Method of preparing two-component co-doped BST (Barium Strontium Titanate) micro-nano powder

A technology of micro-nano powder and precursor is applied in the field of preparation of BST micro-nano powder, which can solve the problem that BST micro-nano powder with full perovskite structure cannot be obtained, the stability of sol is low, and uniform stability cannot be obtained. Pure gel and other problems, to achieve the effect of reducing dielectric loss and dielectric temperature coefficient, improving tuning rate and dielectric strength, reducing capacitance and dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

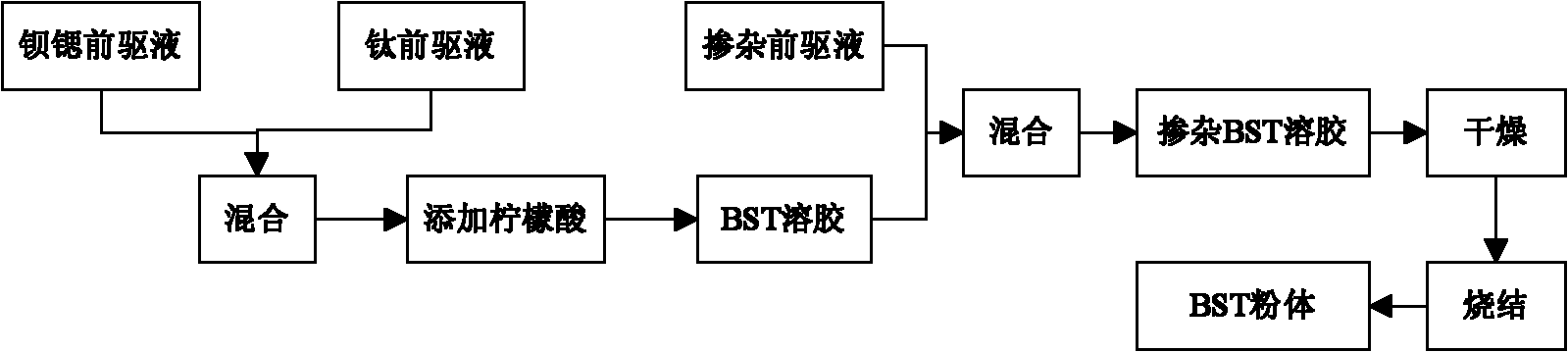

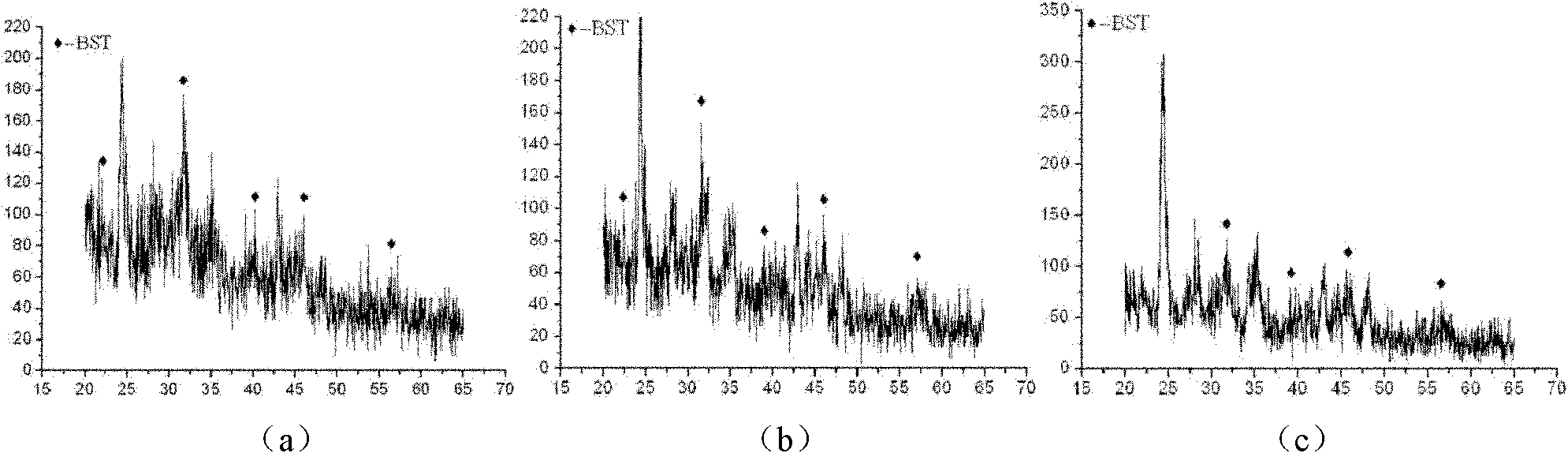

[0035] A preparation method of binary co-doped BST micro-nano powder, comprising the following steps:

[0036] Step 1: preparing BST sol;

[0037]The precursors of Ba and Sr are dissolved in hot glacial acetic acid to form a barium strontium precursor solution, and butyl titanate is mixed with acetylacetone to form a titanium precursor solution, then the barium strontium precursor solution and the titanium precursor solution are mixed, and the equivalent of Ti is added at the same time 0.25-1.25% citric acid in molar dosage, then use glacial acetic acid to adjust the pH value of the mixed solution to between 3-4, and finally use ethylene glycol methyl ether to obtain 0.2-0.4M BST sol, in which Ba, Sr and The molar ratio of Ti is x: (1-x): (1+y), 0<x<1, 0≤y≤0.25; the precursors of Ba and Sr are acetate or nitrate of Ba and Sr ; The amount of acetylacetone is 1.5 to 2.5 times the molar weight of butyl titanate;

[0038] Step 2: Prepare Mn, Ce or Y doped precursors respectively...

