Thermosetting resin composition as well as prepreg and laminated board manufactured by utilizing same

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., and can solve the problems of decreased moisture and heat resistance and dielectric properties, increased water absorption of cured products, poor anhydride reactivity, etc. problem, to achieve the effect of reducing the dielectric constant and dielectric loss, increasing the glass transition temperature, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0034] Examples and comparative examples:

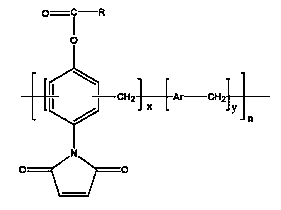

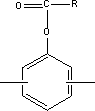

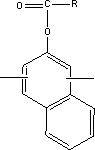

[0035] Examples 1 to 3 are the synthesis of the active ester resin of the present invention, Comparative Examples 1 to 2 are the synthesis of ordinary phenolic type active ester resins, Examples 4 to 8 and Comparative Examples 3 to 4 are the preparation and physical property evaluation of thermosetting resin compositions . Unless otherwise specified below, "parts" means "parts by weight", and "%" means "% by weight".

Embodiment 1

[0037] Put N-(4-hydroxyphenyl)maleimide (40g, 0.21mol), phenol (160g, 1.70mol) and oxalic acid (10g) into the flask equipped with thermometer, condenser and stirrer, mix and stir After uniformity, place it in a constant temperature water bath at 70°C; then, with stirring, add formaldehyde solution (125 mL, phenol / aldehyde ratio 1 / 0.8) to the flask dropwise over 0.5 hours. After the formaldehyde is added, the temperature and stirring conditions are maintained at 70°C to react for 15 hours. Then, the reaction product was dissolved and diluted with 400 mL of acetone, and then the reaction product was precipitated with a 40% methanol aqueous solution. Repeat the above dissolution-precipitation operation 3 to 5 times, filter, separate, and dry to obtain a pure nitrogen-containing polyfunctional phenol compound.

[0038] Take 130 g of the polyfunctional phenol compound prepared by the above method and 500 g of the methyl isobutyl ketone solvent and put them in a flask to fully mix and...

Embodiment 2

[0043] Put N-(4-hydroxyphenyl)maleimide (80g, 0.42mol), phenol (120g, 1.28mol) and oxalic acid (10g) into a flask equipped with thermometer, fractionator, condenser, and stirrer , After mixing and stirring, place in a constant temperature water bath at 70°C. Then, under stirring, a formaldehyde solution (110 mL, 37% aqueous formaldehyde solution, phenol / aldehyde ratio 1 / 0.8) was added dropwise to the flask over 0.5 hours. After the formaldehyde is added, the temperature and stirring conditions are maintained at 60°C to react for 15 hours. Next, the reaction product was dissolved and diluted with 500 mL of acetone, and then the reaction product was precipitated with a 40% methanol aqueous solution. Repeat the above dissolution-precipitation operation 3 to 5 times, filter, separate, and dry to obtain a pure nitrogen-containing polyfunctional phenol compound.

[0044] Take 142 g of the polyfunctional phenol compound prepared by the above method and 600 g of the methyl isobutyl ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com