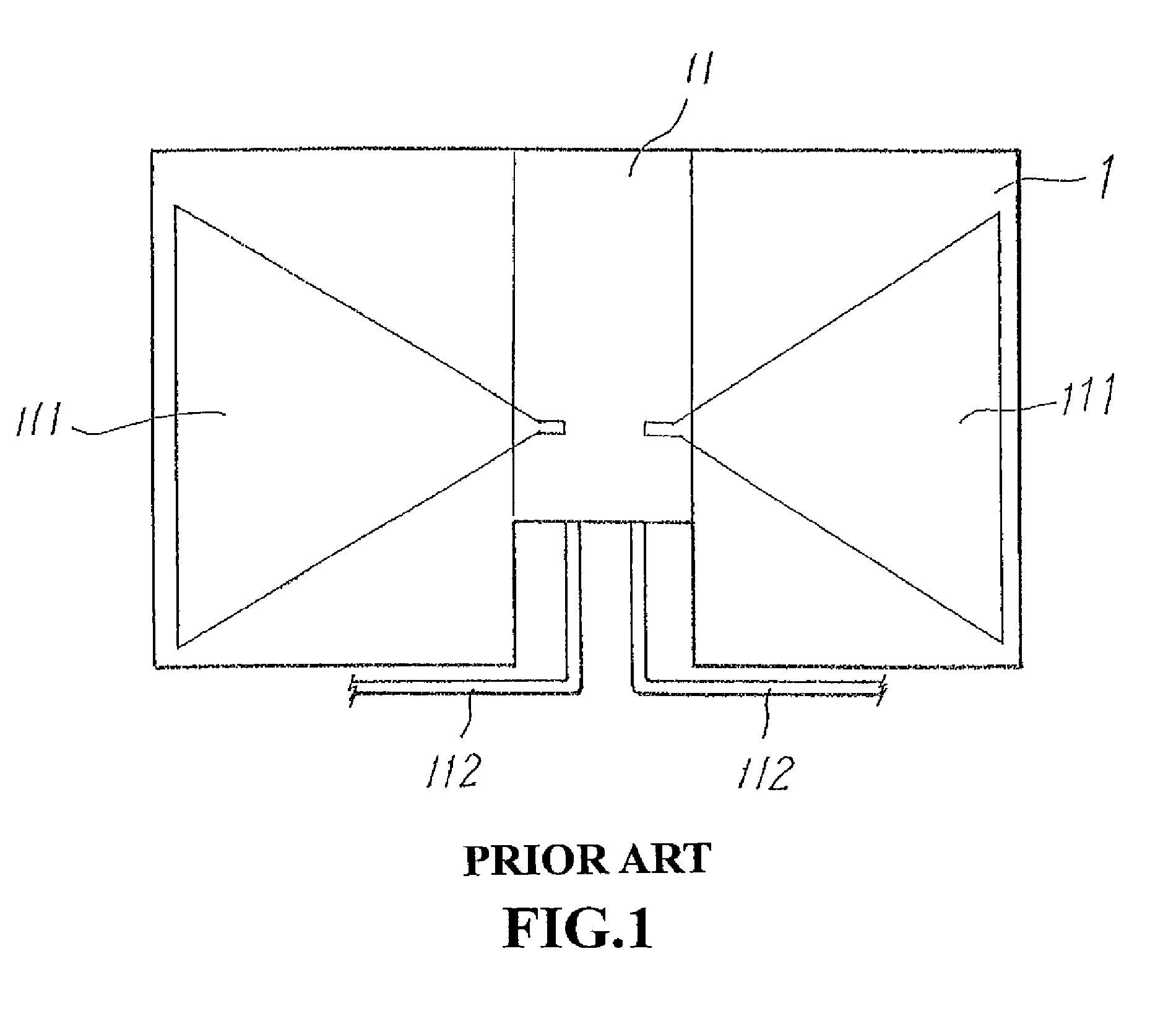

Multi-directional panel antenna

InactiveUS20110025578A1Increasing effective signal reception areaReduce dielectric lossSimultaneous aerial operationsAntenna supports/mountingsDielectric lossEngineering

A multi-directional panel antenna is provided for the reception of TV broadcast VHF and UHF signals. The panel antenna's circuit board has its current path substantially covers the surface of the circuit board so as to produce multi-directional reception patterns. An iron-core winding is configured at a feed-in terminal of the panel antenna for impedance matching and signal concentration. The panel antenna also uses air to reduce dielectric loss. A MMIC signal amplification device is provided for enhanced gain. Ceramic capacitors are provided to increase the reception wavelength of the panel antenna so that it falls within a lower section of the VHF band.

Owner:SAN WEN H K INT

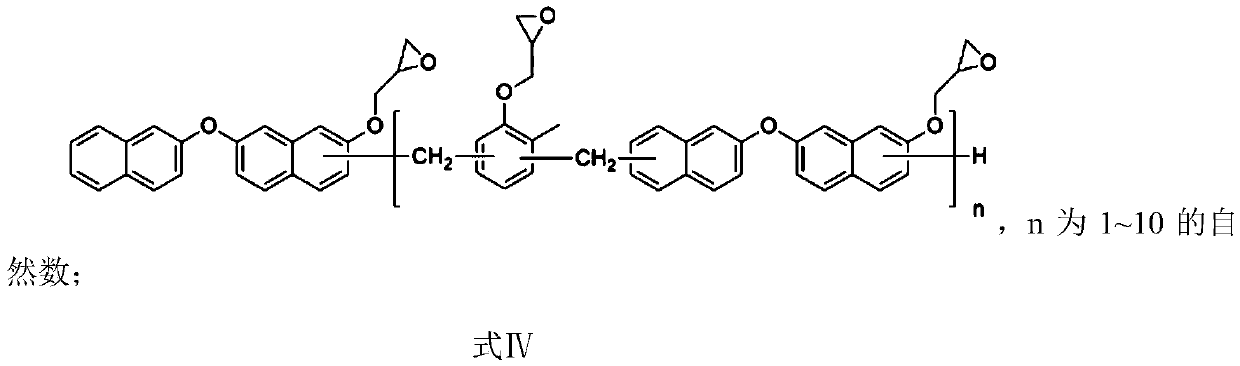

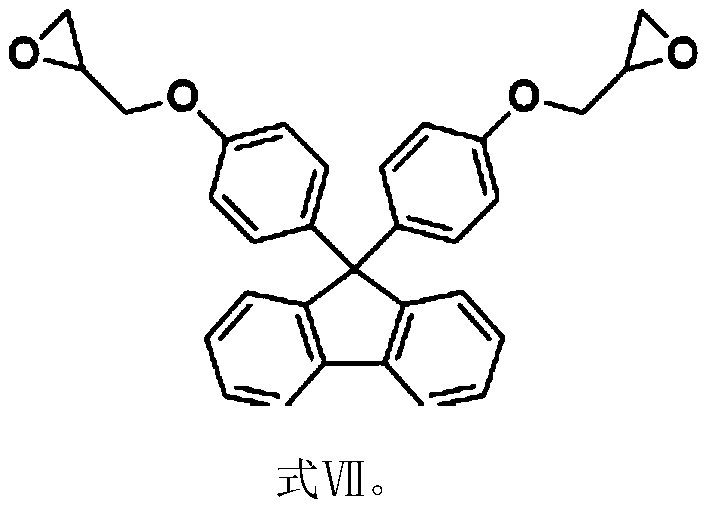

Resin composition and application thereof

ActiveCN110554567AImprove heat resistanceImprove resolutionHigh frequency circuit adaptationsPrinted circuit aspectsEpoxyDielectric loss

The invention provides a resin composition and an application thereof. The resin composition comprises the following components in parts by weight: 100 parts of alkali-soluble resin, 5-30 parts of acrylate monomer, 0.1-10 parts of photoinitiator, 10-30 parts of first epoxy resin and 0-15 parts of second epoxy resin, wherein the first epoxy resin is low-dielectric epoxy resin with a dielectric constant less than 3.5, and the second epoxy resin is different from the first epoxy resin. By adding the low-dielectric epoxy resin with the dielectric constant less than 3.5 and adjusting the ratio of all the components, the dielectric constant and the dielectric loss are remarkably reduced, the dielectric constant is reduced to 3.0 or below, and the dielectric loss is reduced to 0.008 or below. Inaddition, the resin composition has the advantages of good heat resistance, good resolution, small rebound force, and relatively good flexibility and bending resistance. Meanwhile, the resin composition is a photosensitive resin composition, and can realize image transfer through photosensitive development.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

