Material composition of halogen-free printed circuit board with low dielectric loss and manufacturing method thereof

A printed circuit board and printed circuit technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of low dielectric constant, lack of low dielectric constant and low dielectric loss characteristics, and environmental pollution by flame retardants. , to achieve the effect of reducing the dielectric constant and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

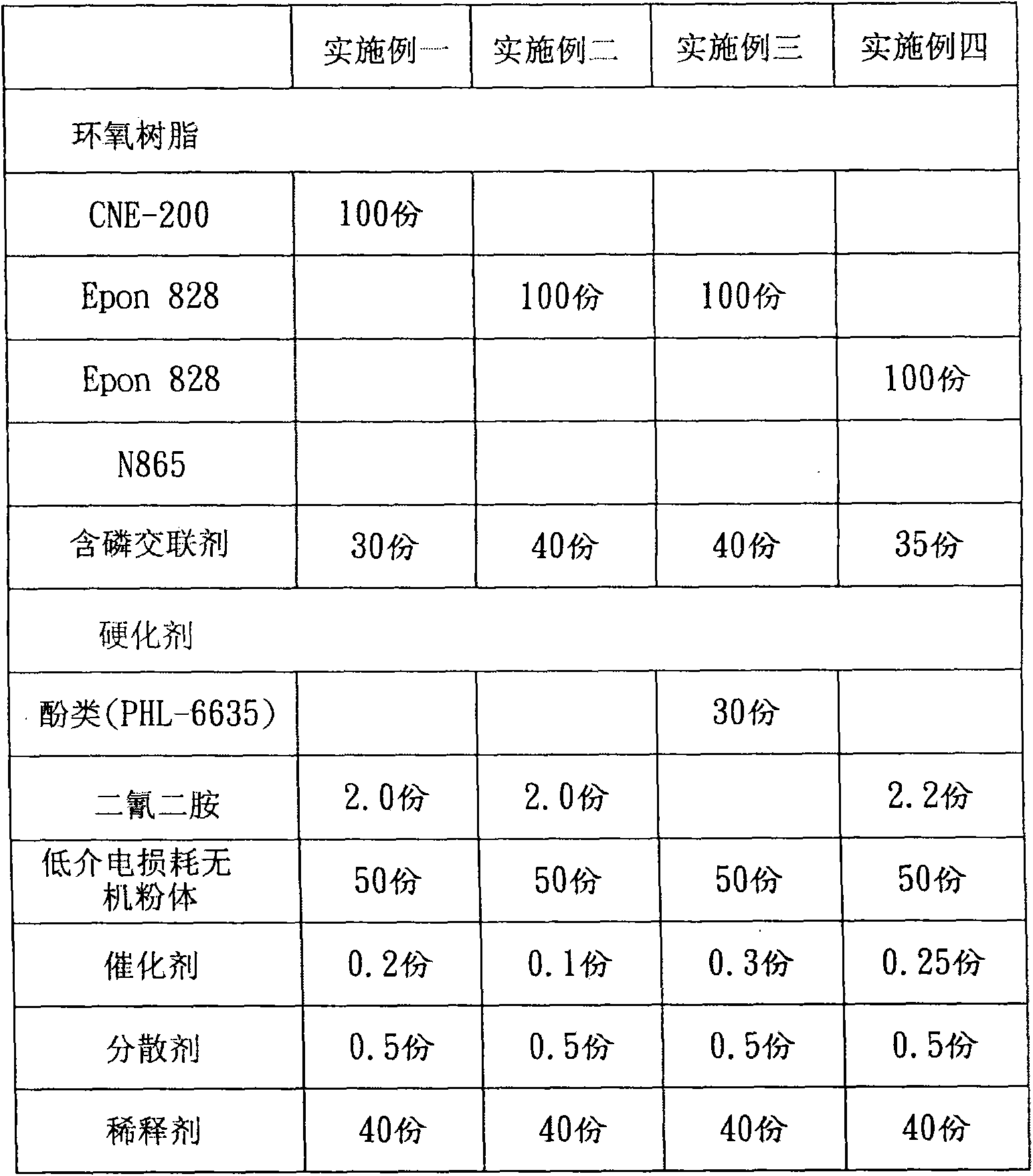

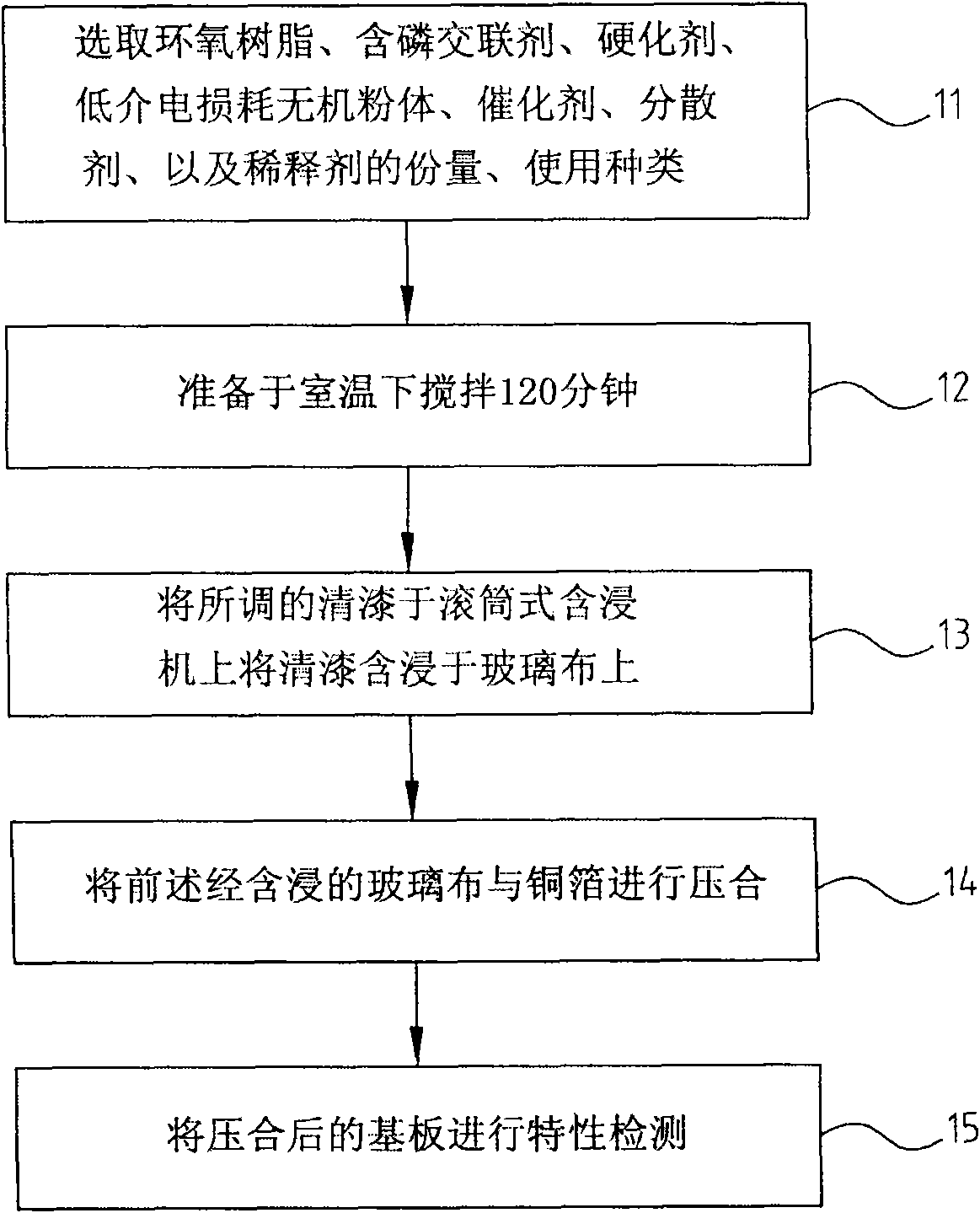

[0049]The invention relates to a composition and manufacturing method of a halogen-free printed circuit board material with low dielectric loss. The composition of the halogen-free printed circuit board material with low dielectric loss mainly includes:

[0050] 1. Epoxy resin: The epoxy resin used is halogen-free epoxy resin, including: phenolic epoxy resin, bisphenol epoxy resin, cyclopentadiene epoxy resin, polyurethane epoxy resin resin

