Monodispersive porous crystal titanium oxide nanosphere with size smaller than 100 nm and preparation method thereof

A titanium oxide, monodisperse technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problem of difficult to prepare small-sized monodisperse porous titanium oxide nanosphere materials, and achieve good cycle stability. The effect of stability, uniform particle size and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

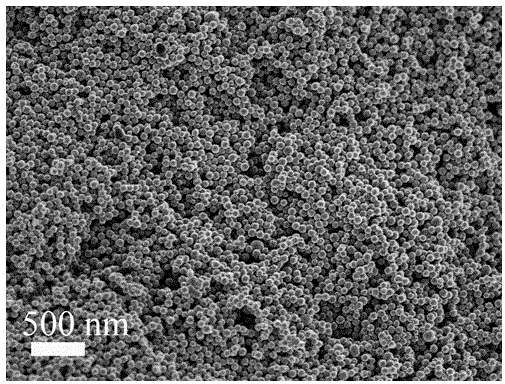

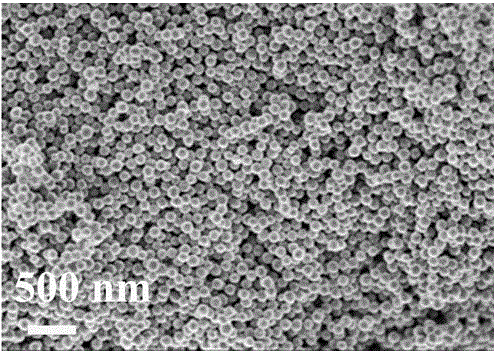

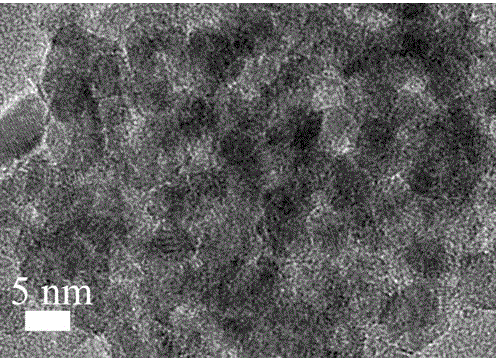

[0031]Dissolve 1.6g of Pluronic F127 and 0.8g of n-dodecylamine in 150ml of ethanol, add 15ml of deionized water after dissolution, and then stir magnetically. After stirring for half an hour, 0.8 g of tetrabutyl titanate was slowly introduced into the above solution, and after stirring for 1 hour, it was left to stand for 12 hours. Centrifuge the white gel precipitate formed in the solution at 12000rpm for 10 minutes to separate the white gel precipitate, then wash it with ethanol three times, then wash it with water three times, dry the white precipitate in the air at 60°C for 12 hours, and then disperse Solvent heat treatment at 150° C. for 12 hours in 50 ml of ethanol and 25 ml of water mixed solvent, and then calcined at 500° C. for 4 hours to obtain monodisperse porous titanium oxide nanospheres with a diameter of 40 nm. Its shape and properties are shown in figure 1 , Figure 3-Figure 8 shown. The prepared titanium oxide nanomaterial has a spherical shape, and the di...

Embodiment 2

[0033] Dissolve 1.6g of Pluronic F127 and 0.8g of n-dodecylamine in 150ml of ethanol, add 10ml of deionized water after dissolution, and then stir magnetically. After stirring for half an hour, 0.8 g of tetrabutyl titanate was slowly introduced into the above solution, and after stirring for 1 hour, it was left to stand for 12 hours. The white gel precipitate formed in the solution was centrifuged at 12000rpm for 10 minutes to separate the white gel, then washed with ethanol three times, and then washed with water three times, and the obtained white precipitate was dried in the air at 60°C for 12 hours, and dispersed in Solvent heat treatment at 150°C for 12 hours in 50ml of ethanol and 25ml of water mixed solvent, and after calcination at 500°C for 4 hours, monodisperse porous titanium oxide nanospheres with a diameter of 90nm can be obtained.

Embodiment 3

[0035] Dissolve 1.6g of Pluronic F127 and 0.8g of n-dodecylamine in 150ml of isopropanol. After dissolving, add 15ml of deionized water. After stirring for half an hour, slowly introduce 0.8g of tetrabutyl titanate into the above solution. After stirring for 1 hour, statically Leave for 12 hours. The white gel precipitate formed in the solution was centrifuged at 12000rpm for 10 minutes to separate the white gel, then washed with ethanol three times, and then washed with water three times, and the obtained white precipitate was dried in the air at 60°C for 12 hours, and dispersed in Solvent heat treatment at 150°C for 12 hours in 50ml of ethanol and 25ml of water mixed solvent, and after calcination at 500°C for 4 hours, monodisperse porous titanium oxide nanospheres with a diameter of about 40nm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com