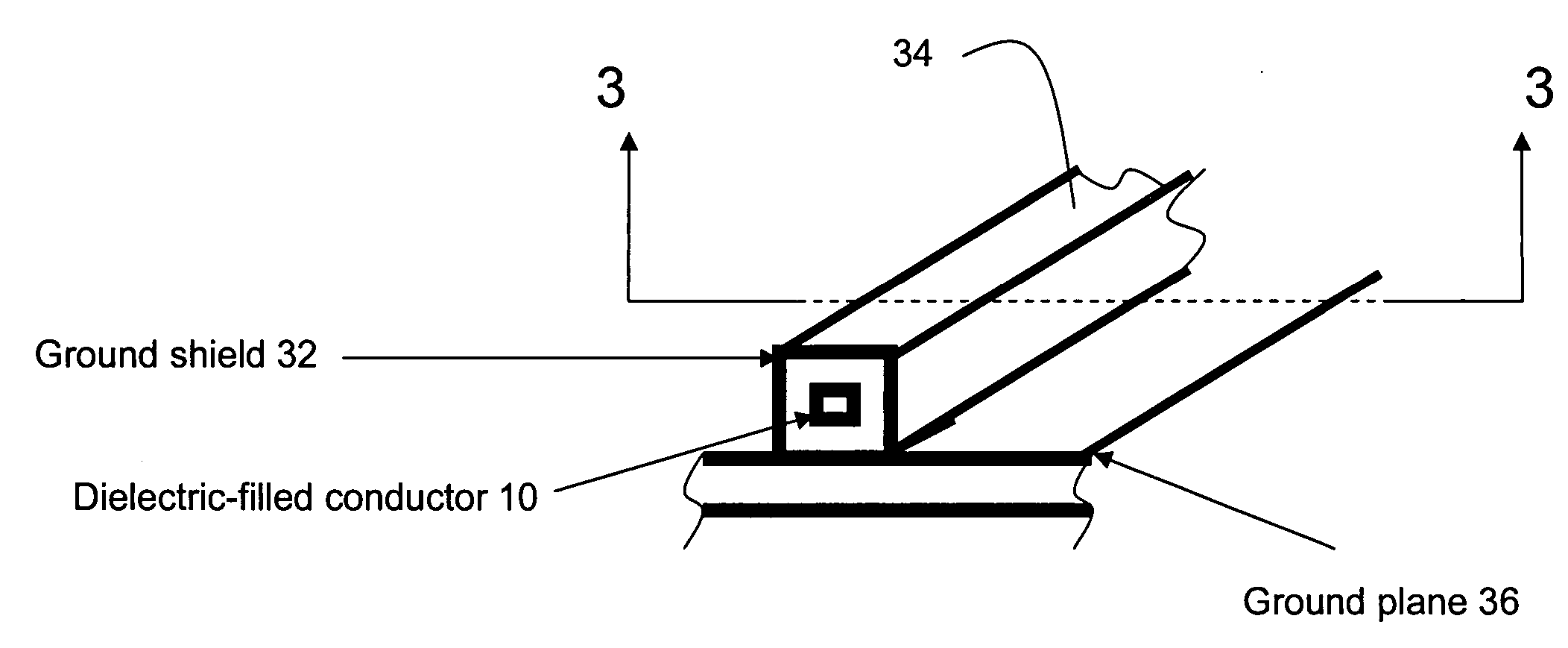

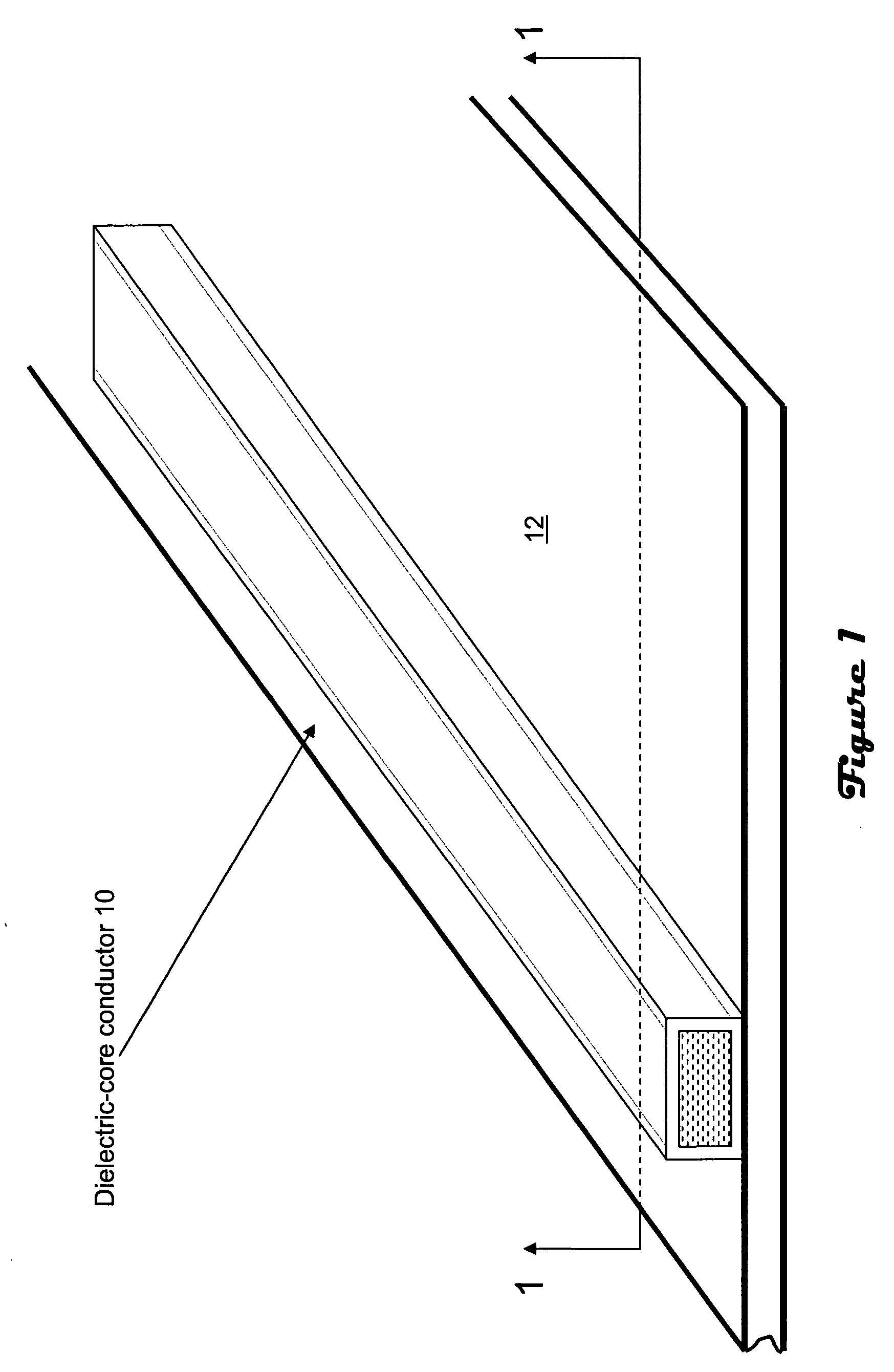

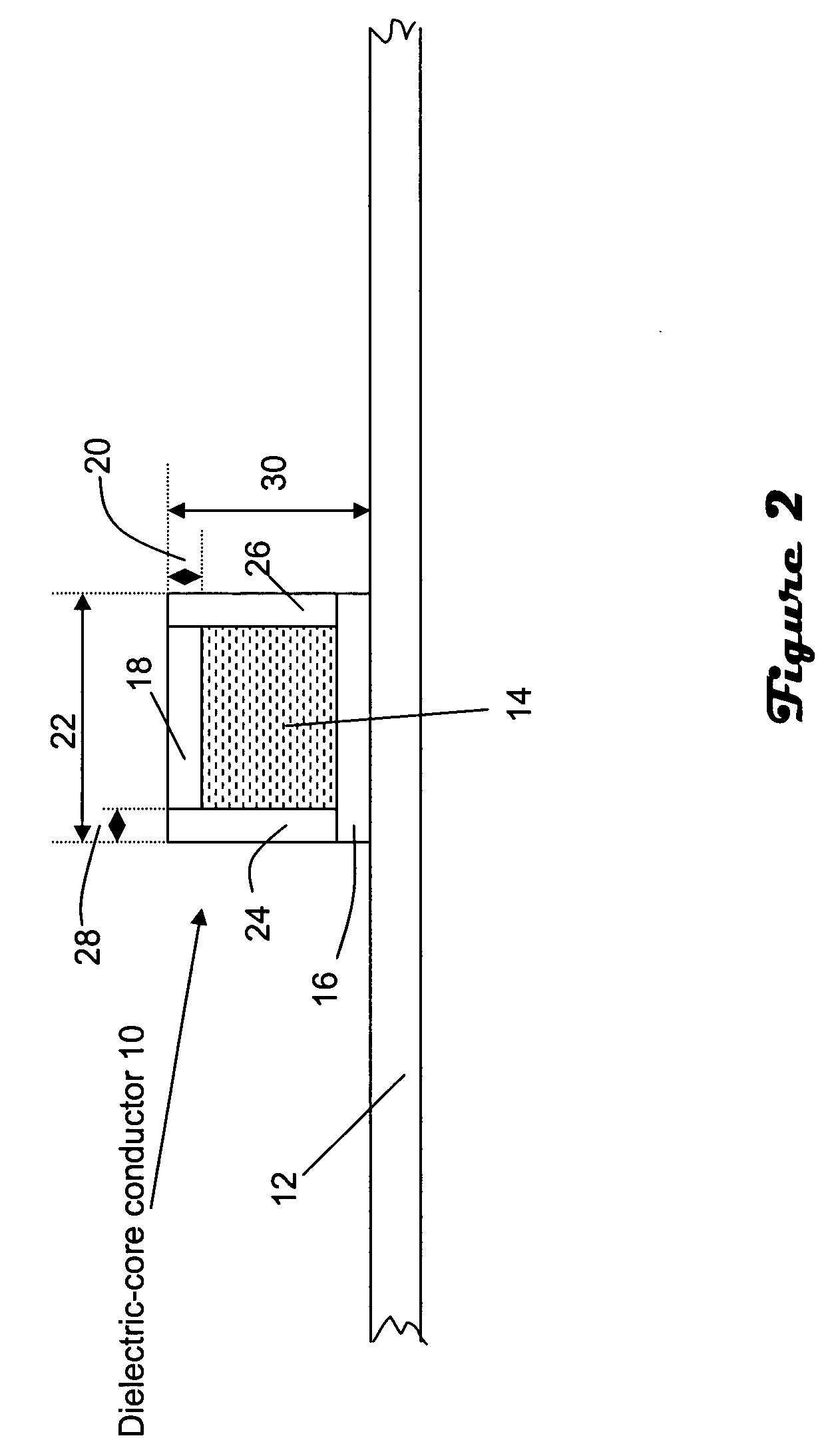

Dielectric-filled transmission lines

InactiveUS20060012452A1Increase surface areaCut skinMultiple-port networksHigh frequency circuit adaptationsDielectricPrinted circuit board

A printed circuit board transmission line has an outer conductive wall surrounding an inner dielectric core. The transmission line may be disposed inside a grounded shielding to provide a form of coaxial conductor that mitigates cross talk from adjacent transmission lines and EMI. Further, groups of dielectric-core transmission lines may be disposed within a single grounded shield. For example, edge coupled differential pairs may be disposed in parallel with each other on a plane defined by a layer of the printed circuit board, i.e., side-by-side. Further, broadside-coupled differential pairs of dielectric-core transmission lines may be disposed in parallel with each other in a stack which is orthogonal with the plane defined by a layer of the printed circuit board, i.e., one on top of the other. Further, a plurality of dielectric-core transmission lines which may include all or ones of single-ended lines and differential pairs may be disposed within a single grounded shield.

Owner:RPX CLEARINGHOUSE

Polyolefins made by catalyst comprising a noncoordinating anion and articles comprising them

ActiveUS20050123778A1Low mobilityReduce dielectric lossOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsPolymer sciencePolyolefin

Polymers made by transition metal catalyst systems comprising a bulky noncoordinating anion (NCA) as cocatalyst component. In comparison to polymers containing a conventional NCA, these polymers show a considerably lower dielectric loss, making them suitable for insulation applications such as for power cable.

