Low dielectric constant polyhedral oligomeric silsesquioxane (POSS)/ epoxy resin hybrid material and preparation method

A technology of epoxy resin and hybrid materials, which is applied in the field of organic polymer materials, can solve the problems of not being able to meet the industrial requirements of high-performance electronic packaging technology and general dielectric properties, and achieve the reduction of dielectric coefficient, excellent dielectric loss, Dielectric Loss Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

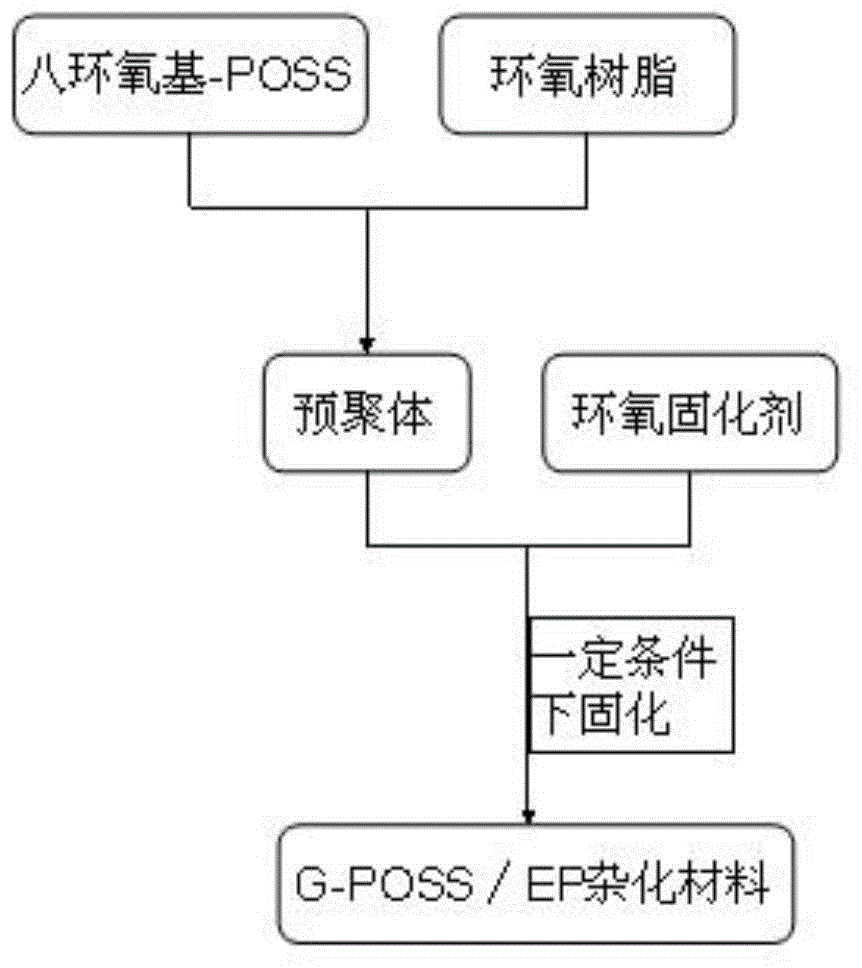

Method used

Image

Examples

Embodiment 1

[0025] Example 1: ①. Dissolve 100 parts of bisphenol A epoxy resin and 0 parts of octaepoxy polysilsesquioxane in acetone, stir and blend evenly for 1 to 24 hours, and heat at 80°C Under the pre-reaction, make a homogeneous hybrid resin stock solution A; ②, add an equivalent of 12.43 parts of curing agent and non-essential additives to A solution, stir evenly, and vacuumize at 60°C to remove air bubbles for 20-30min, Obtain prepolymer B; ③. Slowly pour the prepolymer B in step ② into the preheated mold, put it into the oven at 50℃ / 2h+70℃ / 3h+80℃ / 1h for cross-linking and solidification, and cool with the furnace After demoulding, post-treat at 80°C for 4-6 hours to obtain the desired G-POSS / EP nano-hybrid material, and its properties are shown in Table 1.

Embodiment 2

[0026] Example 2: ① Dissolve 95 parts of bisphenol-A epoxy resin and 5 parts of octaepoxy polysilsesquioxane in acetone by mass, stir and blend evenly for 1 to 24 hours, and heat at 80°C Under the pre-reaction, make a homogeneous hybrid resin stock solution A; ②, add an equivalent of 12.54 parts of curing agent and non-essential additives to A solution, stir evenly, vacuumize at 60°C to remove air bubbles for 20-30min, Obtain prepolymer B; ③. Slowly pour the prepolymer B in step ② into the preheated mold, put it into the oven at 50℃ / 2h+70℃ / 3h+80℃ / 1h for cross-linking and solidification, and cool with the furnace After demoulding, post-treat at 80°C for 4-6 hours to obtain the desired G-POSS / EP nano-hybrid material, and its properties are shown in Table 1.

Embodiment 3

[0027] Example 3: ① Dissolve 90 parts of bisphenol-A epoxy resin and 10 parts of octaepoxy polysilsesquioxane in acetone, stir and blend evenly for 1 to 24 hours, and heat at 80°C Pre-react to make a homogeneous hybrid resin stock solution A; ② Add 12.64 parts equivalent of curing agent and non-essential additives to liquid A, stir evenly, vacuumize at 60°C to remove air bubbles for 20-30min, Obtain prepolymer B; ③. Slowly pour the prepolymer B in step ② into the preheated mold, put it into the oven at 50℃ / 2h+70℃ / 3h+80℃ / 1h for cross-linking and solidification, and cool with the furnace After demoulding, post-treat at 80°C for 4-6 hours to obtain the desired G-POSS / EP nano-hybrid material, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com