Prepreg and metal foil substrate

A semi-cured film and metal foil technology, which is applied in the field of metal foil laminates and metal foil multilayer laminates, can solve environmental pollution and other problems, and achieve reduced dielectric constant and dielectric loss, low hygroscopicity, The effect of increasing hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention discloses a prepreg, which includes a reinforcing material and a thermosetting resin composition, wherein the reinforcing material can be glass fiber cloth; the thermosetting resin composition includes epoxy resin, aromatic ester hardener and flame retardant compound.

[0070] The epoxy resin (epoxy resin) can be bisphenol A (bisphenol-A) epoxy resin, bisphenol F (bisphenol-F) epoxy resin, bisphenol S (bisphenol-S) epoxy resin, phenolic ( phenol novolac) epoxy resin, bisphenol-A novolac epoxy resin, o-cresol novolac epoxy resin, trifunctional epoxy resin, tetrafunctional epoxy resin Epoxy resin, multifunctional epoxy resin, dicyclopendiene epoxy resin (Dicyclopendieneepoxy resin; DCPD), p-xylene epoxy resin (P-xylene epoxy resin), phosphorus epoxy resin, naphthalene Epoxy resin (Naphthalene epoxy resin), benzopyran type epoxy resin.

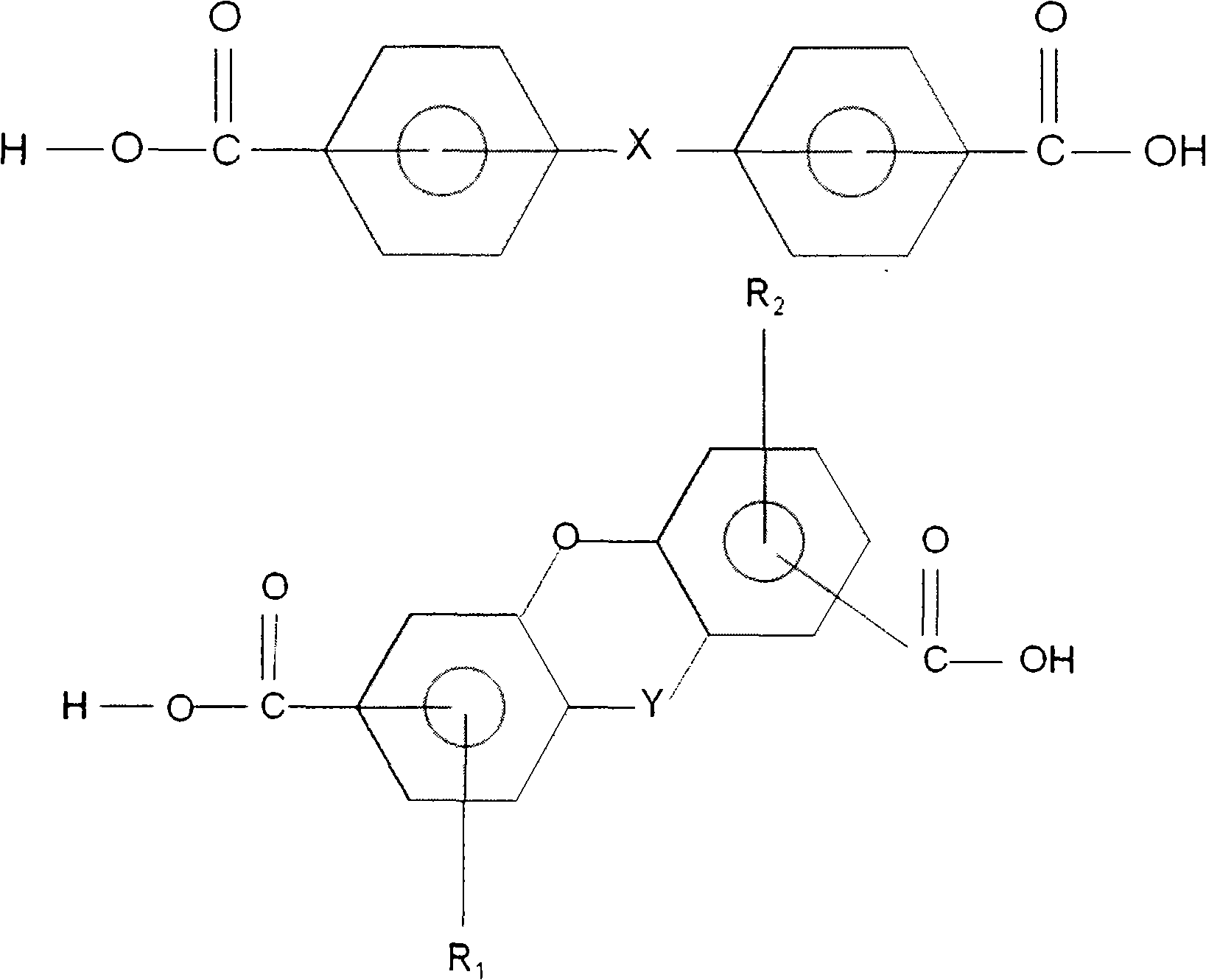

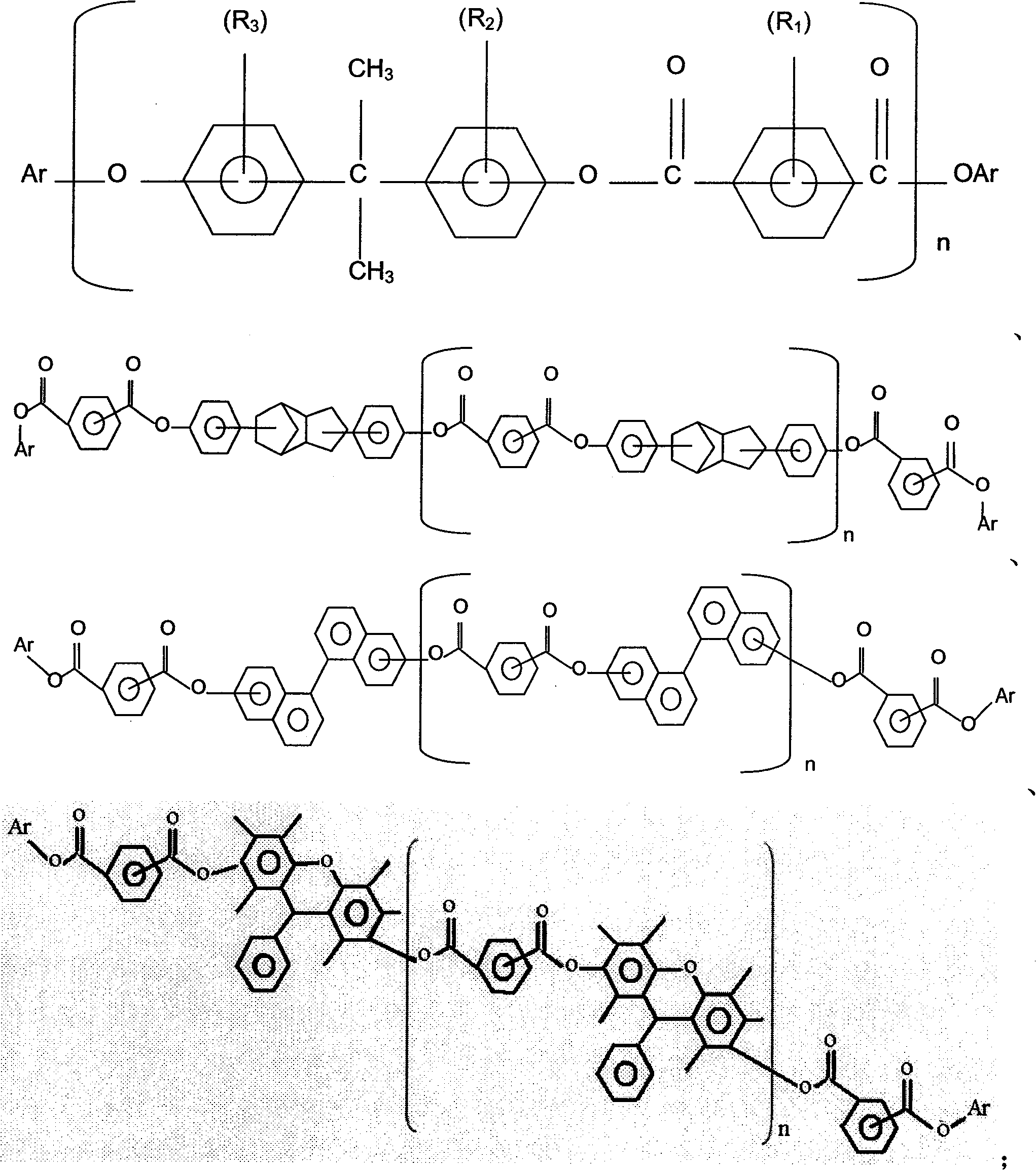

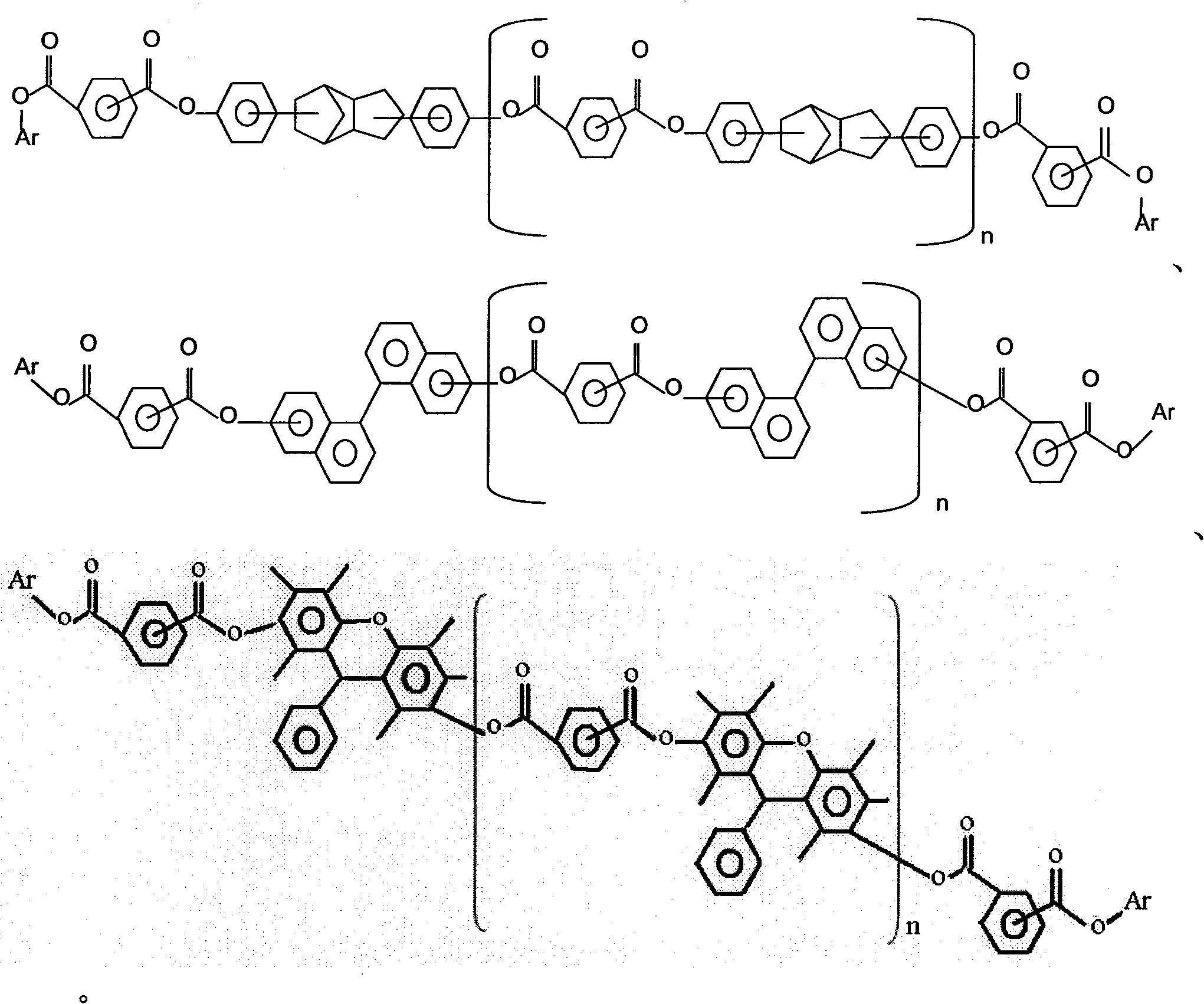

[0071] The aromatic ester hardener has at least one of the following structural formulas:

[0072]

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com