Owner:EXXONMOBIL CHEM PAT INC

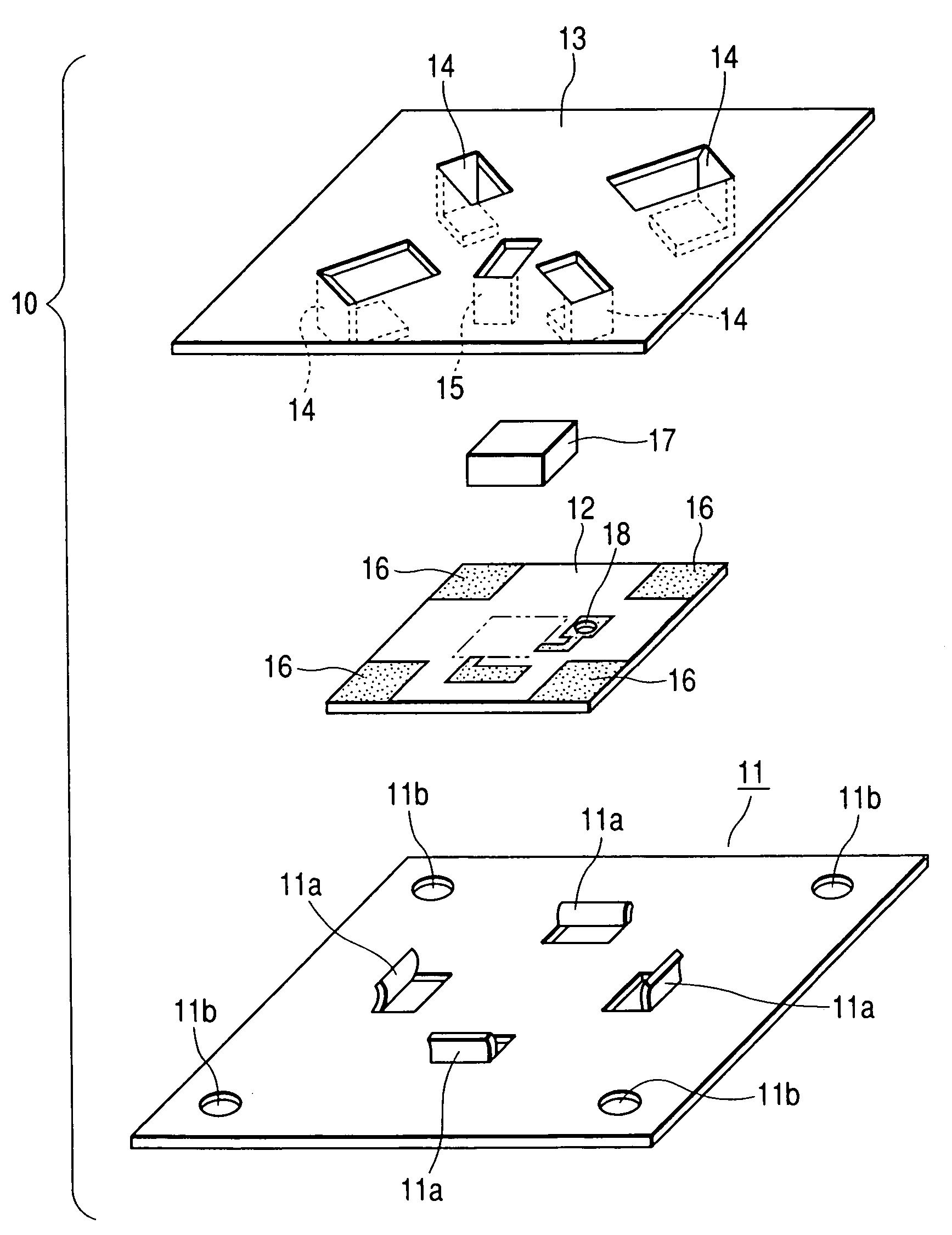

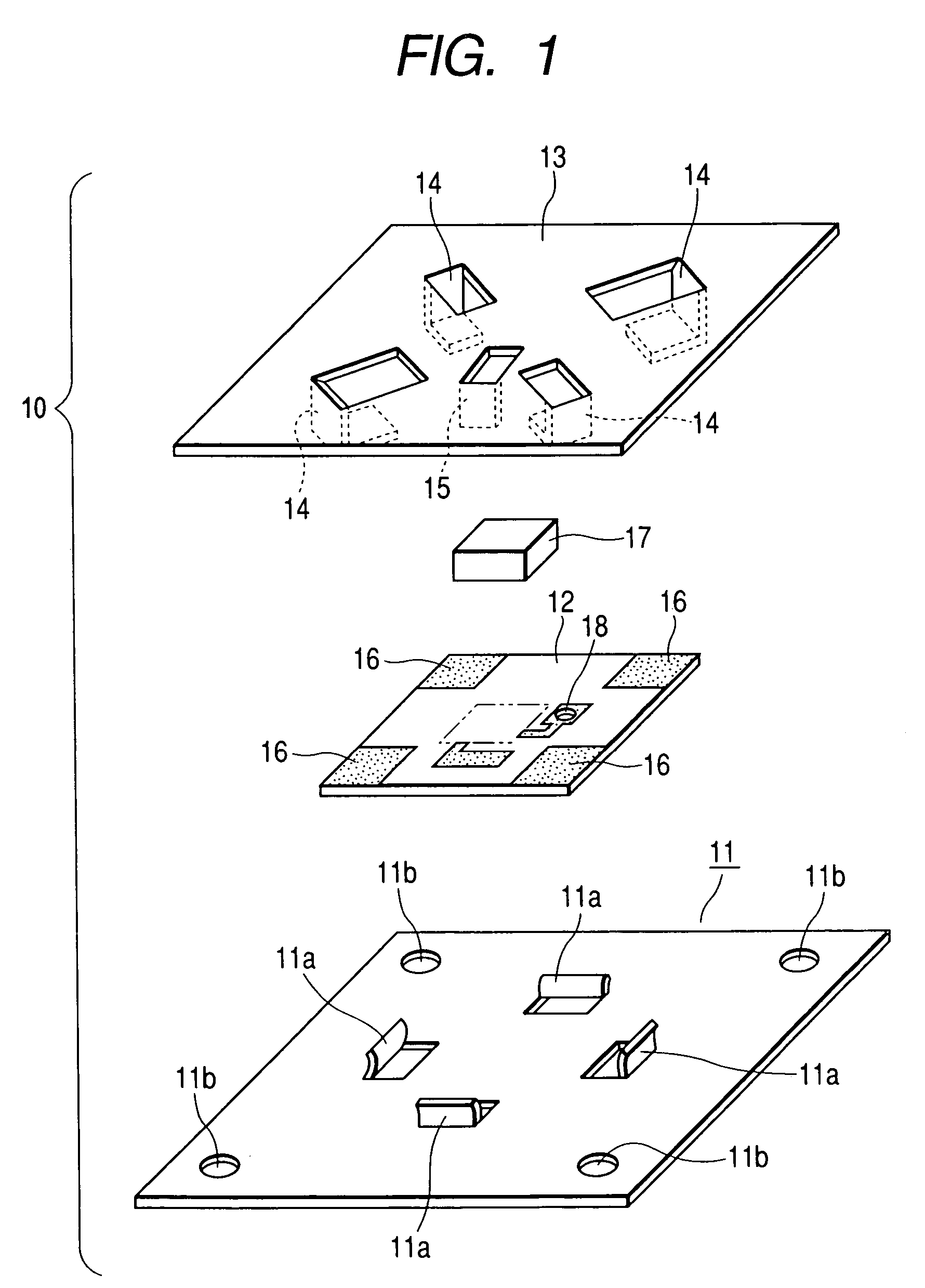

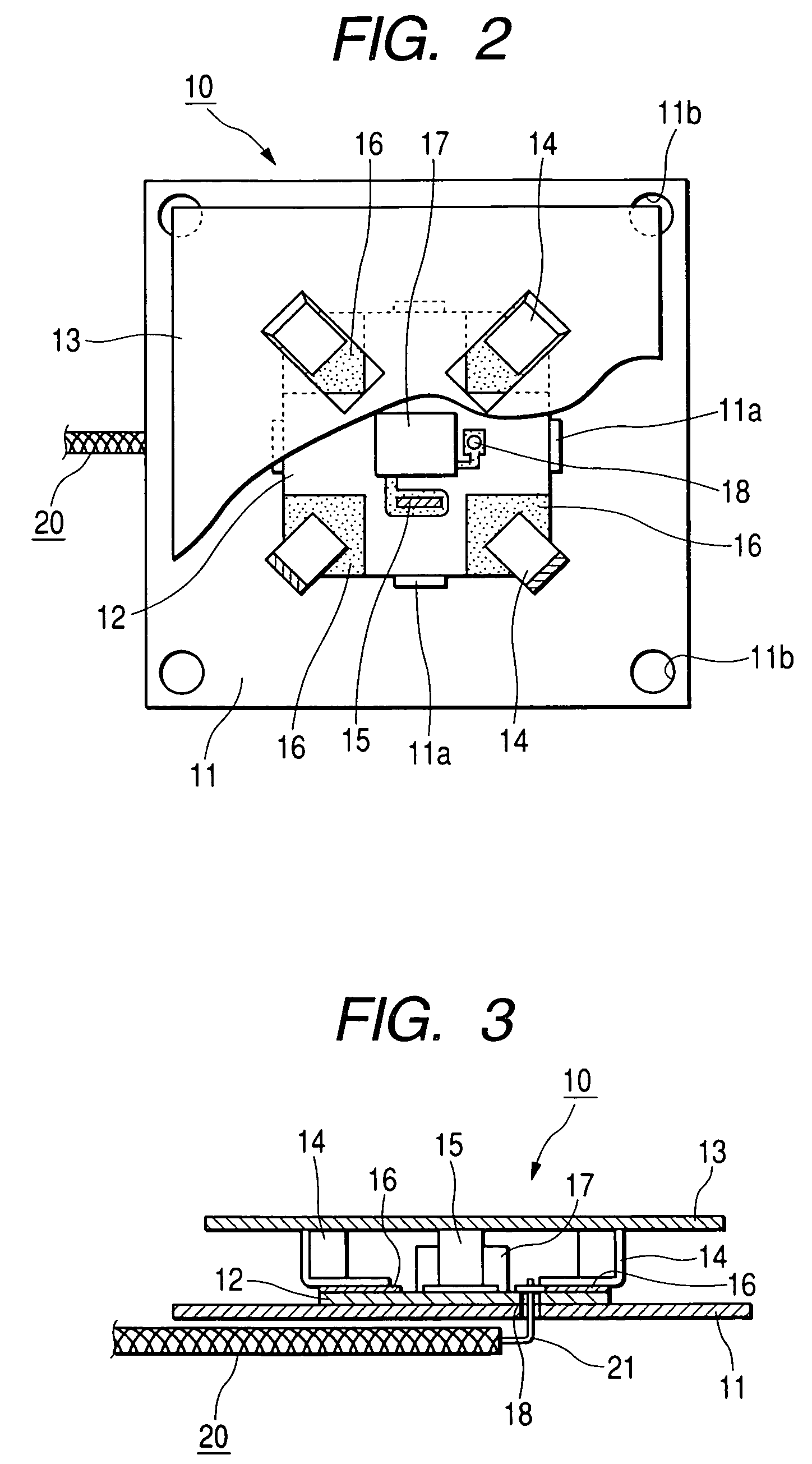

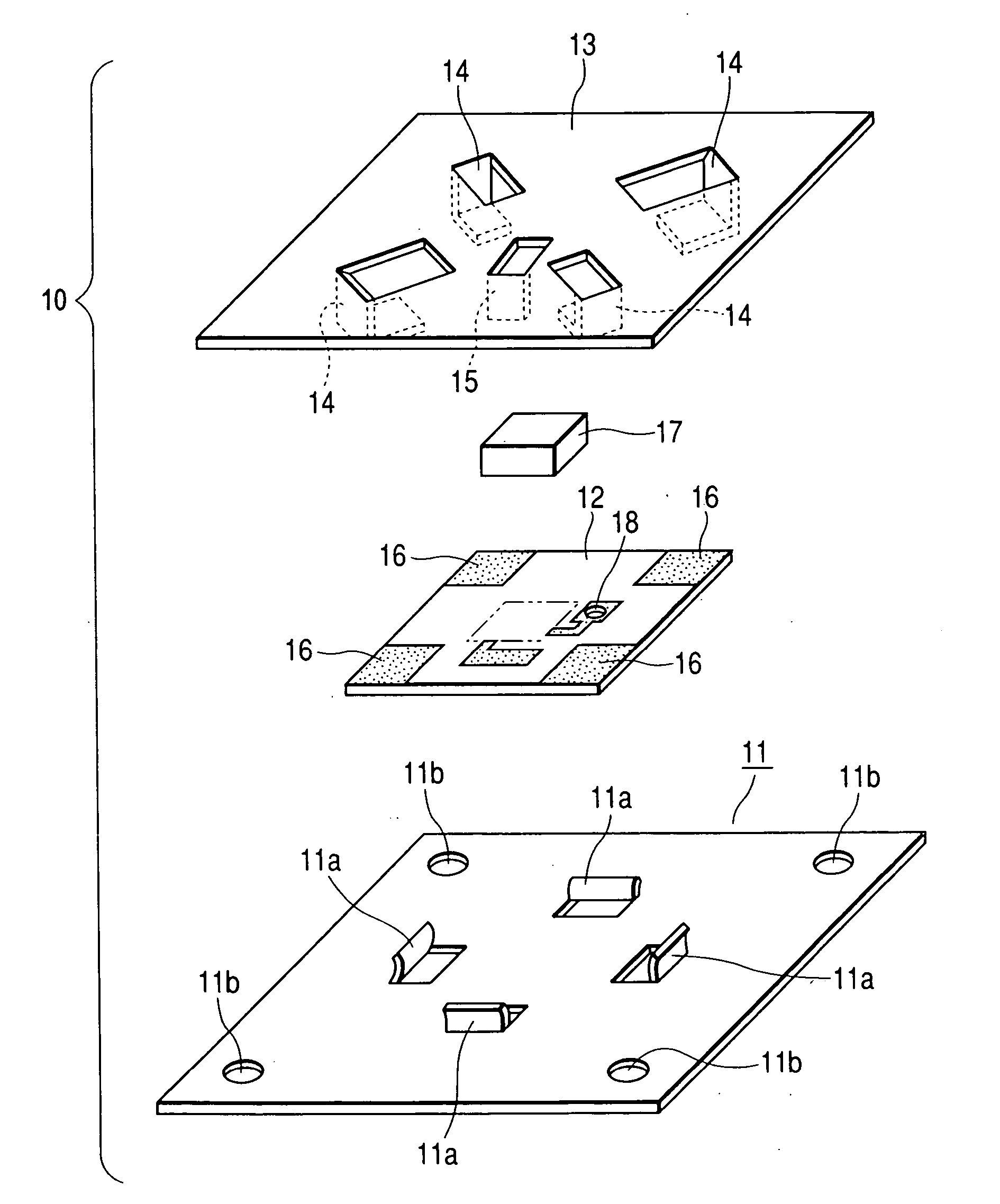

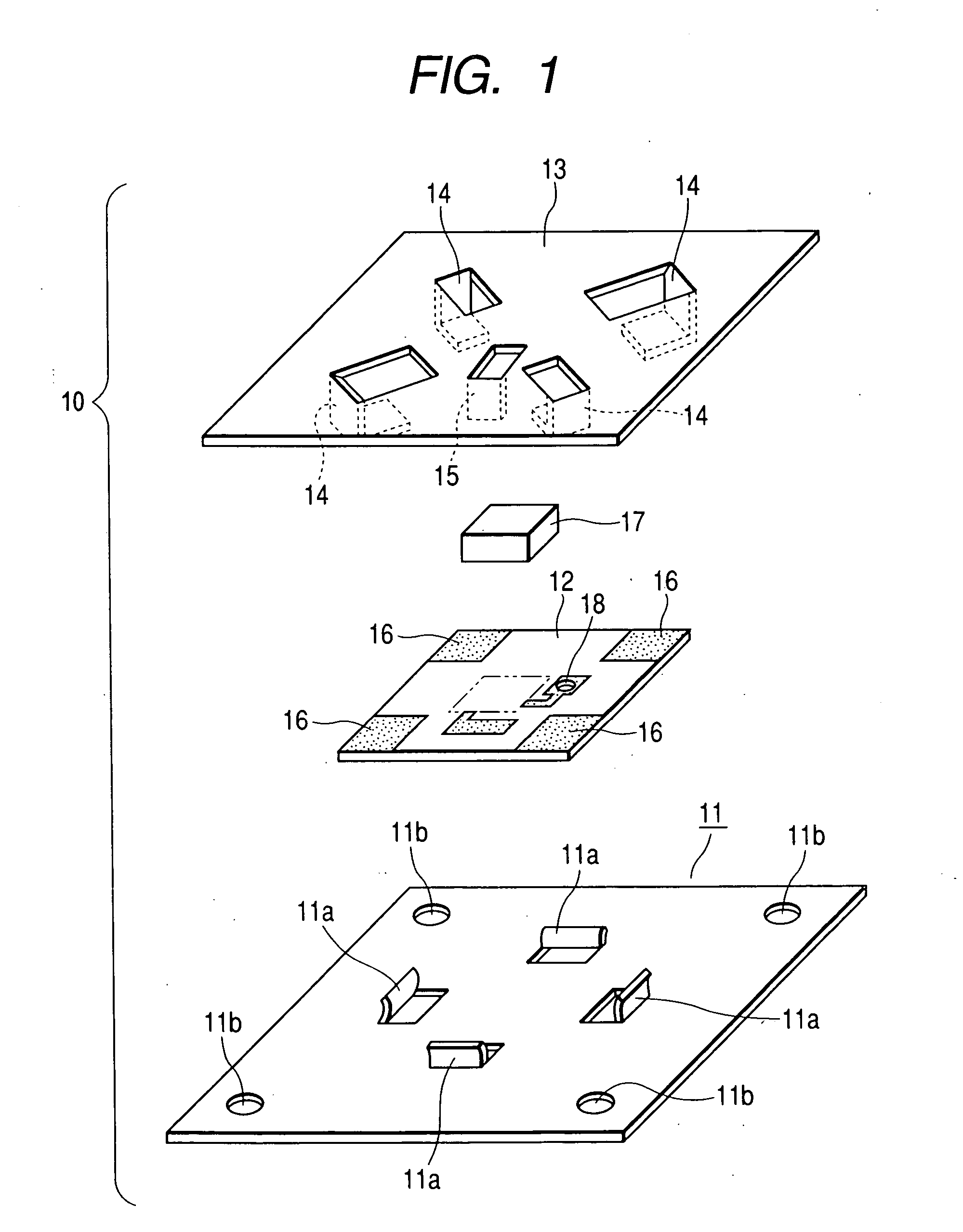

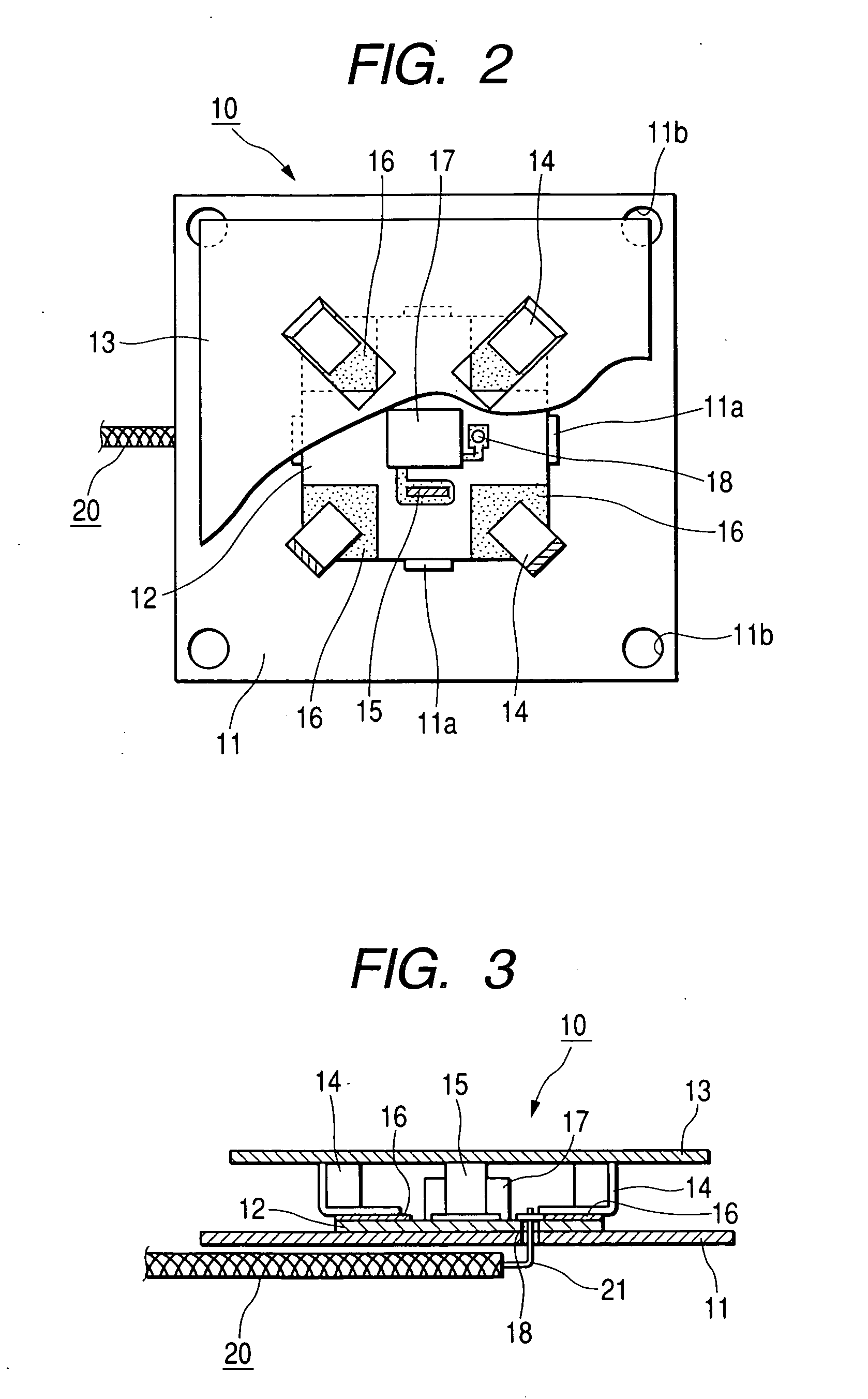

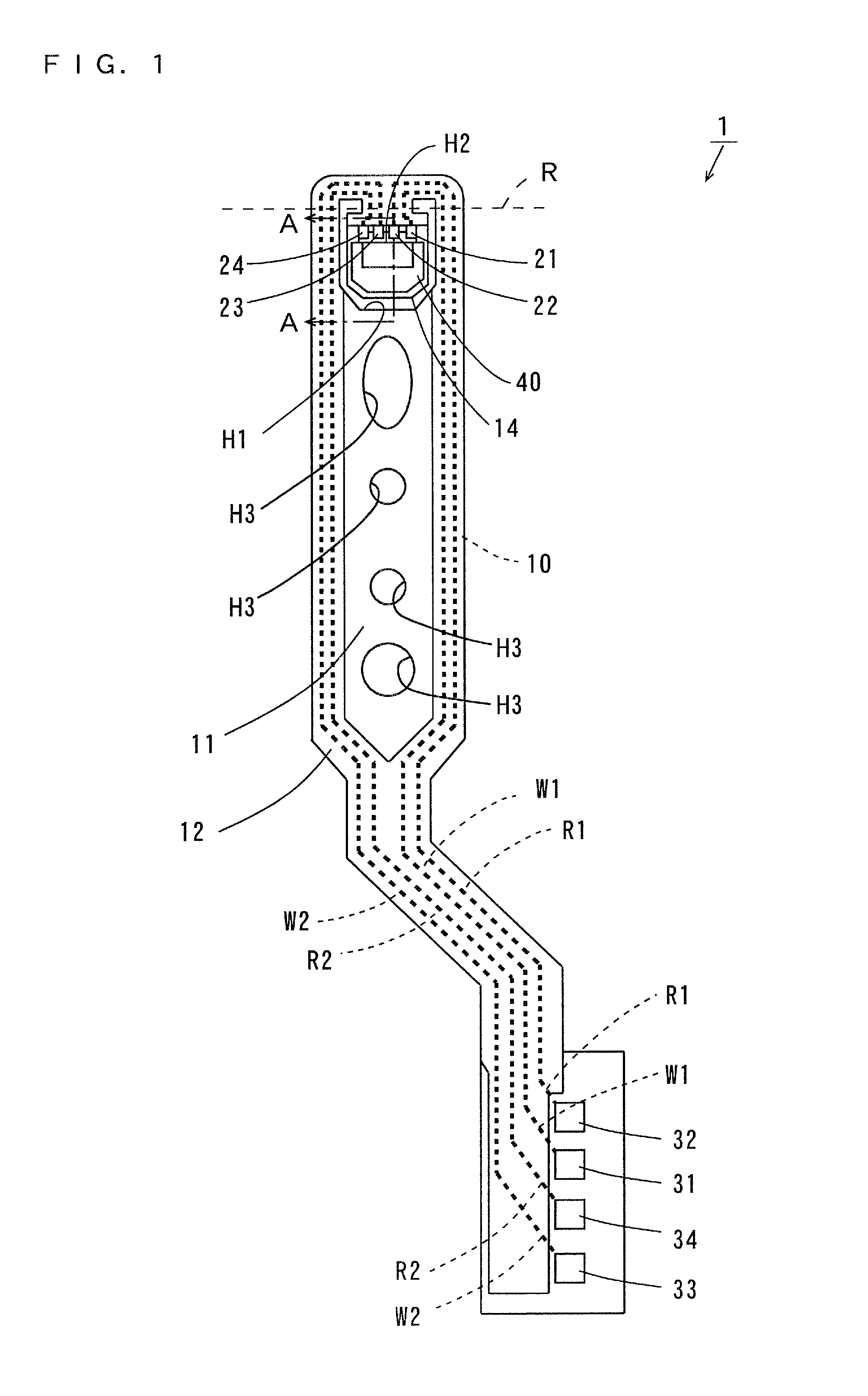

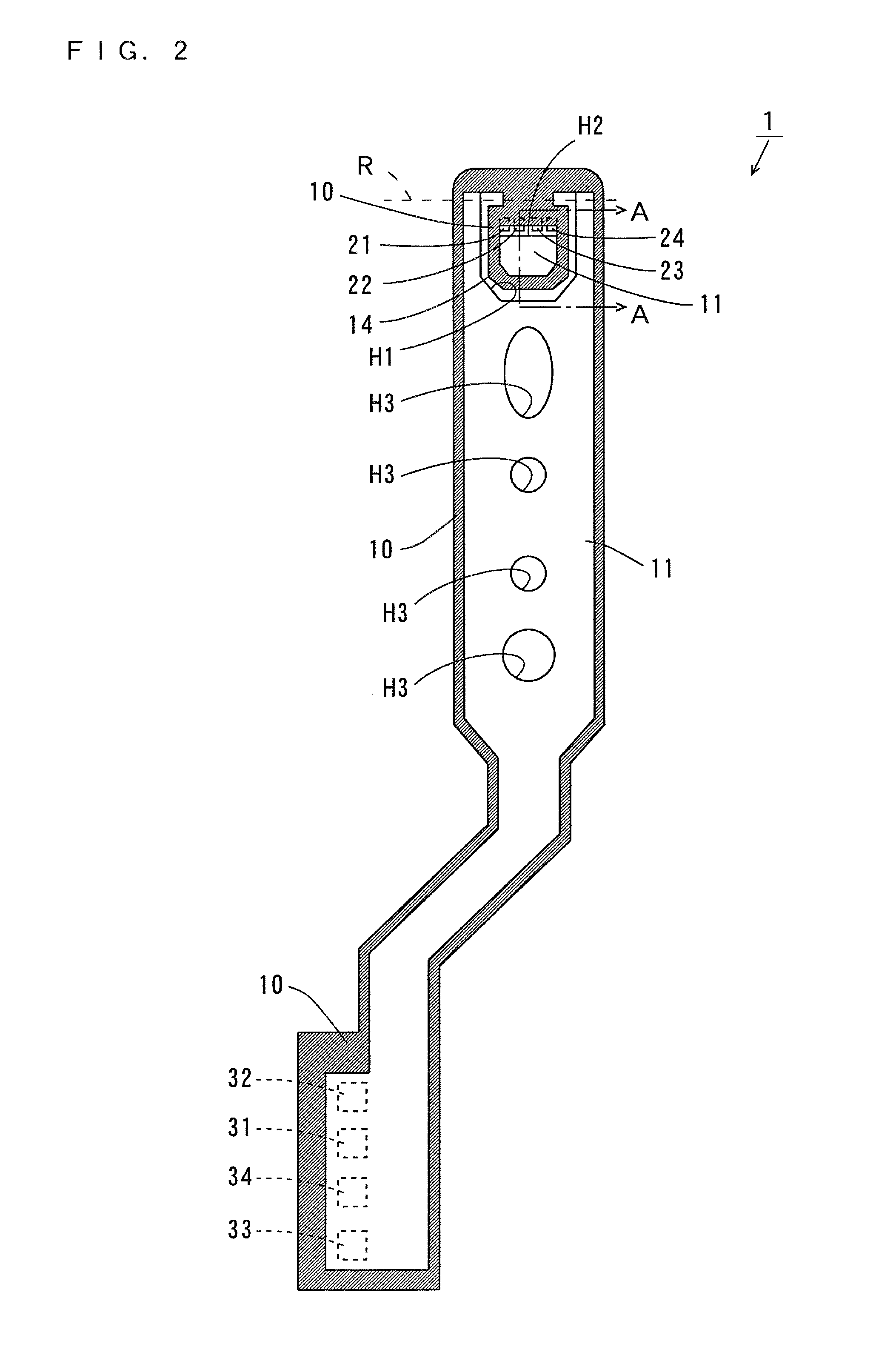

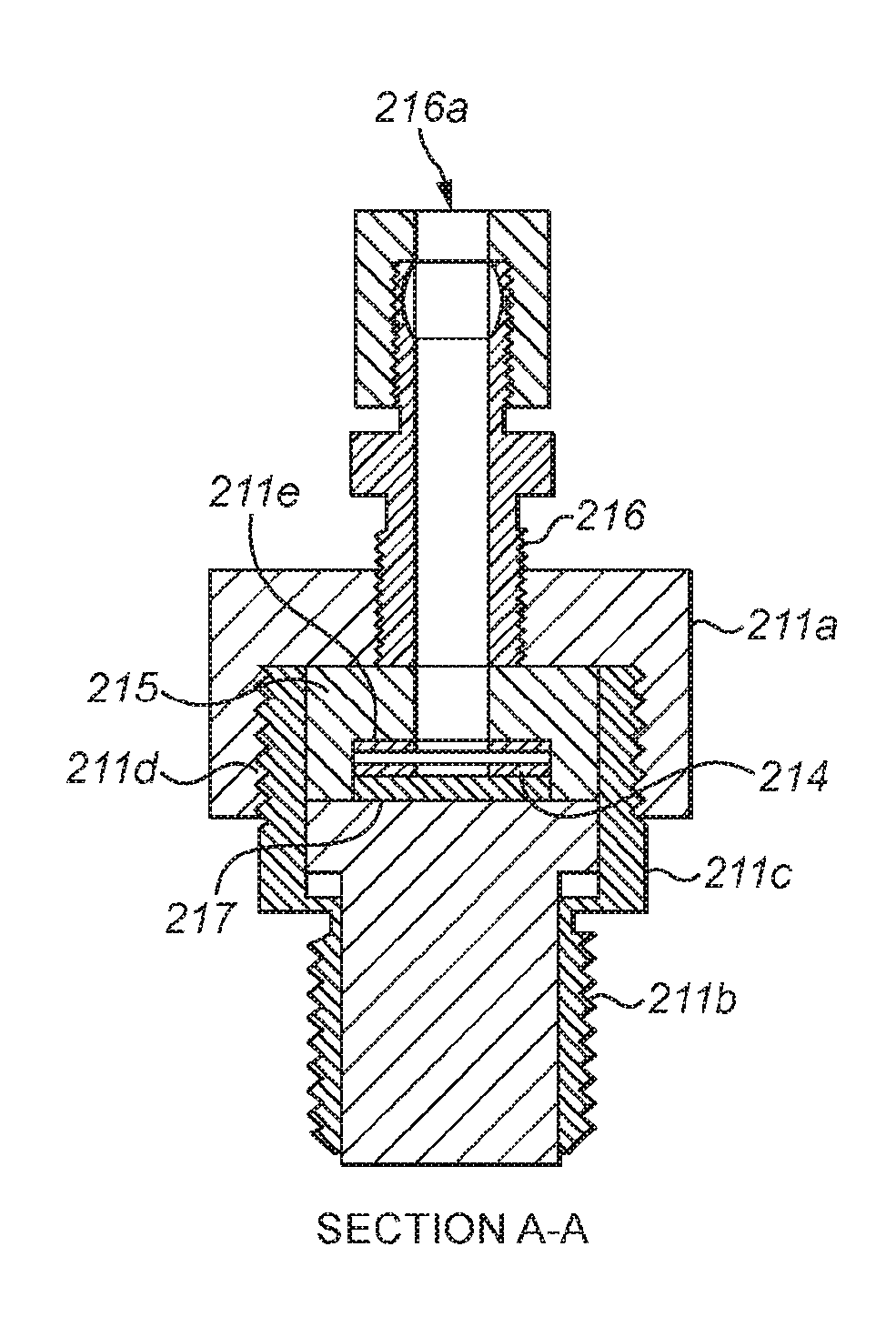

Antenna device having miniaturized radiating conductor plate

ActiveUS7046203B2Reduce dielectric lossReduce manufacturing costSimultaneous aerial operationsAntenna supports/mountingsDielectric substrateEngineering

A metal plate patch antenna 10 includes a ground conductor composed of a metal plate, a dielectric substrate placed on and fixed to the ground conductor, a radiating conductor plate composed of a metal plate arranged above the dielectric substrate with a predetermined gap therefrom, leg pieces formed by cutting and raising four places near the outer circumferential portion of the radiating conductor plate toward the dielectric substrate, and a feeding metal piece extending from a feeding point of the radiating conductor plate. Soldering lands are arranged at four corners of the top surface of the dielectric substrate so that lower ends of the leg pieces are respectively soldered to the soldering lands.

Owner:ALPS ALPINE CO LTD

Antenna device having miniaturized radiating conductor plate

ActiveUS20050093748A1Increase capacitanceSmall sizeSimultaneous aerial operationsAntenna supports/mountingsDielectric substrateSoldering

