Copper clad laminate

A copper clad laminate and PTFE technology, used in high-speed transmission copper clad laminates and high frequency fields, can solve the problems of low dielectric constant, low dielectric loss, high sintering temperature, reduce dielectric constant and dielectric loss, and reduce production. cost, the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

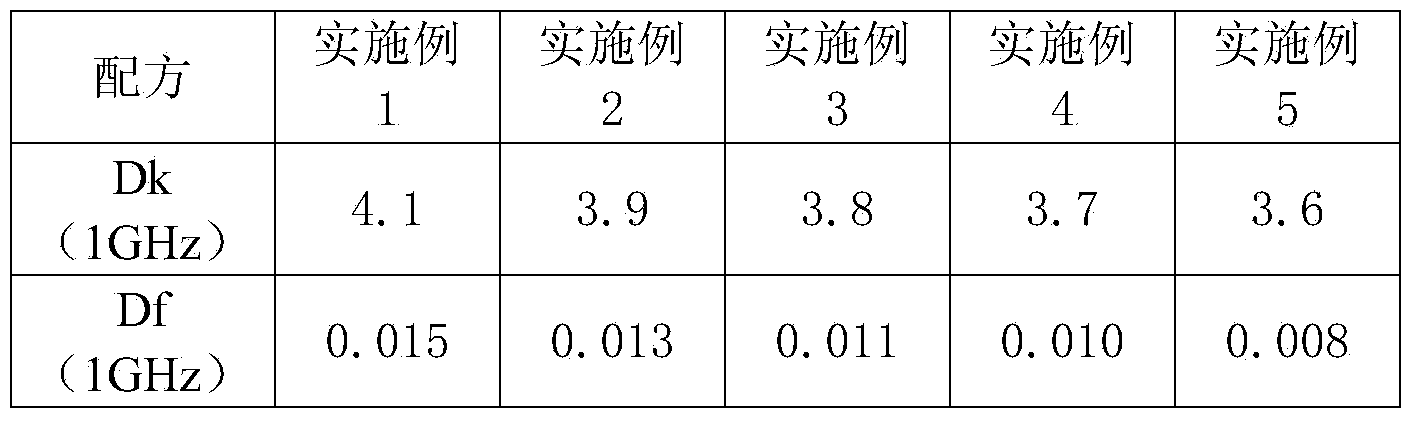

Embodiment 1

[0034] Weigh 80 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19wt%, product name DER530), 20 parts by weight of modified cross-linked PTFE resin (Dakin, Japan, The fluorine content is more than 24wt%, the hydroxyl value is 60, and the product name is GK-570), which is dissolved in butanone solution and prepared as 65wt% glue. 2116 glass fiber cloth is impregnated in the above glue; after heating and drying, it forms a semi-cured adhesive sheet , wherein the content of 2116 glass fiber cloth is 50wt%, and the content of thermosetting resin is 50wt%. This step can be repeated to prepare multi-layer adhesive sheets, place copper foil on both sides, pressurize and heat to form a copper clad laminate.

Embodiment 2

[0036] Weigh 60 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19wt%, product name DER530), 40 parts by weight of modified cross-linked PTFE resin (Dakin, Japan, The fluorine content is more than 24wt%, the hydroxyl value is 60, and the product name is GK-570), which is dissolved in butanone solution and prepared as 65wt% glue. 2116 glass fiber cloth is impregnated in the above glue; after heating and drying, it forms a semi-cured adhesive sheet , wherein the content of 2116 glass fiber cloth is 50wt%, and the content of thermosetting resin is 50wt%. This step can be repeated to prepare multi-layer adhesive sheets, place copper foil on both sides, pressurize and heat to form a copper clad laminate.

Embodiment 3

[0038]Weigh 50 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19wt%, product name DER530), 50 parts by weight of modified cross-linked PTFE resin (Dakin, Japan, The fluorine content is more than 24wt%, the hydroxyl value is 60, and the product name is GK-570), which is dissolved in butanone solution and prepared as 65wt% glue. 2116 glass fiber cloth is impregnated in the above glue; after heating and drying, a prepreg adhesive sheet is formed. , wherein the content of 2116 glass fiber cloth is 50wt%, and the content of thermosetting resin is 50wt%. This step can be repeated to prepare multi-layer adhesive sheets, and copper foil sheets are placed on both sides, and pressurized and heated to form a copper clad laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com