Monodisperse hollow mesoporous silicon oxide microsphere material and double-surfactant induced assembly preparation method thereof

A mesoporous silica and surfactant technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problem that it is difficult to prepare monodisperse mesoporous silica microsphere materials, achieve good monodispersity, and can The effect of strong control and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

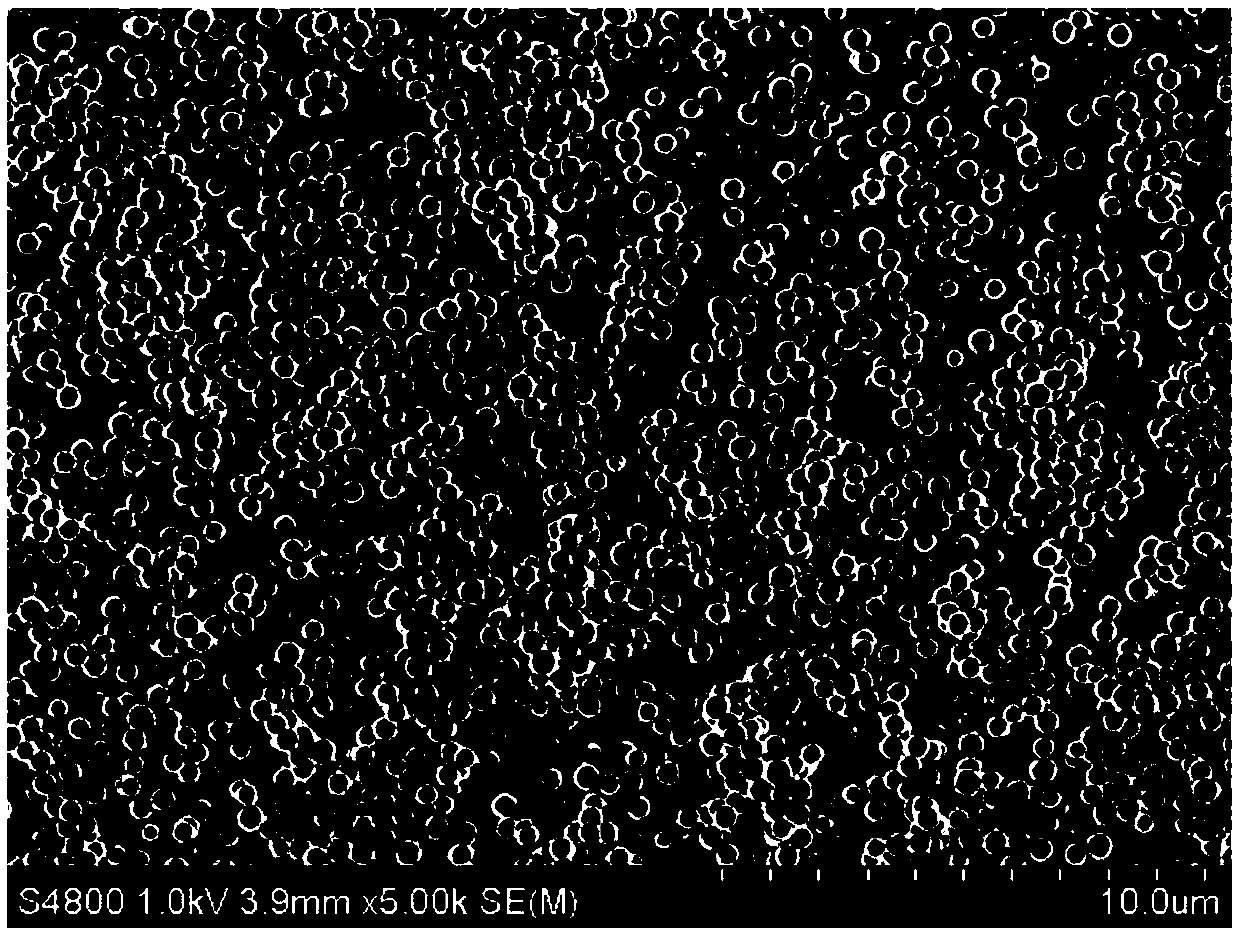

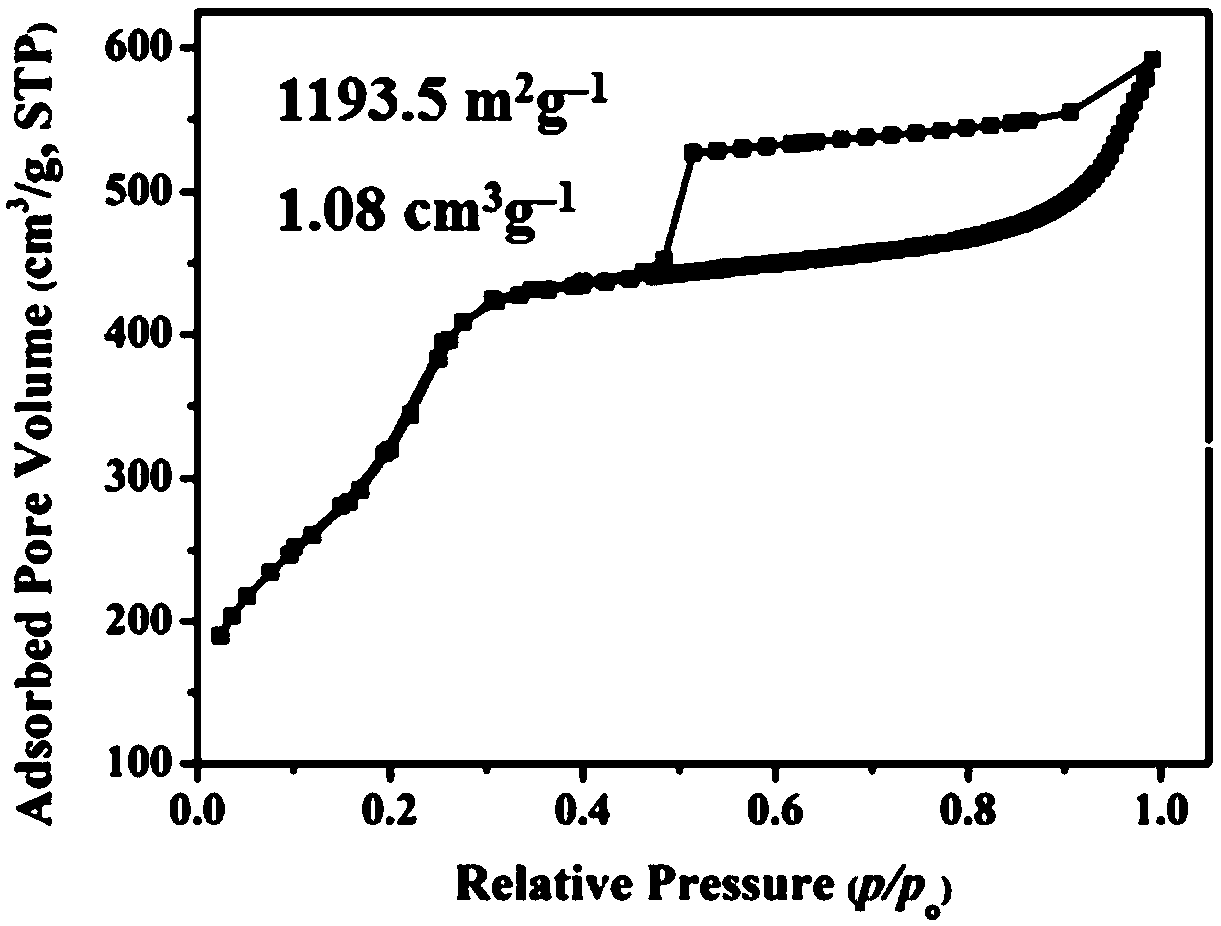

[0032] Dissolve a certain amount of Pluronic F127 and CTAB with 200ml of ethanol and water mixed solution under stirring condition, add 10ml of tetraethyl silicate deionized water after dissolving, and continue mechanical stirring. After stirring for 5 minutes, 5ml of ammonia water was added dropwise to the above mixed solution, and stirring was continued for 10 hours. The obtained white gel mixed solution was centrifuged at 12000rpm for 10 minutes to separate the white gel precipitate product, then washed with ethanol three times, and then washed with water three times, and the obtained white precipitate was dried in air at 60°C for 12 hours, Dispersed in 100ml of water, heat-treated in solvent at 150°C for 6 hours, and then calcined at 600°C for 4 hours, the mesoporous silica microspheres with a diameter of 500nm and a monodisperse hollow structure can be obtained. Its shape and properties are shown in Figure 1-Figure 5 shown. What is prepared is a silica microsphere mate...

Embodiment 2