A metal plate patch antenna 10 includes a ground conductor composed of a metal plate, a dielectric substrate placed on and fixed to the ground conductor, a radiating conductor plate composed of a metal plate arranged above the dielectric substrate with a predetermined gap therefrom, leg pieces formed by cutting and raising four places near the outer circumferential portion of the radiating conductor plate toward the dielectric substrate, and a feeding metal piece extending from a feeding point of the radiating conductor plate. Soldering lands are arranged at four corners of the top surface of the dielectric substrate so that lower ends of the leg pieces are respectively soldered to the soldering lands.

Owner:ALPS ALPINE CO LTD

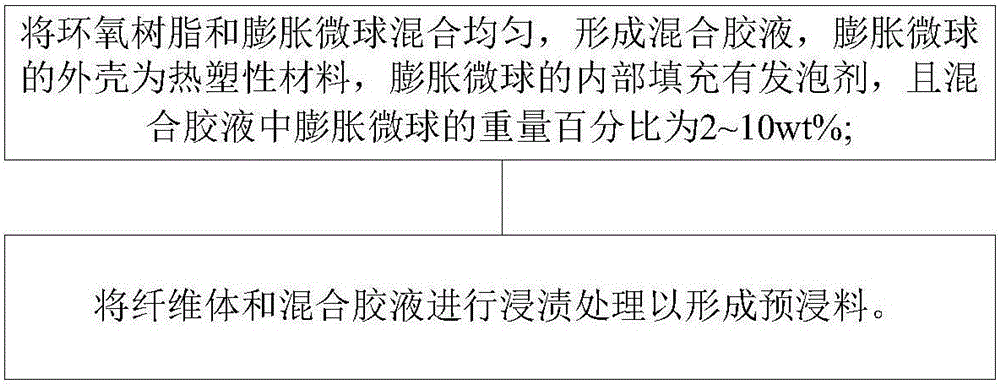

Prepreg, preparation method of prepreg and composite material

The invention provides a prepreg, a preparation method of the prepreg and a composite material. The prepreg is an impregnation compound comprising epoxy resin, expended microspheres and a fiber body. The invention provides a prepreg of the impregnation compound comprising the epoxy resin, expended microspheres and the fiber body, wherein the shell of the expended microspheres is a thermoplastic material, and a foaming agent is filled in the shell, so that the expended microspheres have higher density than hollow microspheres, and the stability of the mixed glue solution is further improved. Moreover, because the expended microspheres with a certain weight percentage exist in the prepreg, the content of other medium materials in the prepreg is reduced; and because the dielectric constant of the other medium materials is higher than the dielectric constant of the expended microspheres, the dielectric constant and dielectric loss of the prepreg are reduced.

