Resin composition and application thereof

A resin composition and resin technology are applied in the field of resin compositions for high-frequency and high-speed printed circuit boards, which can solve the problems of unsuitable high-frequency and high-speed printed circuit boards, lack of applications, etc., and achieve small rebound force, reduced dielectric loss, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] According to one aspect of the present invention, there is also provided a method for preparing a high-frequency high-speed printed circuit board solder resist protective layer, which includes the following steps: roll coating the above-mentioned resin composition to form a wet film; applying the wet film After pre-drying, heat roller lamination, exposure, development, and thermal curing are performed in sequence to obtain a solder resist protective layer. Using the above resin composition, the high-frequency and high-speed printed circuit boards (PCB, FPC, etc.) formed have lower dielectric constant and dielectric loss, and have good performance in heat resistance, bending property, rebound force, resolution and the like.

[0063] In a preferred embodiment, the thickness of the wet film is 25-50 μm; preferably, during the pre-drying process, the pre-drying temperature is 80-100 ° C, and the time is 15-30 min; Exposure energy is 100~500mJ cm -2 ; Preferably, in the dev...

Embodiment 1

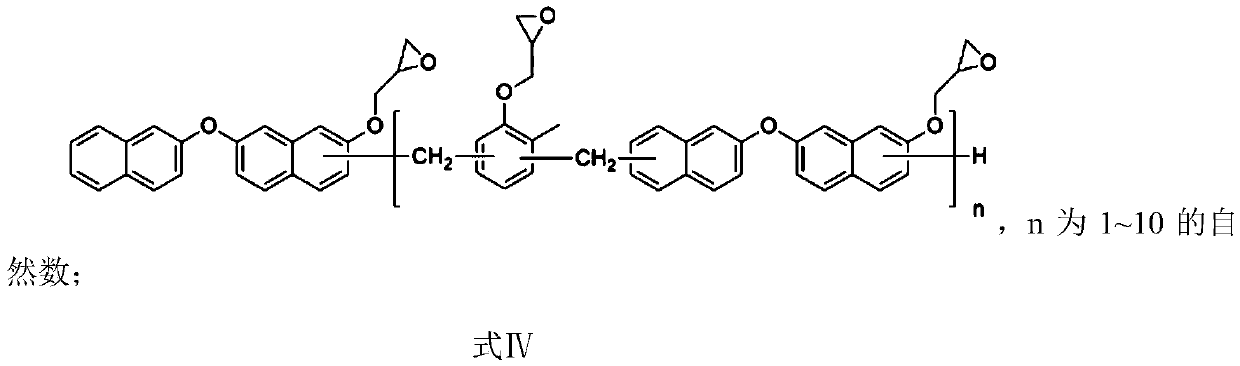

[0066] Preparation of a resin composition for high-frequency high-speed printed circuit boards: 15g alkali-soluble photosensitive epoxy acrylic resin ZAR-1035 (acid value 100mgKOH / g, solid content 64%), 2.5g acrylate monomer (wherein 1.5 g 20EOBPDMA, 1.0g 10EOTMPTA), 0.5g photopolymerization initiator (0.2g 184, 0.3g 907), 0.05g photosensitizer (ITX), 3.5g epoxy resin (2.7g naphthalene ring type low dielectric epoxy Resin, 0.8g toughened epoxy resin MX-154), 0.01g boron trifluoride ethylamine latent curing accelerator, 0.3g carbon black MA-7, 0.5g other additives (0.3g dispersant BYK168, 0.1 g leveling agent BYK 394, 0.1g defoamer BYK354), firstly grinded by three rollers, then stirred at high speed to dissolve and disperse, and finally filtered to obtain the glue solution, which was stored in dark light for later use.

Embodiment 2

[0068] Preparation of a resin composition for high-frequency high-speed printed circuit boards: 15g alkali-soluble photosensitive epoxy acrylic resin ZAR-1035 (acid value 100mgKOH / g, solid content 64%), 2.5g acrylate monomer (wherein 1.5 g 20EOBPDMA, 1.0g 10EOTMPTA), 0.5g photopolymerization initiator (0.2g 184, 0.3g 907), 0.05g photosensitizer (ITX), 3.5g epoxy resin (1.8g naphthalene ring type low dielectric epoxy Resin, 0.9g NPES-901, 0.8g toughened epoxy resin MX-154), 0.01g boron trifluoride ethylamine latent curing accelerator, 0.3g carbon black MA-7, 0.5g other additives (wherein 0.3 g dispersant BYK168, 0.1g leveling agent BYK 394, 0.1g defoamer BYK354), first grinded by three rolls, then stirred at high speed to dissolve and disperse, and finally filtered to obtain glue, and stored in dark light for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com