[0034] Dissolve a certain amount of Pluronic F127 and dodecyltrimethylammonium chloride with 200ml of ethanol and water mixed solution with stirring, add 10ml of tetraethyl silicate deionized water after dissolution, and continue mechanical stirring. After stirring for 5 minutes, 5ml of ammonia water was added dropwise to the above mixed solution, and stirring was continued for 10 hours. The obtained white gel mixed solution was centrifuged at 12000rpm for 10 minutes to separate the white gel precipitate product, then washed with ethanol three times, and then washed with water three times, and the obtained white precipitate was dried in air at 60°C for 12 hours, Dispersed in 100ml of water, heat-treated in solvent at 150°C for 6 hours, and then calcined at 600°C for 4 hours, the mesoporous silica microspheres with a diameter of 550nm and a monodisperse hollow structure can be obtained.

Embodiment 3

[0036] Dissolve a certain amount of Pluronic F127 and CTAB with 200ml of ethanol and water mixed solution under stirring condition, add 10ml of tetraethyl silicate deionized water after dissolving, and continue mechanical stirring. Compared with Example 1, the ratio of ethanol and water in the mixed solution was changed, and after stirring for 5 minutes, 5ml of ammonia water was added dropwise to the above mixed solution, and the stirring was continued for 10 hours. The obtained white gel mixed solution was centrifuged at 12000rpm for 10 minutes to separate the white gel precipitate product, then washed with ethanol three times, and then washed with water three times, and the obtained white precipitate was dried in air at 60°C for 12 hours, Dispersed into 100ml of water, heat-treated in solvent at 150°C for 6 hours, and then calcined at 600°C for 4 hours, the mesoporous silica microspheres with a diameter of 300nm and a monodisperse hollow structure can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com