Owner:KUANG CHI INST OF ADVANCED TECH

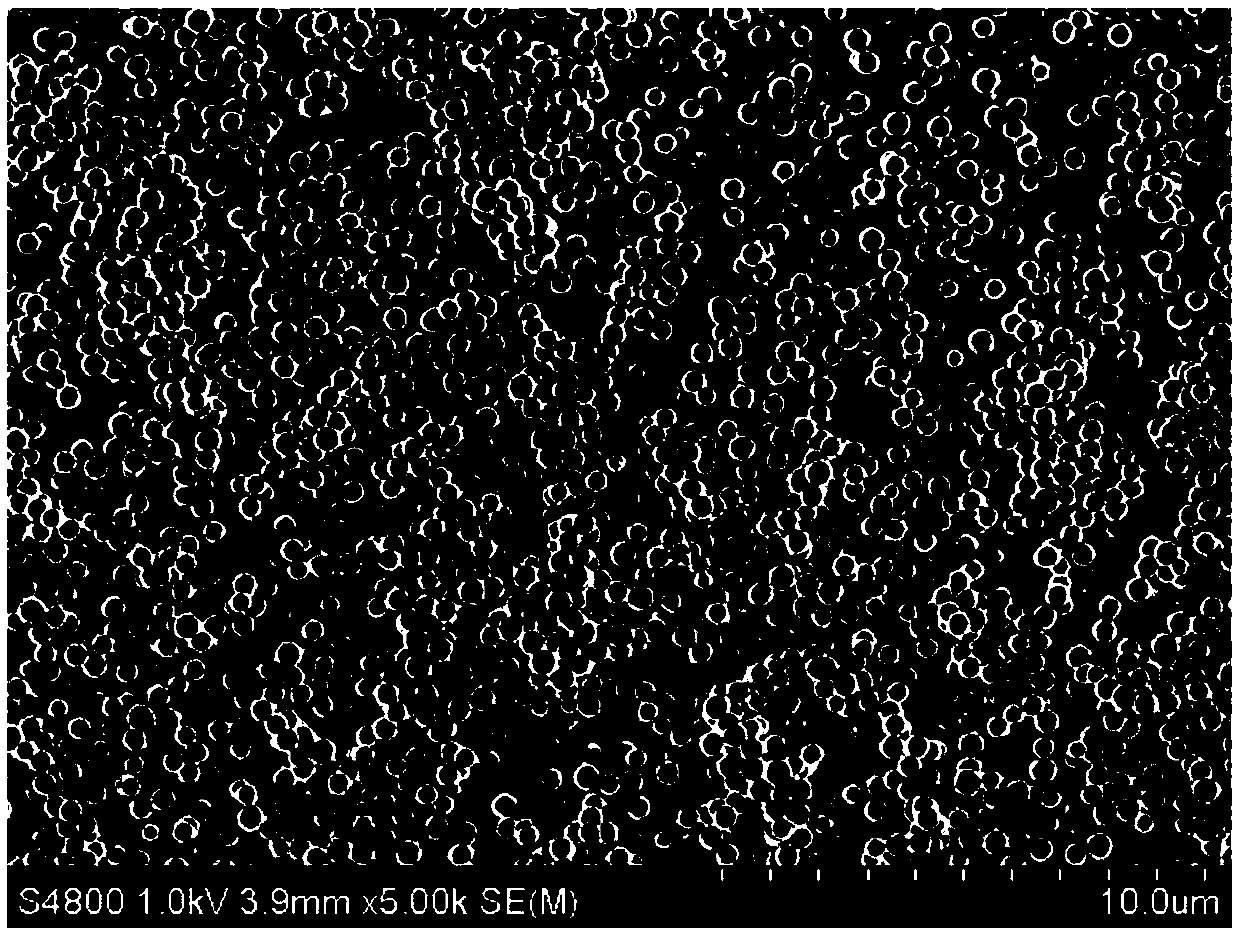

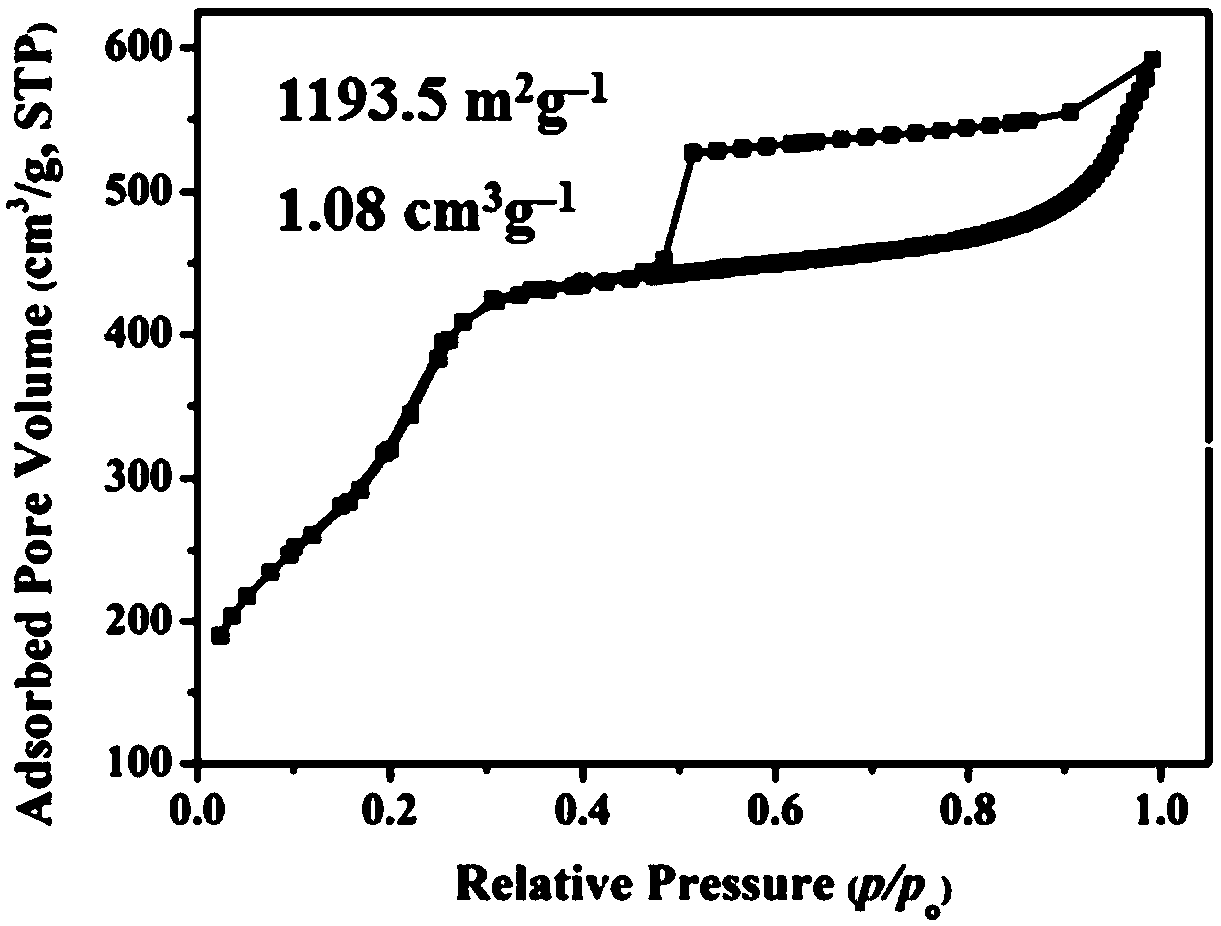

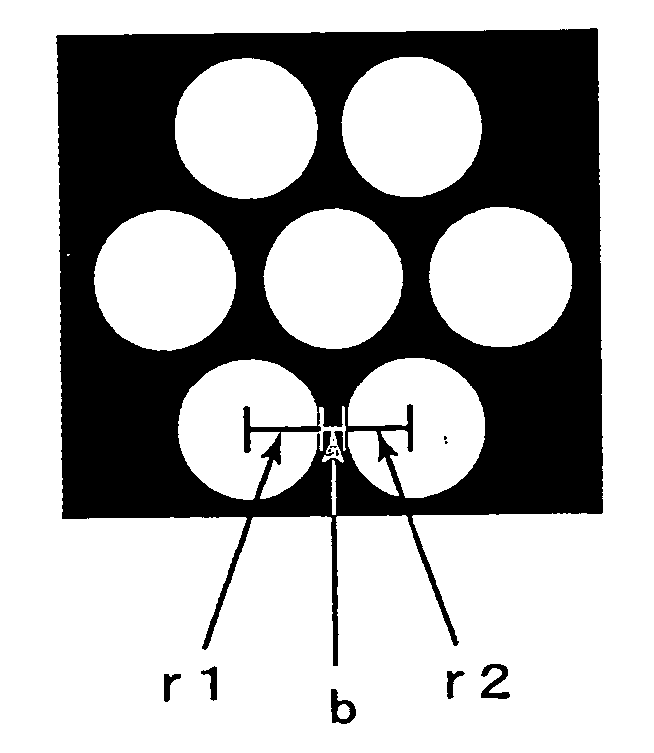

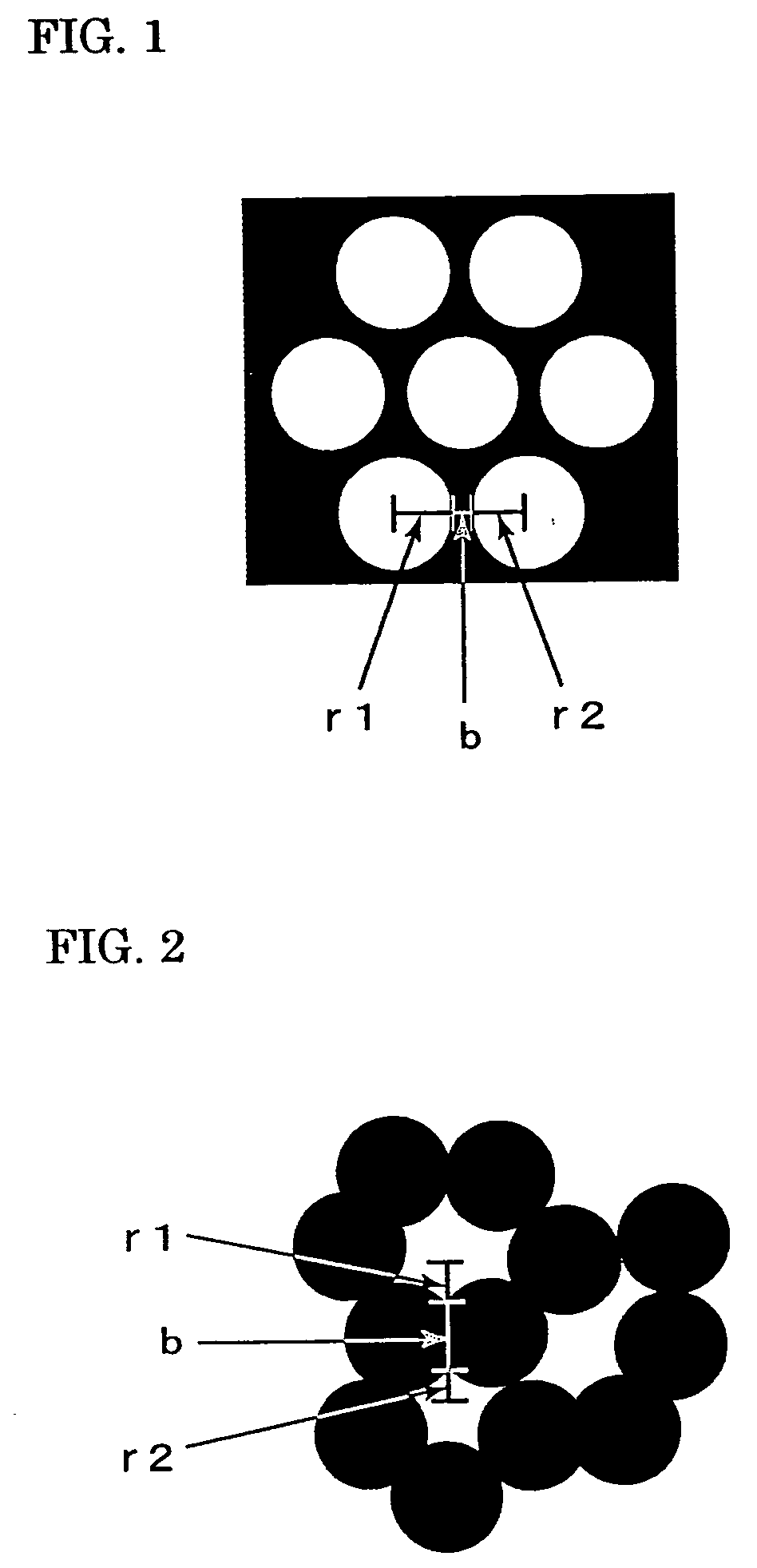

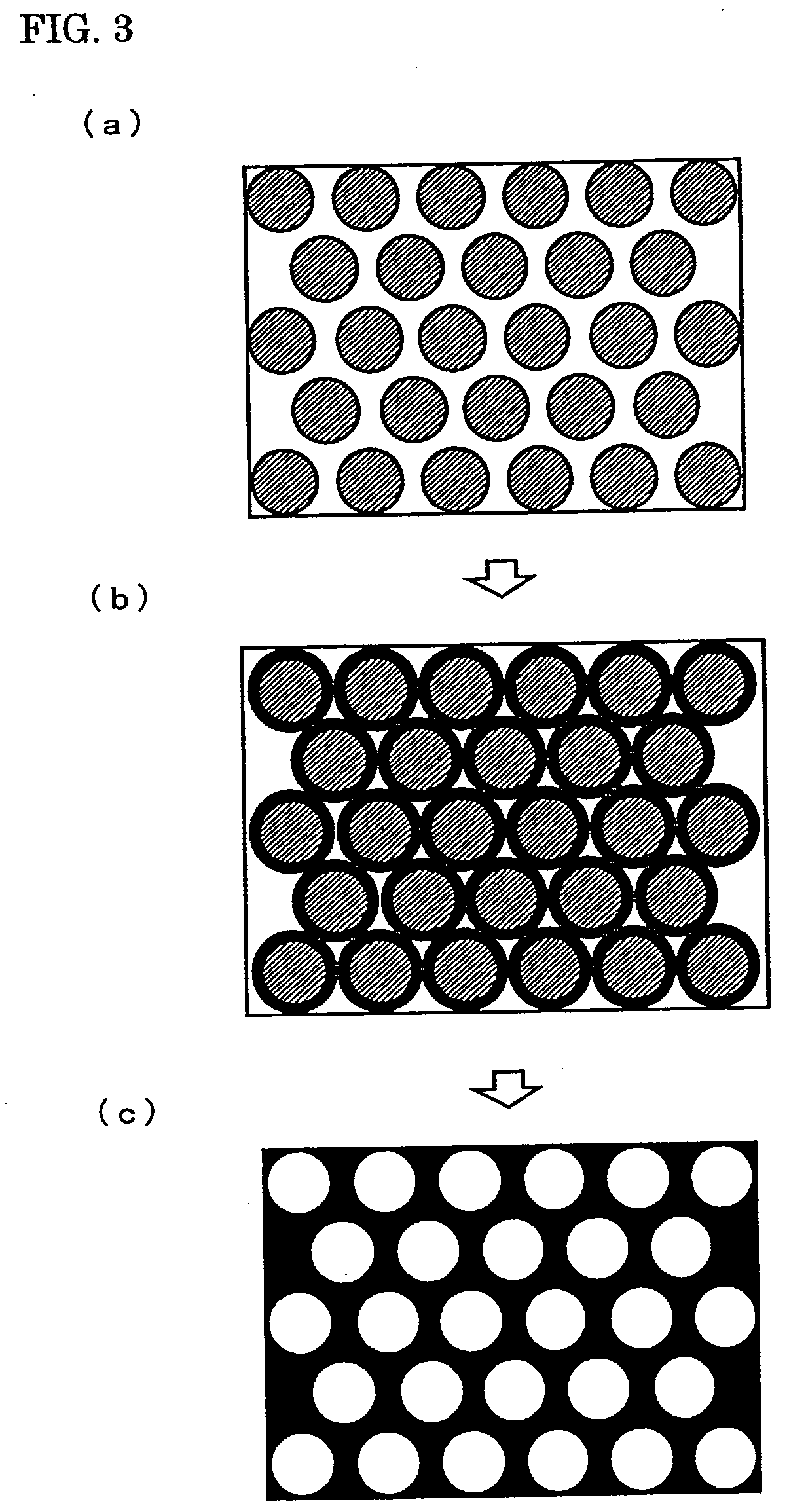

Monodisperse hollow mesoporous silicon oxide microsphere material and double-surfactant induced assembly preparation method thereof

InactiveCN109675506AEffectively adjust the speed of hydrolysis and crosslinkingLow dielectric constantMicroballoon preparationMicrocapsule preparationAlcoholMicrosphere

The invention relates to a monodisperse hollow mesoporous silicon oxide microsphere material and a double-surfactant induced assembly preparation method thereof. The monodisperse hollow mesoporous silicon oxide microsphere material has a hollow microsphere morphology, the microsphere diameter size is 200-1000nm, the hollow size of 50-700nm, an outer shell adopts a mesoporous structure, the shell thickness is 50-500nm, the mesoporous size is 2-20nm, the specific surface area of the microspheres is 700-1200m<2> / g, and the pore volume is 0.3-0.85cm<3> / g. During preparation, an induced self-assembly method under mutual assistance of two surfactants, namely a nonionic amphiphilic triblock polymer surfactant and an ionic organic surfactant, is adopted, and in a simple mixed solvent of alcohol and water, in a sol-gel way of dropwise adding a silicon source precursor, centrifuging, washing and calcinating treatment is performed to obtain the size-controllable, monodisperse, mesoporous, high-specific surface area and large-pore volume silicon oxide microsphere material. Compared with the prior art, the invention has the advantages of simple operation, good repeatability, easy obtainment ofraw materials, low cost, capability of achieving industrial preparation and the like.

Owner:元颉新材料科技(浙江)有限公司

Porous silicon nitride ceramics and method for producing the same

InactiveUS20040013861A1Reduce dielectric lossExcellent in electrical/mechanical characteristicDielectric heatingOptical articlesGrain boundaryPorous silicon

The invention provides porous silicon nitride ceramics that have uniform, fine closed pores and a manufacturing method thereof. Metal Si powder is mixed with a sintering additive, followed by thermal treatment, which is a pre-process for forming a specific grain boundary phase. Two-stage thermal treatment is thereafter performed by microwave heating at a temperature of 1000° C. or more. The metal Si powder is thereafter subjected to a nitriding reaction from its surface, the metal Si is thereafter diffused to nitride formed on the outer shell of the metal Si, and thereby porous silicon nitride ceramics that have uniform, fine closed pores can be obtained. Since the porous silicon nitride ceramics of the present invention have a high ratio of closed pores and are superior in electrical / mechanical characteristics, excellent characteristics can be displayed if they are used, for example, for an electronic circuit board that requires an anti-hygroscopicity, a low dielectric constant, a low dielectric loss, and mechanical strength.

Owner:SUMITOMO ELECTRIC IND LTD

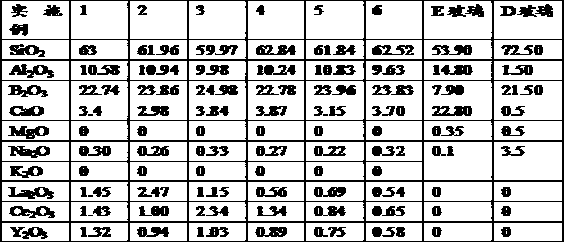

Rare earth oxide co-doped fluoride-free low-dielectric glass fiber and preparation method thereof

InactiveCN108423999ALow dielectric constantReduce dielectric lossGlass making apparatusFiberGlass fiber

The invention provides fluoride-free glass fiber with low dielectric constant and low dielectric loss. The dielectric constant and the dielectric loss of the glass fiber can reach better levels. The dielectric constant and the dielectric loss at 1 MHz are 4.17-4.87 and 4.24*10<-3>-6.28*10<-3> respectively. The dielectric property of glass is optimized through co-doping of rare earth. Glass fiber composition is prepared from raw materials in percentage by mole as follows: 55%-67% of SiO2, 18%-26% of B2O3, 6%-12% of Al2O3, 0.1%-1% of Na2O, 2%-7% of CaO and 0.5%-6% of La2O3, Ce2O3 and Y2O3. The glass fiber is suitable to be used as a reinforcing material of a printed circuit board.

Owner:UNIV OF JINAN

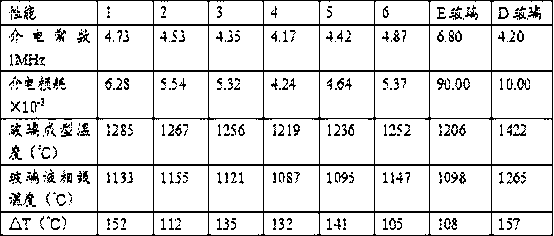

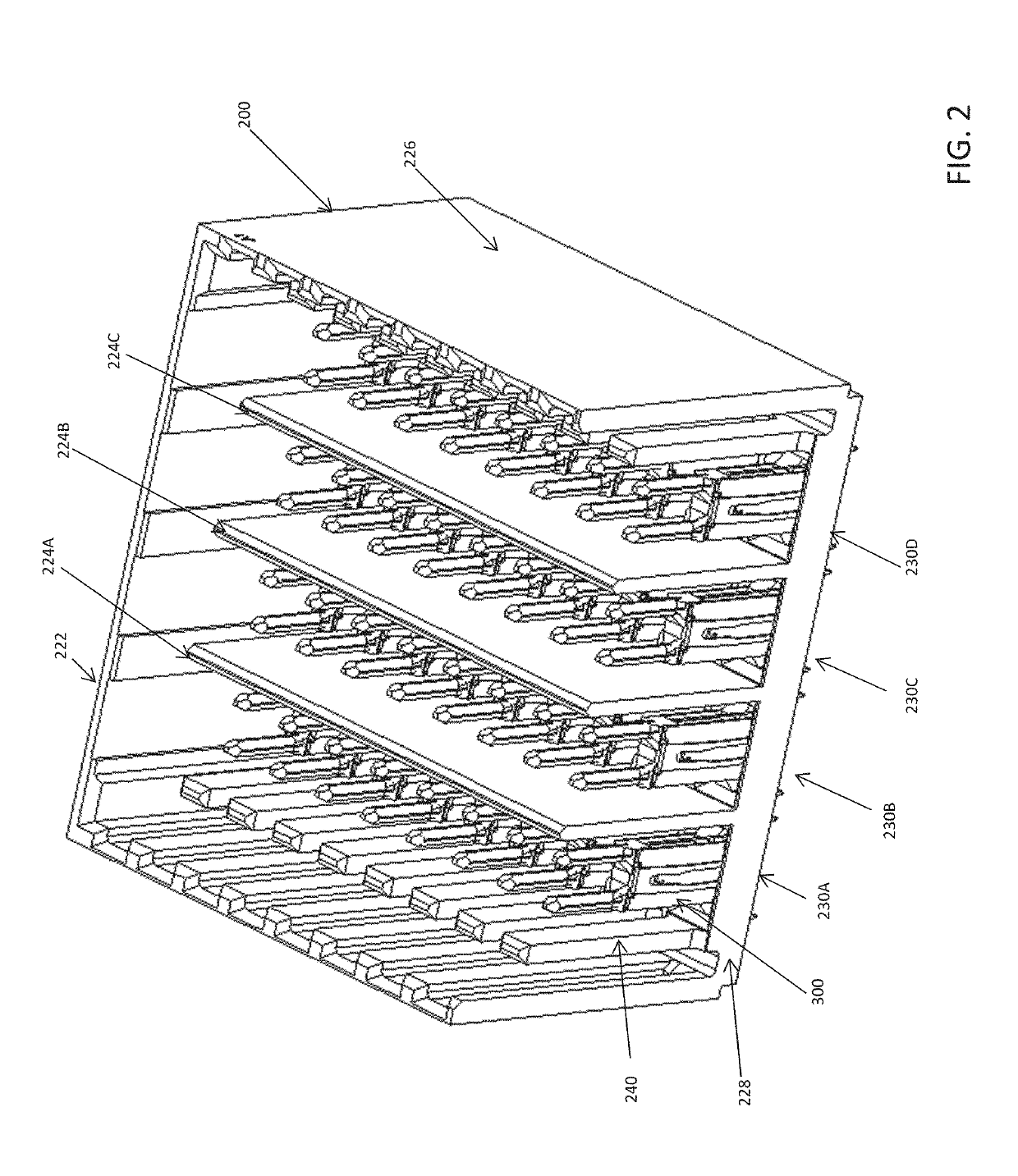

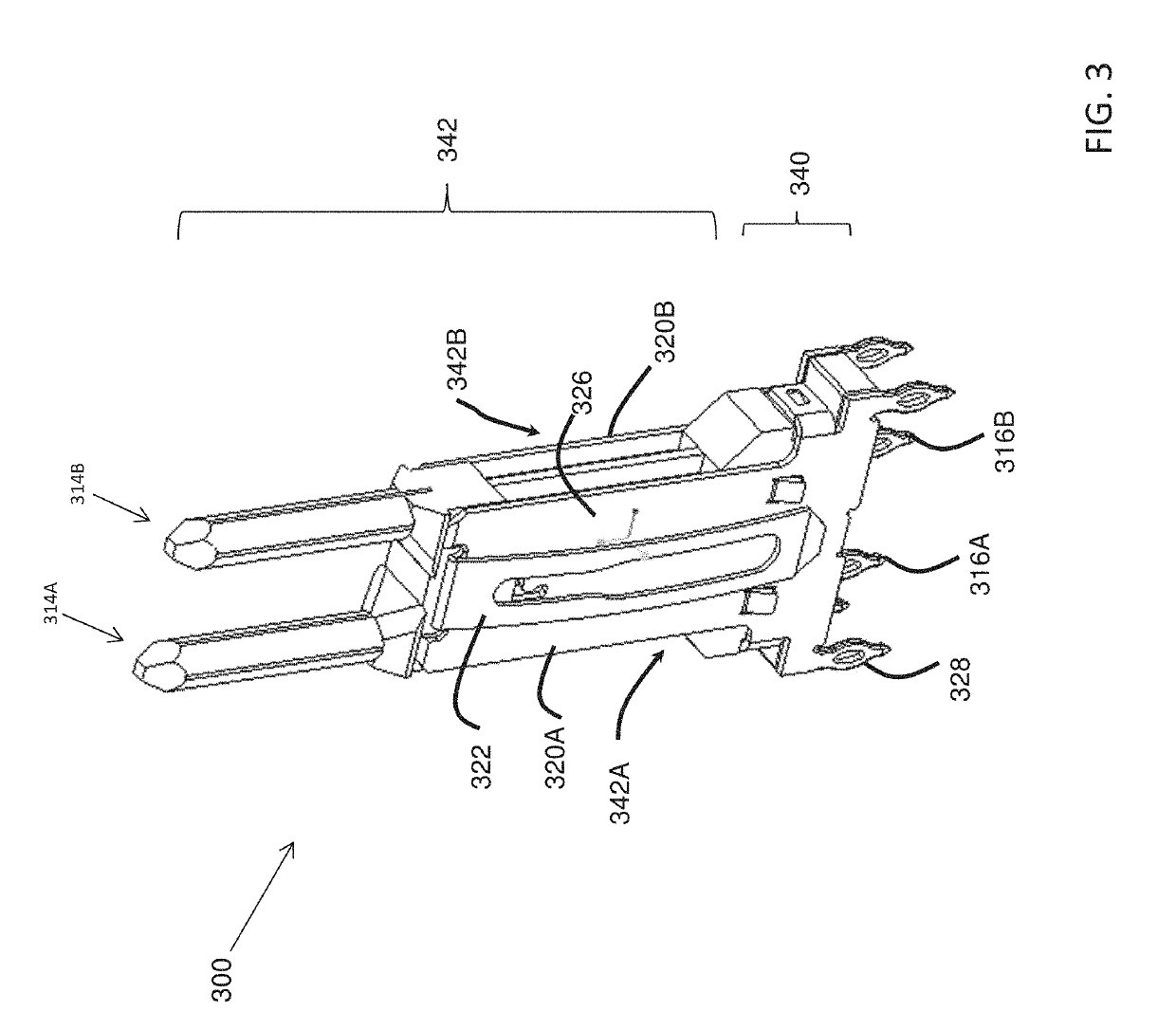

Insulative support for very high speed electrical interconnection

ActiveUS20190296496A1Reduce dielectric lossSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorDielectric loss

