Composite low-pressure casting riser tube and preparation method thereof

A low-pressure casting, riser technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of poor mechanical properties, corrosion wear, riser wear and other problems of the riser, to prevent aluminum The problem of iron infiltration in liquid, the effect of improving surface adhesion and improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The invention also discloses a method for preparing a composite low-pressure casting riser, which is specifically as follows:

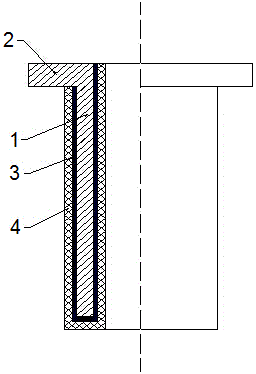

[0019] (1) Use casting technology to prepare a substrate with a wall thickness of 3-12 mm, and perform deburring and flashing treatment on the inner and outer surfaces of the substrate 1. After the treatment is completed, perform sandblasting and roughening on the surface of the substrate 1, wherein the particle size of the sand is 0.5 ~1.4mm, the surface roughness of substrate 1 is 2.5~13.0;

[0020] (2) Preheat the substrate 1 to 50-150°C. After the preheating is completed, use thermal spraying technology to spray the transition layer 3 on the inner and outer surfaces of the substrate 1, and control the spraying voltage of the spraying device to 65-80V and the current to 500-700A. The air pressure is 0.1-0.25MPa, and the spraying distance from the surface of the substrate 1 is 40-70mm;

[0021] (3) Continue to use the thermal spraying device...

Embodiment 2

[0026] The invention also discloses a method for preparing a composite low-pressure casting riser, which is specifically as follows:

[0027] (1) Use casting technology to prepare a substrate with a wall thickness of 3-12 mm, and perform deburring and flashing treatment on the inner and outer surfaces of the substrate 1. After the treatment is completed, perform sandblasting and roughening on the surface of the substrate 1, wherein the particle size of the sand is 0.5 ~1.4mm, the surface roughness of substrate 1 is 2.5~13.0;

[0028] (2) Preheat the substrate 1 to 150-250°C. After the preheating is completed, use thermal spraying technology to spray the transition layer 3 on the inner and outer surfaces of the substrate 1, and control the spraying voltage of the spraying device to 65-80V and the current to 500-700A. The air pressure is 0.25-0.4MPa, and the spraying distance from the surface of the substrate 1 is 70-120mm;

[0029] (3) Continue to use the thermal spraying devi...

Embodiment 3

[0034] The invention also discloses a method for preparing a composite low-pressure casting riser, which is specifically as follows:

[0035] (1) Use casting technology to prepare a substrate with a wall thickness of 3-12 mm, and perform deburring and flashing treatment on the inner and outer surfaces of the substrate 1. After the treatment is completed, perform sandblasting and roughening on the surface of the substrate 1, wherein the particle size of the sand is 0.5 ~1.4mm, the surface roughness of substrate 1 is 2.5~13.0;

[0036] (2) Preheat the substrate 1 to 250-350°C. After the preheating is completed, use thermal spraying technology to spray the transition layer 3 on the inner and outer surfaces of the substrate 1, and control the spraying voltage of the spraying device to 65-80V and the current to 500-700A. The air pressure is 0.4-0.5MPa, and the spraying distance from the surface of the substrate 1 is 120-160mm;

[0037] (3) Continue to use the thermal spraying devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com