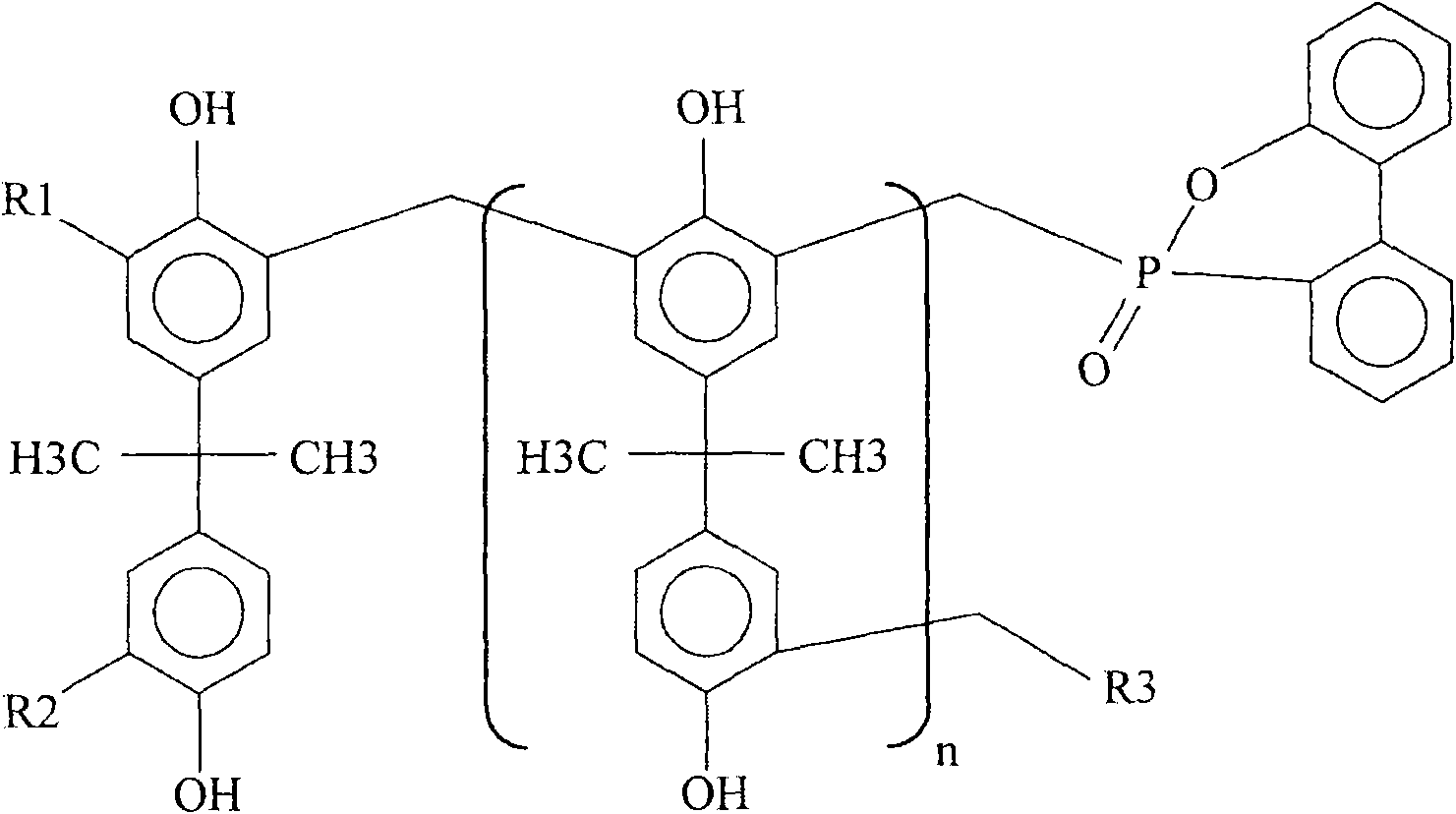

[0051] 2. Phosphorus-containing crosslinking agent: the phosphorus-containing crosslinking agent used is a reactive phosphorus-containing bisphenol A type crosslinking agent, wherein the phosphorus content of the phosphorus-containing crosslinking agent is 1 to 20%, and its molecular structure like figure 1 shown in . figure 1 It is a molecular structure diagram for illustrating the molecular structure of the phosphorus-containing crosslinking agent in the composition of the low dielectric loss halogen-free printed circuit board materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com