An electrical connector module with openings in an insulative support selectively positioned to limit dielectric loss in a signal. The connector may include a first and second conductor including first and second sides between first and second edges. An insulative support holds the first conductor adjacent the second conductor and may have at least five pedestal portions, wherein the first pedestal portion contacts the first side of the first conductor, the second pedestal portion contacts the second side of the first conductor, the third pedestal portion contacts the first side of the second conductor, the fourth pedestal portion contacts the second side of the second conductor, and at least a portion of the fifth pedestal portion is disposed between two edges of the first and second conductors. The pedestal portions may have widths less than the widths of the first and second sides of the first and second conductors.

Owner:AMPHENOL CORP

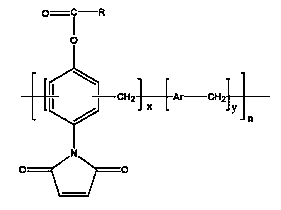

Modified nano cobalt ferrite/arylene ether nitrile dielectric composite material and preparation process thereof

The invention discloses a modified nano cobalt ferrite / arylene ether nitrile dielectric composite material which comprises arylene ether nitrile as a substrate and modified nano cobalt ferrite as packing, wherein the modified nano cobalt ferrite is of a core-shell structure with nano cobalt ferrite as a core and a high polymer or a decomposition substance of a modifier as a shell. The invention further discloses a preparation process of the modified nano cobalt ferrite / arylene ether nitrile dielectric composite material. The process comprises the following steps: putting modified nano cobalt ferrite into DMSO (Dimethylsulfoxide), adding phenolphthalein, 2,6-dichlorobenzene nitrile, anhydrous K2CO3 and methylbenzene to carry out a reaction, carrying out dilution, precipitation, purificationand drying, and carrying out hot-pressing molding, thereby obtaining a product. Due to the core-shell structure of the dielectric composite material, the compatibility of the modified nano cobalt ferrite and the arylene ether nitrile is improved, so that the dielectric constant of the material is increased; by adopting the method disclosed by the invention, the dispersibility of the modified nanocobalt ferrite in the arylene ether nitrile is improved, so that the dielectric constant of the material is further increased, and meanwhile the mechanical properties of the material are improved.

Owner:XIAN UNIV OF SCI & TECH

Polyimide adhesive film with excellent comprehensive performance as well as preparation method and application thereof

ActiveCN113248708AImprove hot melt effectSmall dielectric lossFilm/foil adhesives without carriersPolymer scienceDielectric loss

The invention relates to a polyimide adhesive film with excellent comprehensive performance as well as a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that an existing polyimide adhesive film can hardly have excellent heat resistance, good adhesive property, low dielectric constant at high frequency and low dielectric loss. The polyimide adhesive film is mainly prepared from aromatic dianhydride, aromatic diamine containing a diphenyl ether structure and diamine containing a siloxane structure. The polyimide adhesive film has excellent heat resistance, high-frequency low dielectric property and good adhesive property. The glass-transition temperature is higher than 330 DEG C, the dielectric constant (Dk) at 10 GHz is smaller than 3, the dielectric loss (Df) value is 0.003-0.006, and the peel strength after the polyimide adhesive film is in hot-pressing adhesive connection with a copper foil is larger than 10 N / cm. The application requirements of flexible printed circuit board manufacturing and interlayer bonding and insulation in multi-layer circuit board lamination wiring processing can be met. The polyimide adhesive film provided by the invention can be widely applied to the fields of high-frequency flexible printed circuit boards, high-frequency film antennas and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

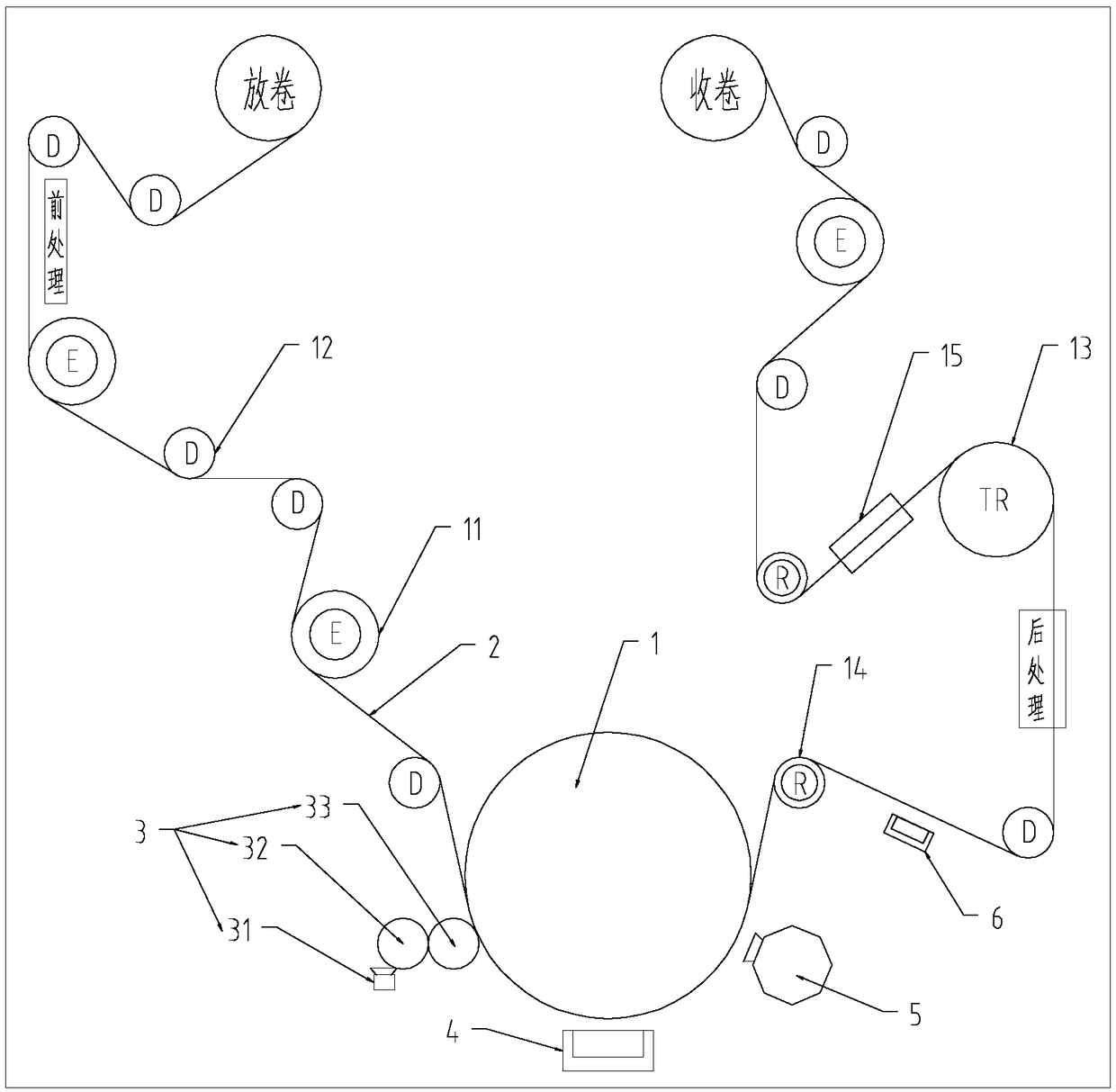

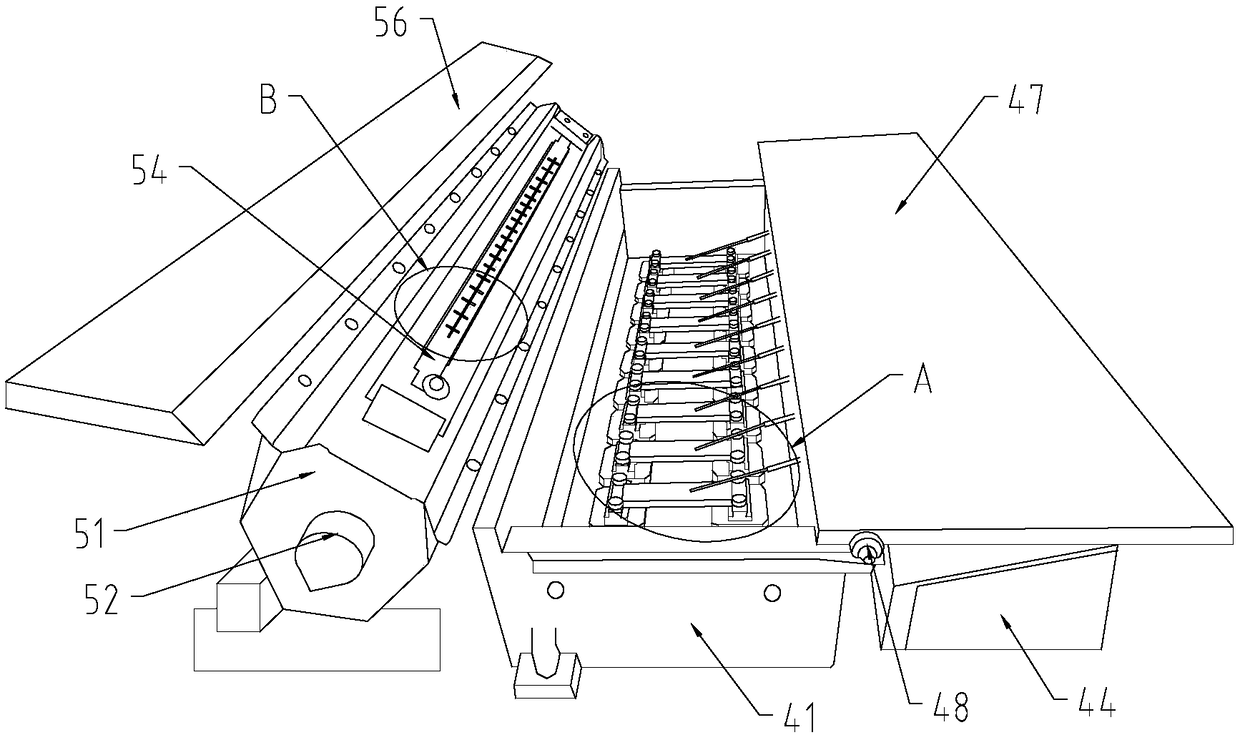

Manufacturing device and manufacturing process for metalized film for low power loss capacitor

ActiveCN108933048AReduce dielectric lossLower equivalent series resistanceFixed capacitor electrodesThin/thick film capacitorEngineeringZinc

The invention discloses a manufacturing device for a metalized film for a low power loss capacitor. The device includes a master roll, a safety film oil printing device, an aluminum evaporation deviceand a zinc evaporation device. A base film moves along the surface of the master roll. The safety film oil printing device, the aluminum evaporation device and the zinc evaporation device are arranged surrounding the surface of the master roll and along the movement direction of the base film in sequence. The invention also provides a manufacturing process for the metalized film for the low powerloss capacitor. According to the invention, safety film oil is evaporated onto a copying roll and is then transferred to a relief block pattern of a printing roll through the copying roll. The safetyfilm oil is printed on the base film through the relief block pattern. An oil layer corresponding to a blank portion of the metalized film is formed and the oil layer is uniform. At the same time, the metal edge is clear. Therefore, reduction of medium loss of the capacitor and series connection equivalent resistance is facilitated, fluctuation of capacity of the capacitor is reduced, and productperformance is improved. Moreover, the manufacturing device is simple and reasonable in structure and metal evaporation can be performed selectively based on needs.

