Rare earth oxide co-doped fluoride-free low-dielectric glass fiber and preparation method thereof

A low dielectric and glass fiber technology, applied in the field of fluorine-free low dielectric constant and low loss glass fiber, can solve the problems of high dielectric constant, easy to peel off, difficult wire drawing, etc., to achieve dielectric constant and dielectric loss Effects of reducing, preventing and limiting ion migration, increasing network density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

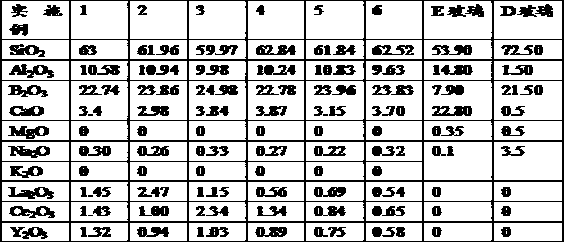

Embodiment 1~6

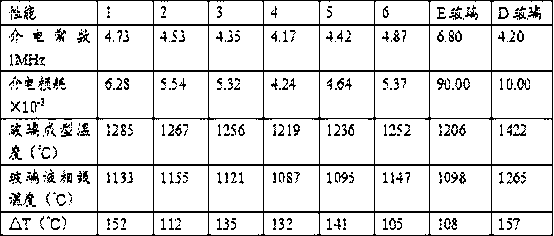

[0036] The raw material of the present invention can be made into glass or glass fiber. The method of preparing glass is to cast and anneal the molten glass obtained by melting raw materials; the method of preparing glass fiber is to draw the prepared molten glass on the basis of the drawing process. Since some test items cannot directly use glass fiber, in order to test the properties of glass fiber more conveniently, glass with the same formula is prepared for testing.

[0037] Remark:

[0038] 1. Dielectric properties: Use the Keysight E4990A precision impedance analyzer to measure the dielectric constant and dielectric loss of the sample at room temperature and 1MHz frequency;

[0039] 2. Glass forming temperature: use BROOKFIELD high temperature viscometer to test, take the glass liquid viscosity as 10 3 The temperature corresponding to Pa·S is the glass fiber forming temperature;

[0040] 3. Liquidus temperature: Use a TGA / DSC 1-1600HT differential scanning calorimete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com