Embodiment 1

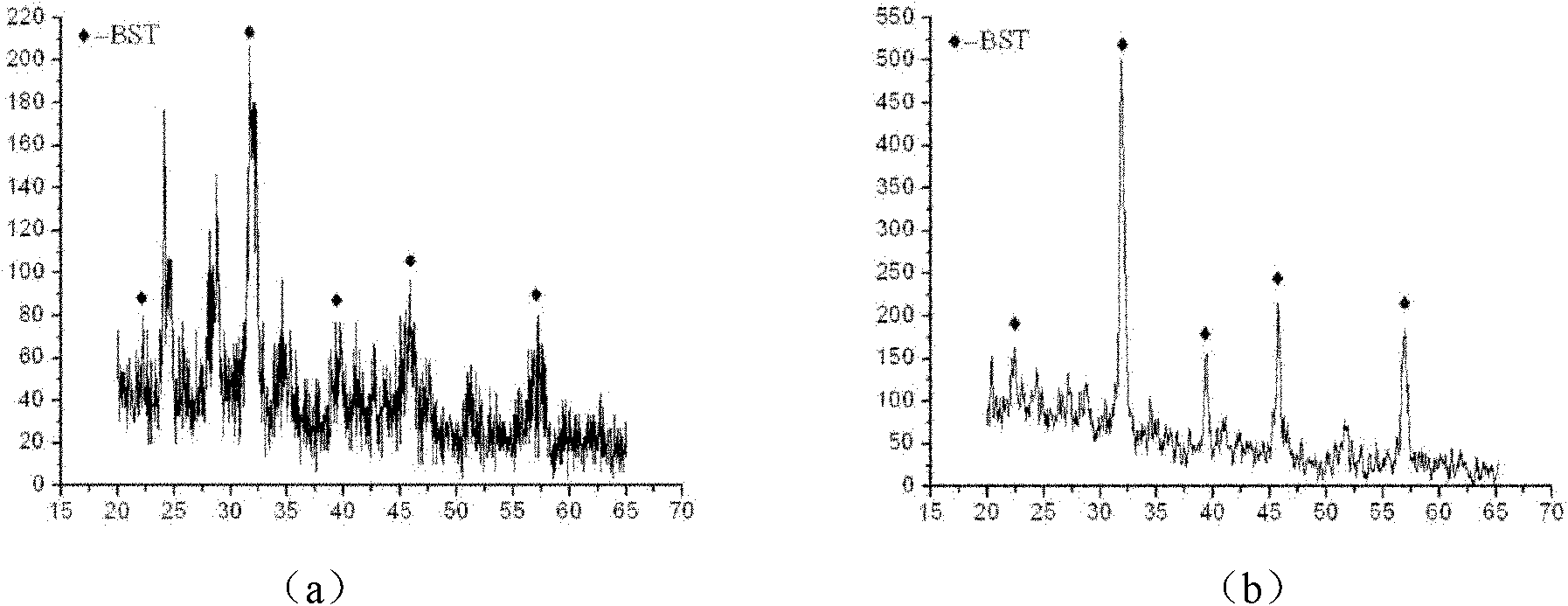

[0043] Embodiment 1: do not add citric acid Ba 0.6 Sr 0.4 TiO 3 Preparation of micro-nano powder:

[0044] Step 1: preparing BST sol;

[0045] Dissolve the precursors of Ba and Sr in hot glacial acetic acid to form a barium strontium precursor, mix butyl titanate with acetylacetone to form a titanium precursor, then mix the barium strontium precursor and titanium precursor, and then use glacial acetic acid to adjust The pH value of the mixed solution is between 3 and 4, and finally the BST sol of 0.2 to 0.4 M is obtained by constant volume with ethylene glycol methyl ether, wherein the molar ratio of Ba, Sr and Ti is 0.6:0.4:1; the Ba and Sr The precursor is acetate or nitrate of Ba and Sr; the amount of acetylacetone is 1.5 to 2.5 times the molar amount of butyl titanate;

[0046] Step 2: Dry the BST sol obtained in step 1 at 80-120°C to form a gel; then sinter the gel at 750-900°C for 180-240 minutes, and then cool naturally to obtain undoped BST micro-nano powder .

...

Embodiment 2

[0048] Embodiment 2: the preparation of adding 0.75% mol ratio citric acid BST micro-nano powder

[0049] Step 1: preparing BST sol;

[0050] The precursors of Ba and Sr are dissolved in hot glacial acetic acid to form a barium strontium precursor solution, and butyl titanate is mixed with acetylacetone to form a titanium precursor solution, then the barium strontium precursor solution and the titanium precursor solution are mixed, and the equivalent of Ti is added at the same time 0.75% citric acid in molar amount, then use glacial acetic acid to adjust the pH value of the mixed solution to between 3 and 4, and finally use ethylene glycol methyl ether to obtain 0.2 to 0.4M BST sol, in which Ba, Sr and Ti The molar ratio is 0.6:0.4:1; the precursors of Ba and Sr are acetates or nitrates of Ba and Sr; the amount of acetylacetone is 1.5 to 2.5 times the molar weight of butyl titanate;

[0051] Step 2: Dry the BST sol obtained in step 1 at 80-120°C to form a gel; then sinter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com