Owner:广东迈特斐薄膜科技有限公司

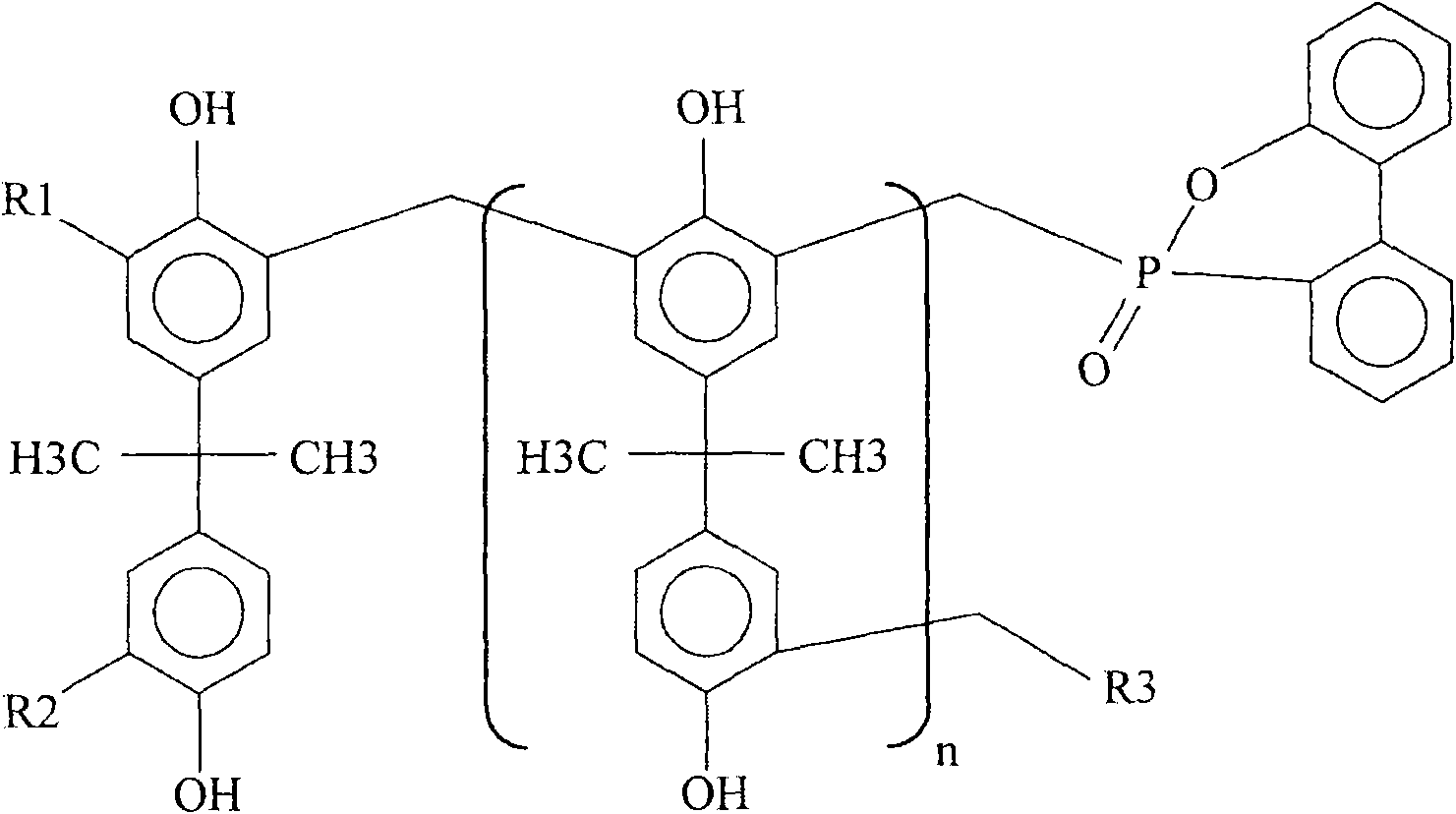

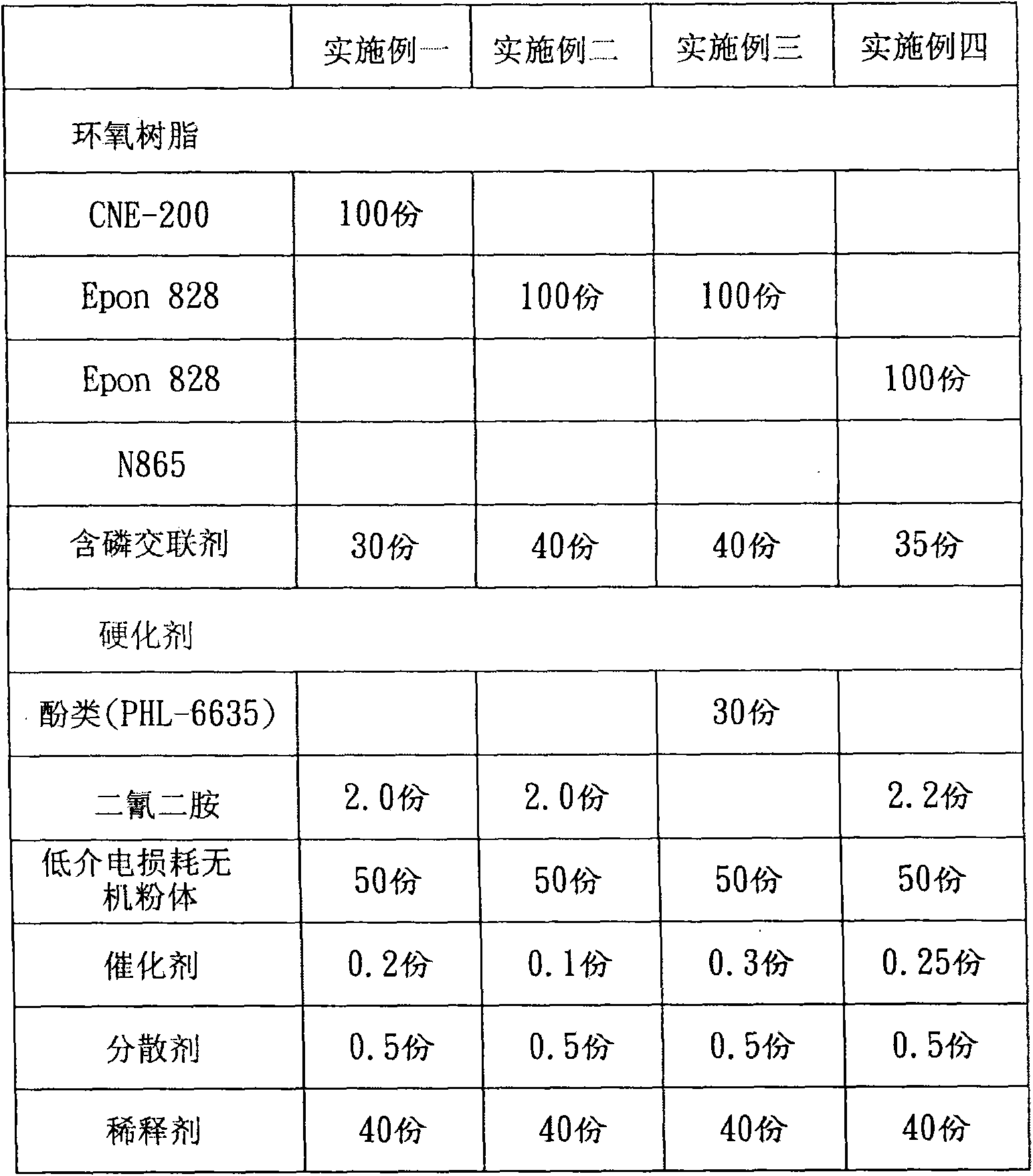

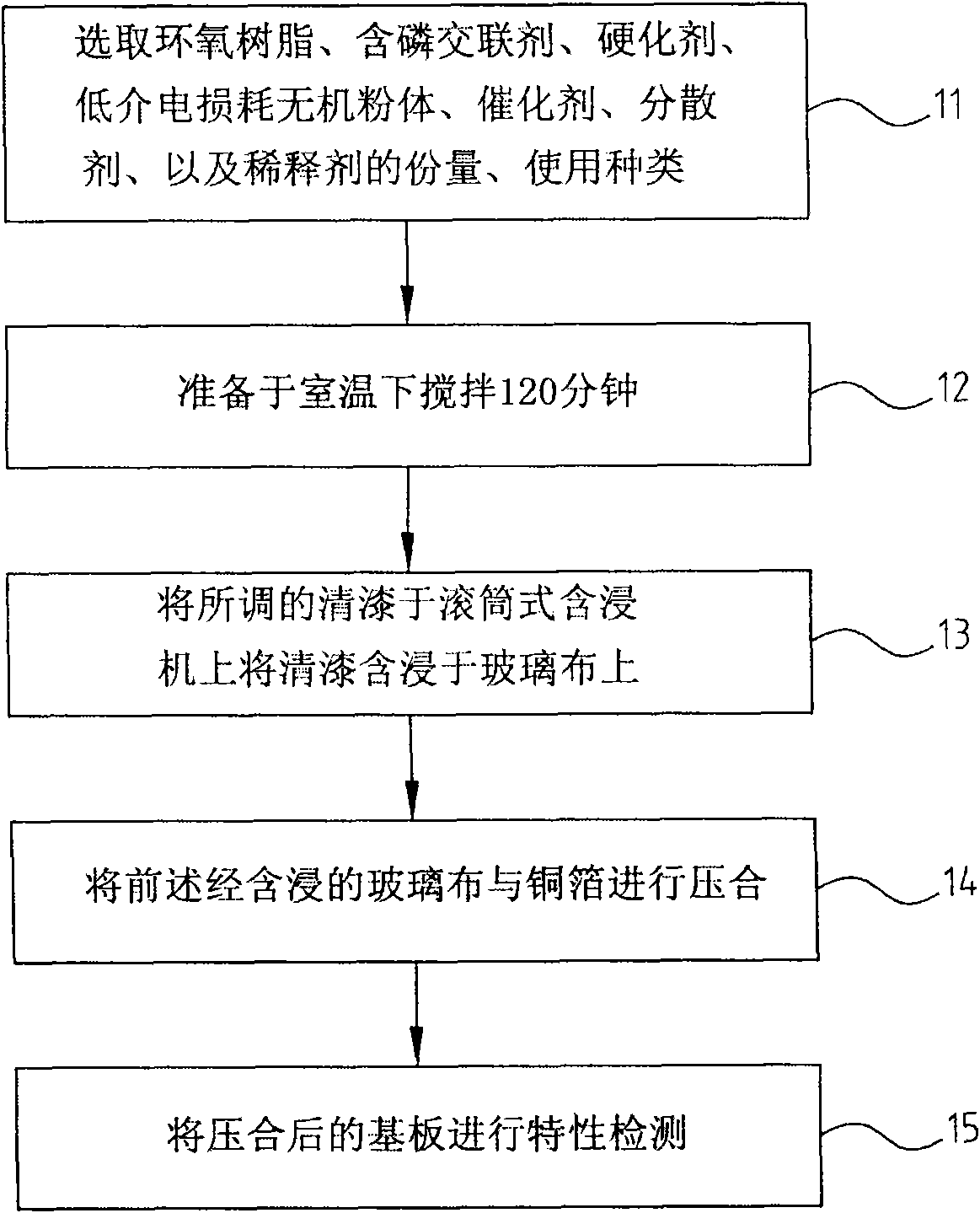

Material composition of halogen-free printed circuit board with low dielectric loss and manufacturing method thereof

InactiveCN101649106ALow dielectric constantReduce dielectric lossCircuit susbtrate materialsElectricityChemical composition

The invention discloses material composition of a halogen-free printed circuit board with low dielectric loss and a manufacturing method thereof, which are applied to the manufacturing environment ofa substrate material of the printed circuit board. The material composition of the halogen-free printed circuit board with the low dielectric loss mainly comprises a phosphor-containing phenolic resintaken as a crosslinking agent; and the crosslinking agent can make the substrate material of the printed circuit board pass a UL 94-0 flame retardant test, can also make phosphor combined with the material into a material structure to eliminate the worry of precipitation, and can be matched with a resin with low dielectric loss characteristic and inorganic powder so as to reduce the dielectric constant and the dielectric loss of the material. The material composition of the halogen-free printed circuit board with the low dielectric loss has the advantages of low dielectric loss characteristic, heat resistance and low expansibility, and can also meet the requirement of no lead solder to meet the requirements of the market and environmental protection at the same time.

Owner:TAIWAN POWDER TECH CO LTD

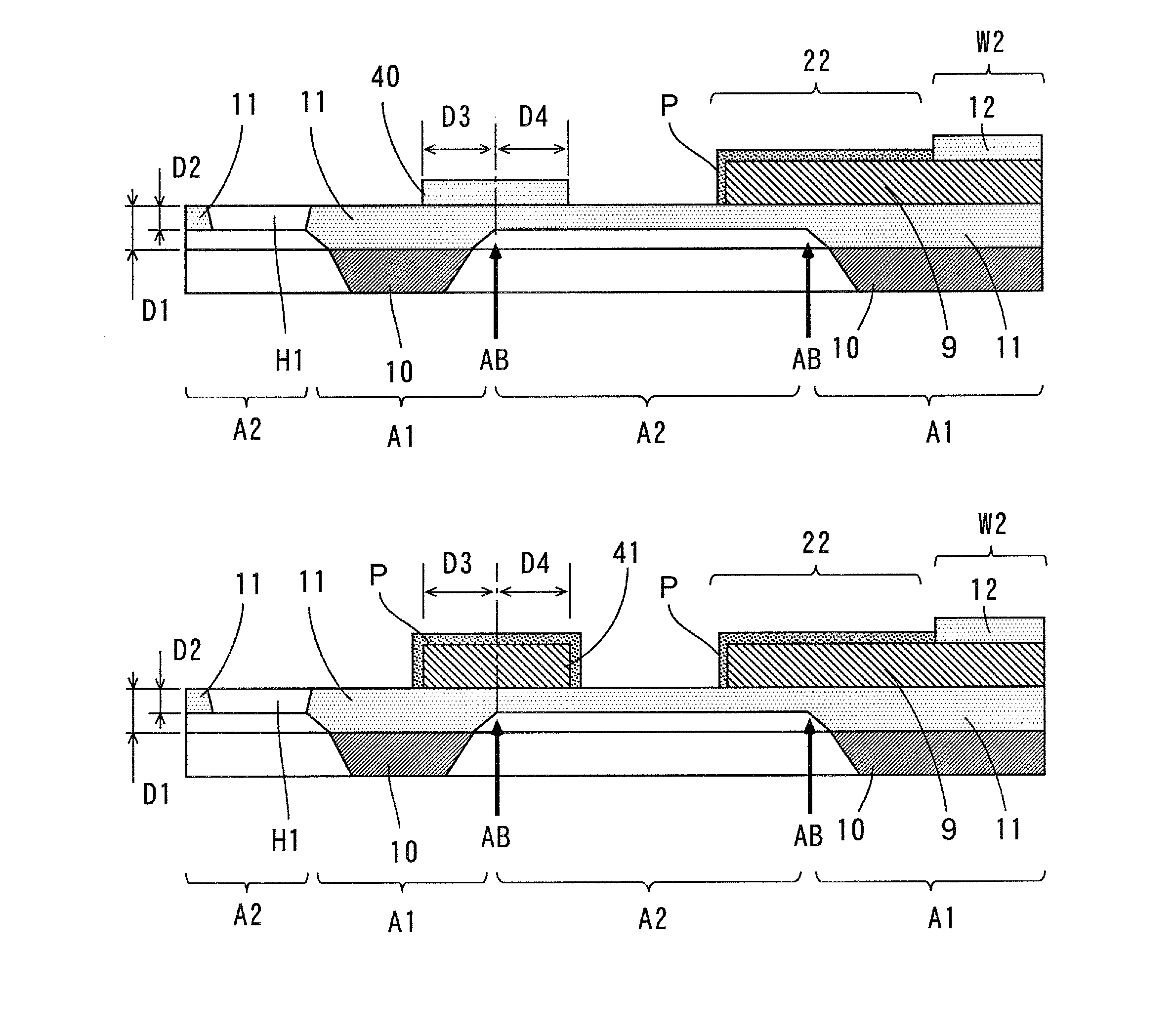

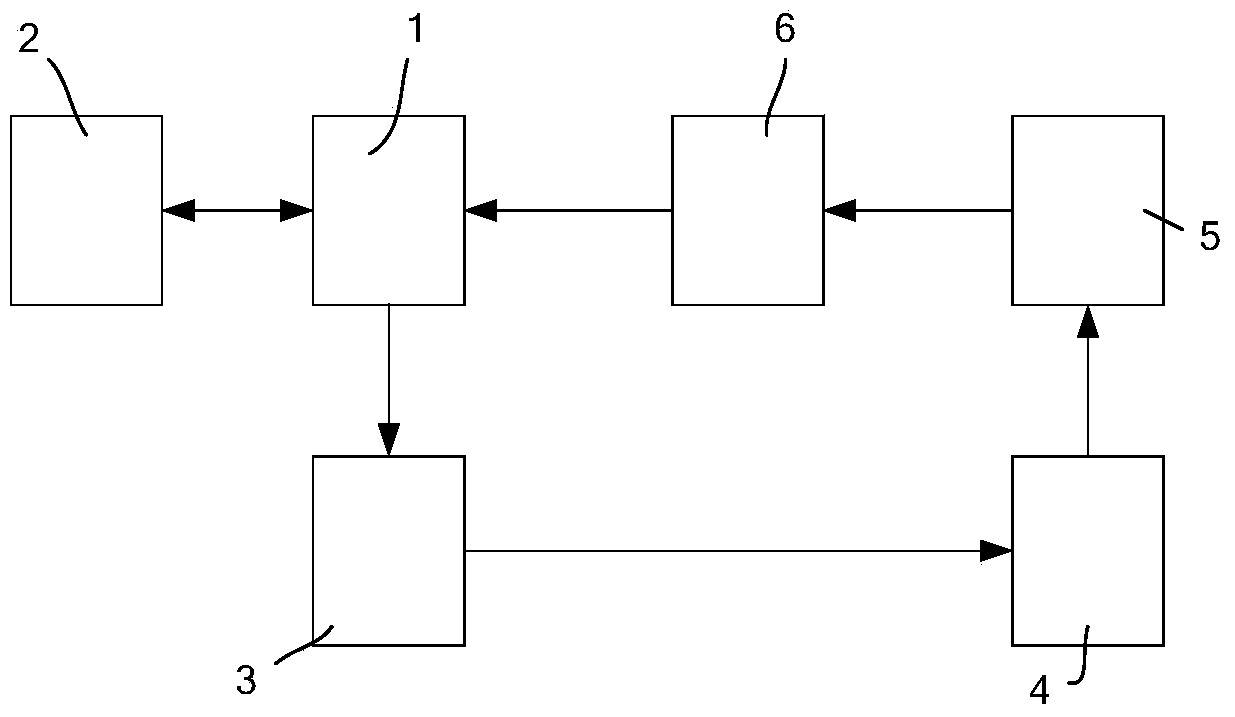

Printed circuit board and method of manufacturing the same

ActiveUS9226395B2Reduce dielectric lossAvoid damagePrinted circuit assemblingDisposition/mounting of recording headsElectrical conductorEngineering

Owner:NITTO DENKO CORP

Treatment system and method for reducing dielectric loss value of transformer oil

ActiveCN103646755AReduce dielectric lossTransportation safetyTransformers/inductances coolingFiltration circuitsDielectric lossAntioxidant

The invention discloses a treatment system for reducing the dielectric loss value of transformer oil. The system comprises a vacuum oil filter, an oil purifying tank, an oil pump, a filter, a heater and an oil dielectric loss treatment tank which are communicated. The invention further provides a treatment method for reducing the dielectric loss value of the transformer oil. The method comprises the following steps: treating the transformer oil through the system; continuously circulating for 8 to 10 hours at each time; operating one time per day within 7 days before treating the transformer oil, then operating for one time every other 1 day, and operating for 3 to 4 times at intervals; after circulation treatment on the transformer oil is completed, adding an antioxidant into the transformer oil. According to the invention, dielectric loss pollutants in the transformer oil are absorbed by the oil dielectric loss treatment tank, and long-time and interval operation of the whole circulating system is performed, so that the dielectric loss pollutants in an oil conveying pipeline are adsorbed and removed, the dielectric loss value of the transformer oil is reduced, and the transformer oil is conveyed into the transformer from the oil purifying tank safely and reliably.

