Method for cooling and dedusting fluidized bed gasified raw coal gas

A kind of crude gas, coal gasification technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

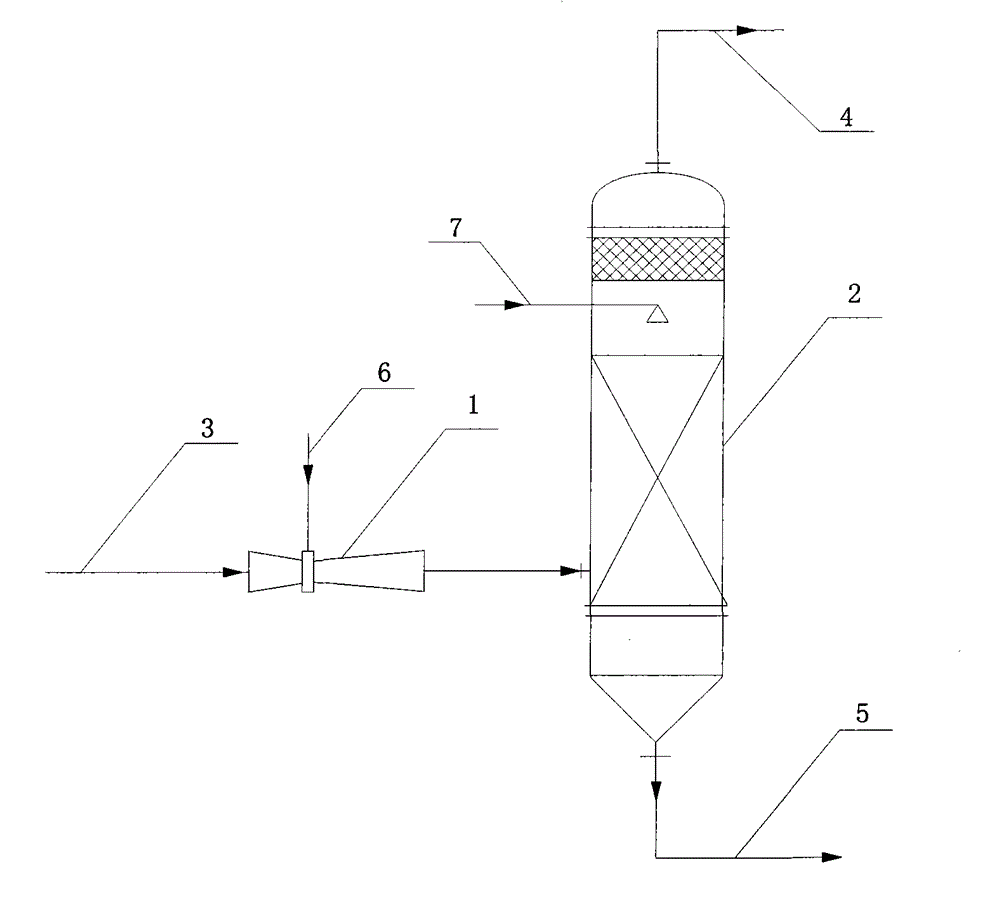

Image

Examples

Embodiment 1

[0018] The temperature is 180°C and the dust content is 3g / Nm 3 , the water vapor content is 15%, and the gas with a pressure of 0.4Mpa is pretreated by Venturi, and the amount of water injected into Venturi is 0.12kg / Nm 3 , this amount of water makes the temperature of the gas reach the dew point temperature of the water, so that the steam is partially condensed to form mist droplets, which are much smaller than the droplets formed by spraying water, and the mist droplets formed by the condensation of the steam itself are very small, which can make the dust agglomerate and grow , and then enter the packed tower for washing and cooling, the gas temperature drops to 40°C, and the dust content is less than 5mg / Nm 3 .

Embodiment 2

[0020] The temperature is 200°C and the dust content is 10g / Nm 3 , the water vapor content is 25%, and the gas with a pressure of 0.6Mpa is pretreated by Venturi, and the amount of water injected into Venturi is 0.3kg / Nm 3 , this amount of water makes the temperature of the gas reach the dew point temperature of the water, so that the steam is partially condensed to form mist droplets, which are much smaller than the droplets formed by spraying water, and the mist droplets formed by the condensation of the steam itself are very small, which can make the dust agglomerate and grow , and then enter the packed tower for washing and cooling, the gas temperature drops to 40°C, and the dust content is less than 5mg / Nm 3 .

Embodiment 3

[0022] The temperature is 250°C and the dust content is 20g / Nm 3 , the water vapor content is 35%, and the gas with a pressure of 2.5Mpa is pretreated by Venturi, and the amount of water injected into Venturi is 0.5kg / Nm 3 , this amount of water makes the temperature of the gas reach the dew point temperature of the water, so that the steam is partially condensed to form mist droplets, which are much smaller than the droplets formed by spraying water, and the mist droplets formed by the condensation of the steam itself are very small, which can make the dust agglomerate and grow , and then enter the packed tower for washing and cooling, the gas temperature drops to 40°C, and the dust content is less than 5mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com