Owner:ZHONGSHAN KAIXUAN VACUUM SCI & TECH CO LTD +1

Piezoelectric transducers

ActiveUS20180015505A1High resistivityReduce dielectric lossSubsonic/sonic/ultrasonic wave measurementUsing electrical meansTransducerEngineering

A piezoelectric transducer comprises a piezoelectric element operable to transduce mechanical movement of the piezoelectric element to an electrical signal and to transduce an electrical signal in the piezoelectric element to a mechanical movement thereof, wherein the piezoelectric transducer is operable to transduce above a temperature of 200° C.

Owner:IONIX ADVANCED TECH

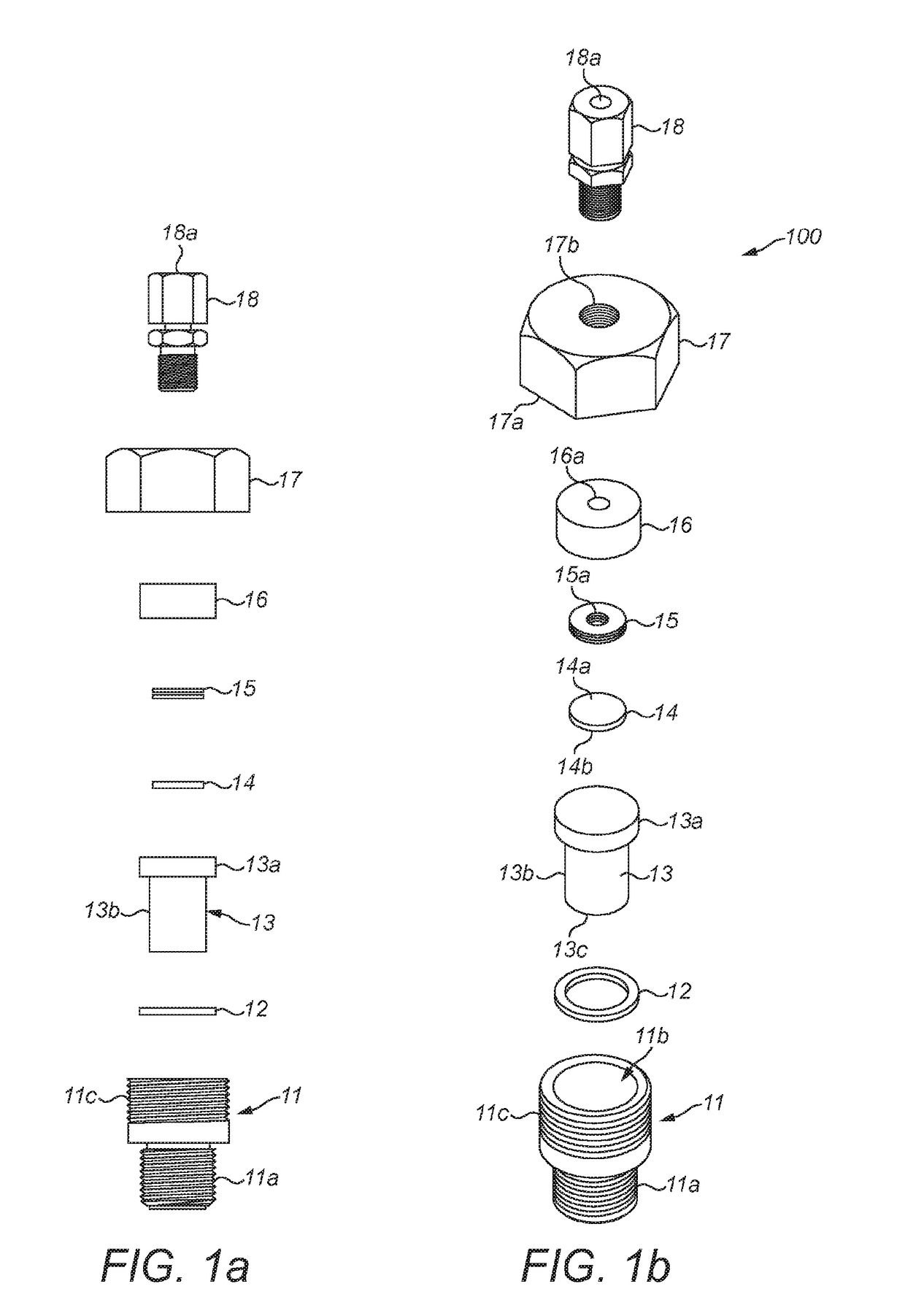

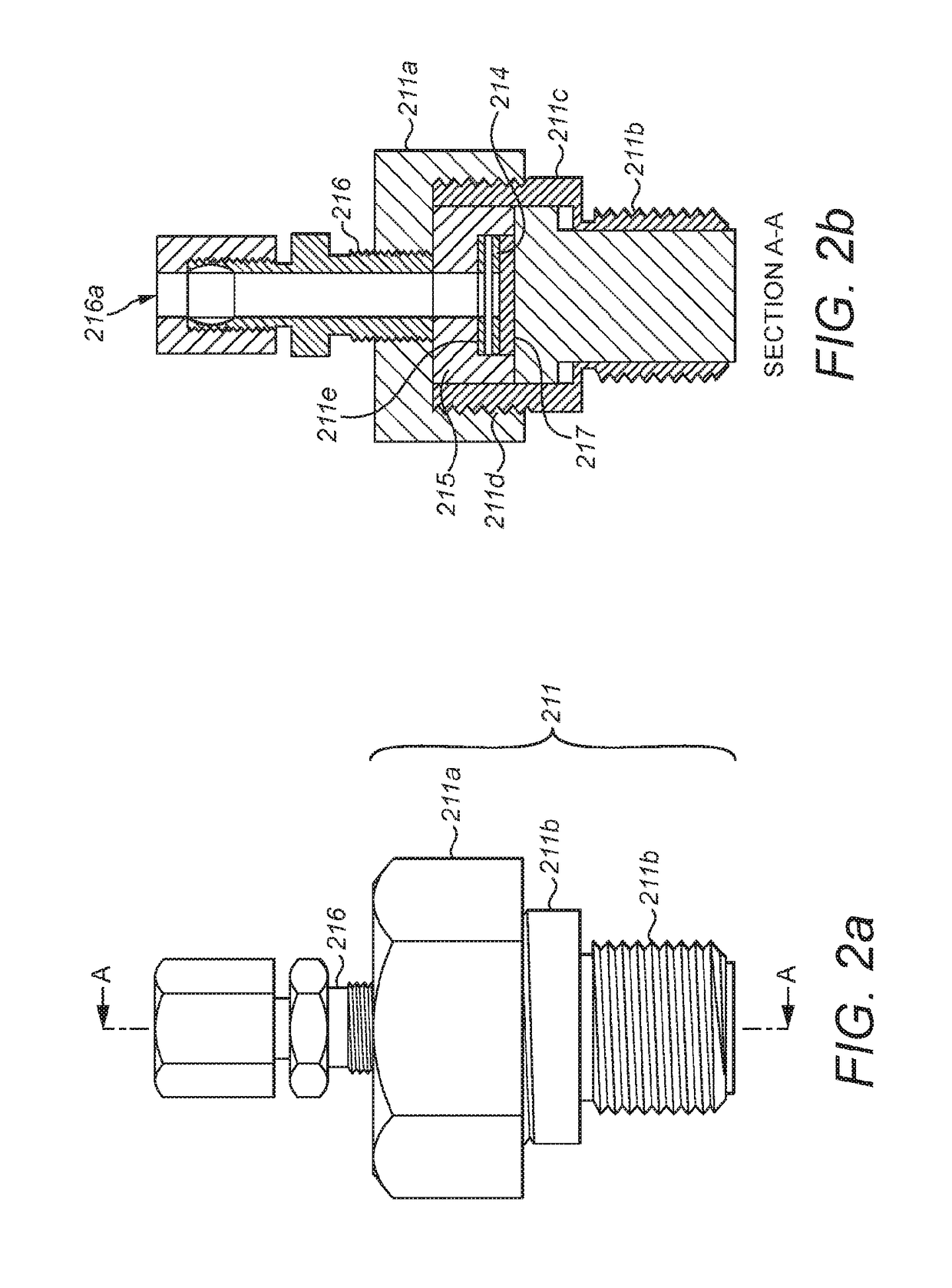

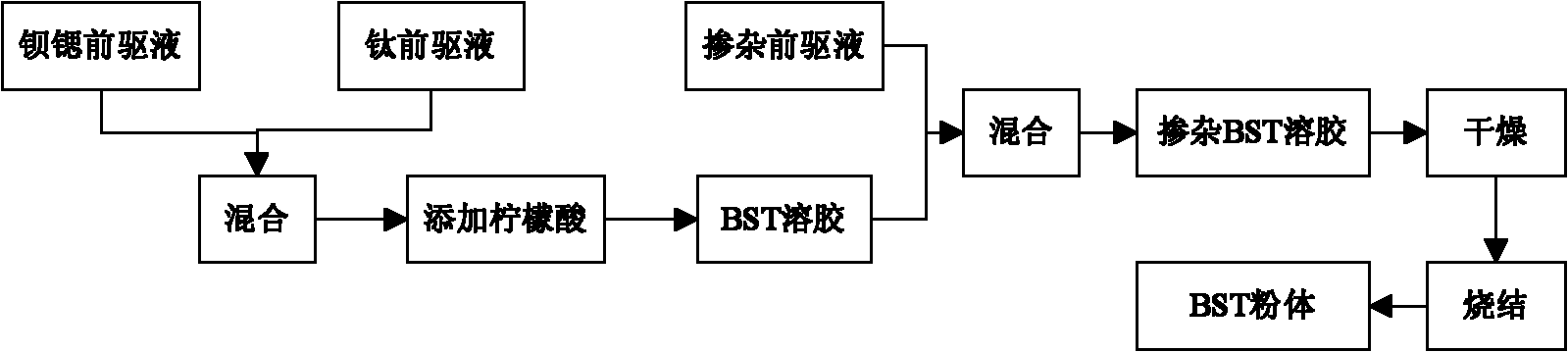

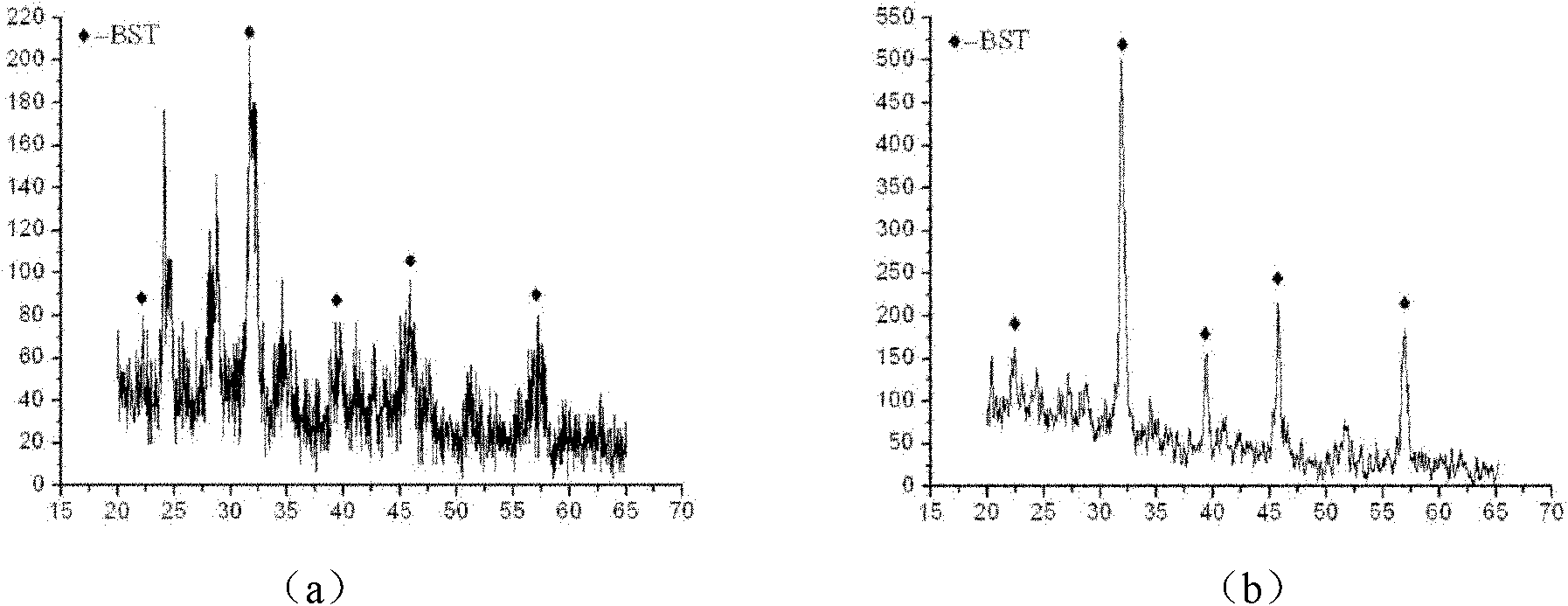

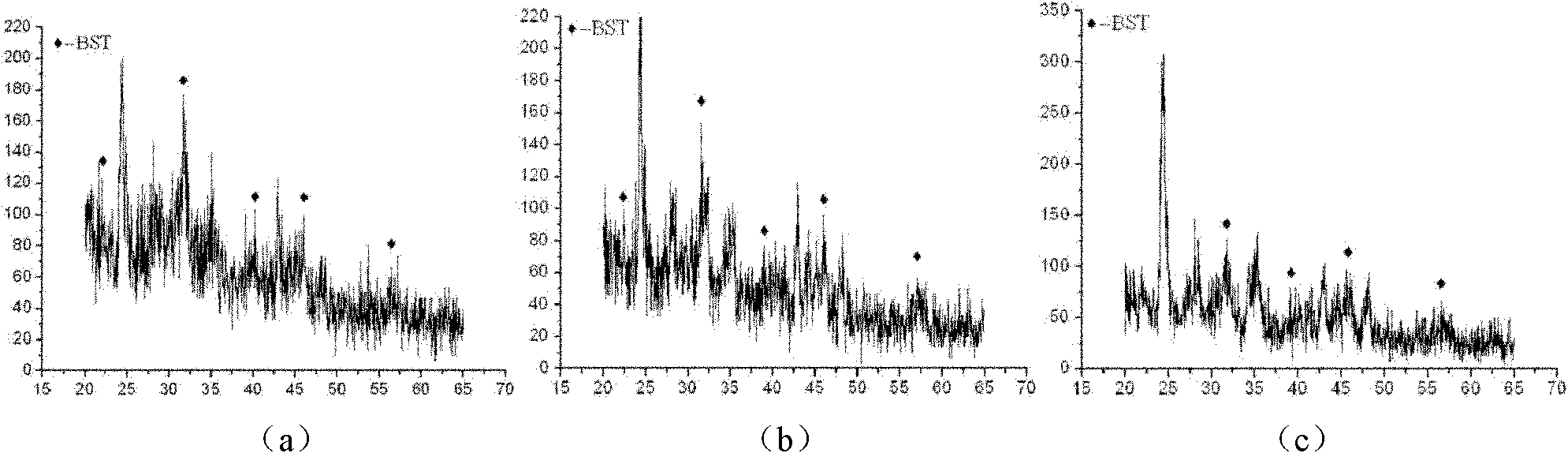

Method of preparing two-component co-doped BST (Barium Strontium Titanate) micro-nano powder

The invention provides a method of preparing a two-component co-doped BST (Barium Strontium Titanate) micro-nano powder by aiming at the technical problem of poor dielectric property caused by impure phases in the BST powder prepared with a common Sol-gel method, belonging to the technical field of functional materials. The method comprises the following steps of: carrying out two-component co-doping on BST and adding citric acid in the process of preparing BST collosol so as to greatly improve the stability and the uniformity of the two-component co-doped BST collosol in the forming process; thus, the collosol with higher purity is obtained, and the BST micro-nano powder without containing impure phases is obtained after the collosol is sintered so that the dielectric property is greatly improved (the dielectric constant is from 150 to 1200, the tuning rate is from 0% to 65%, the dielectric loss is from 0.0003 to 0.006, and the dielectric temperature coefficient is from 0.0002 to 0.001 / K). The two-component co-doped BST micro-nano powder can be applied to microwave tuning devices, and the method has the advantages of convenience, rapidness, low cost and high efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com