Bush with metal ceramic composite structure for flat-die biomass molding machine and growing method of aluminum oxide ceramic layer

A biomass forming machine and metal-ceramic composite technology, which is applied in anodizing, presses, manufacturing tools, etc., can solve the problems of high manufacturing cost, short service life, poor wear resistance, etc., and achieve good wear resistance and long life Improvement and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

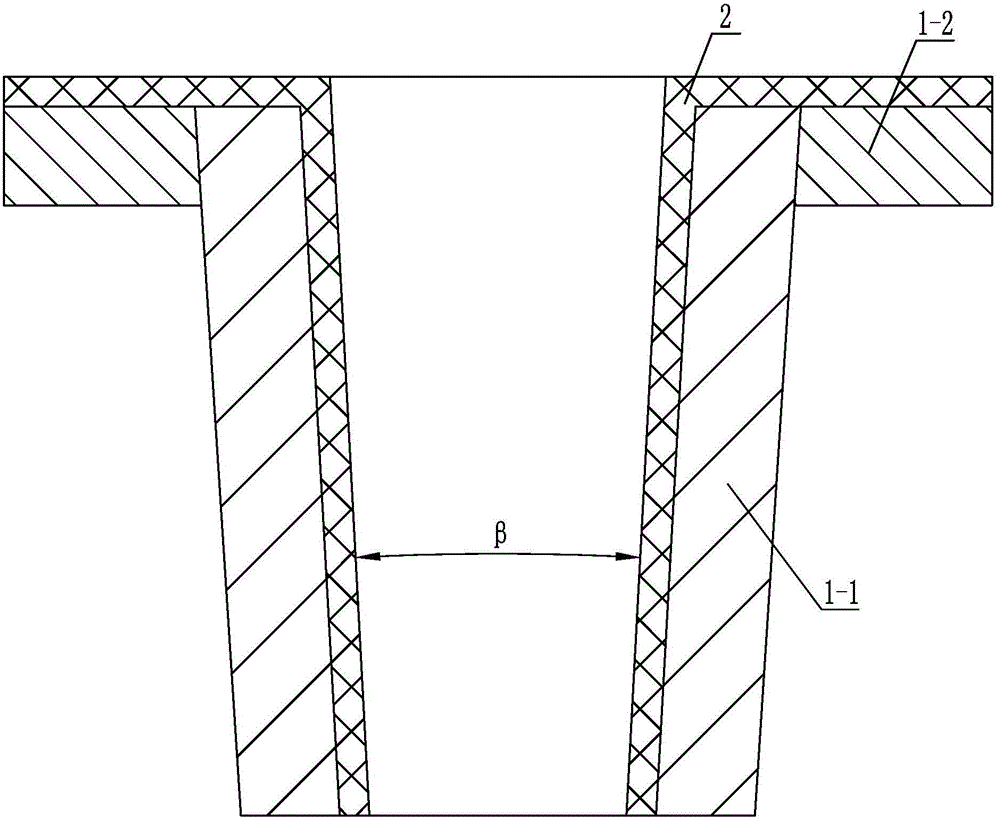

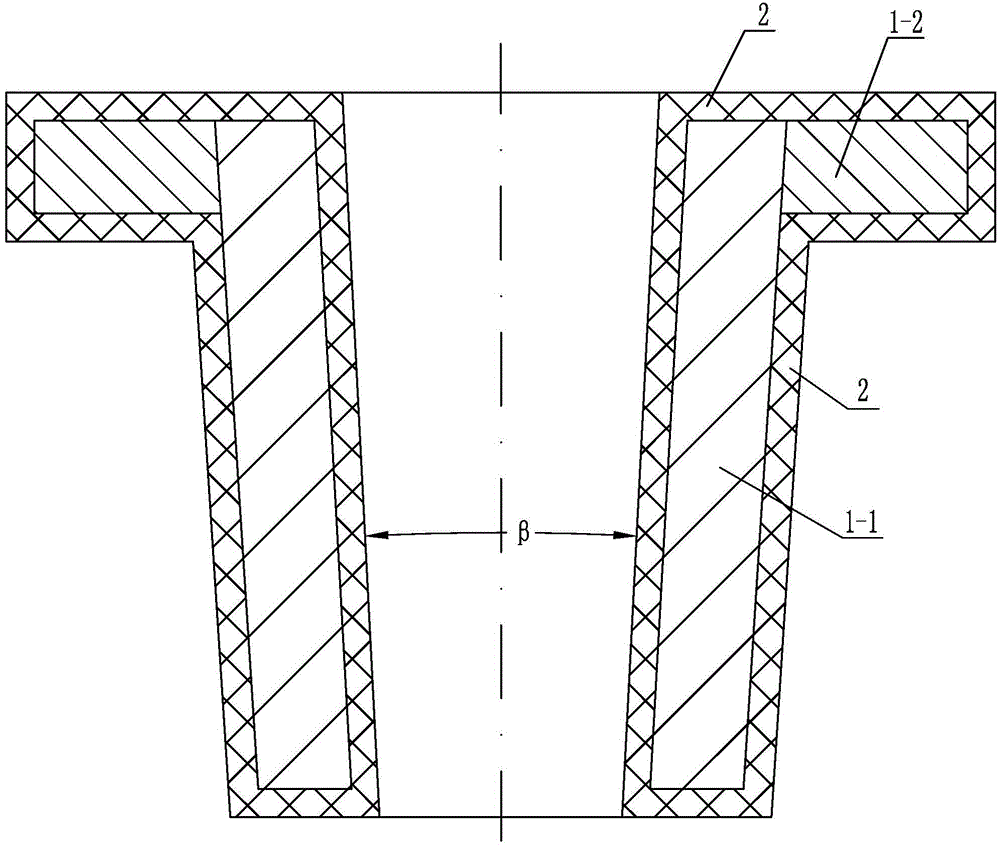

[0017] Specific implementation mode one: combine Figure 1-Figure 3 Illustrate that a metal-ceramic composite structure bushing for a flat-die biomass molding machine in this embodiment is mainly composed of a base body 1 and an alumina ceramic layer 2 on the surface of the base body; the base body 1 is mainly made of an integrated hollow tapered sleeve 1-1 and ring sleeve 1-2, the outer surface of the large diameter end of the hollow tapered sleeve 1-1 is fixedly connected with a ring sleeve 1-2, the upper surface of the hollow tapered sleeve 1-1 and the ring sleeve 1-2 The upper surface of the substrate 1 is flush with each other, and the surface of the substrate 1 is oxidized by micro-arc to form an alumina ceramic layer 2. The substrate 1 is made of aluminum or aluminum alloy, and the thickness of the alumina ceramic layer 2 is 40 microns to 130 microns.

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-Figure 3 Note that the aluminum alloy described in this embodiment is LC9 aluminum alloy or LY12 aluminum alloy. With such setting, the hardness is high, the composition is reasonable, the comprehensive performance is good, and it can be strengthened by heat treatment. Others are the same as in the first embodiment.

specific Embodiment approach 3

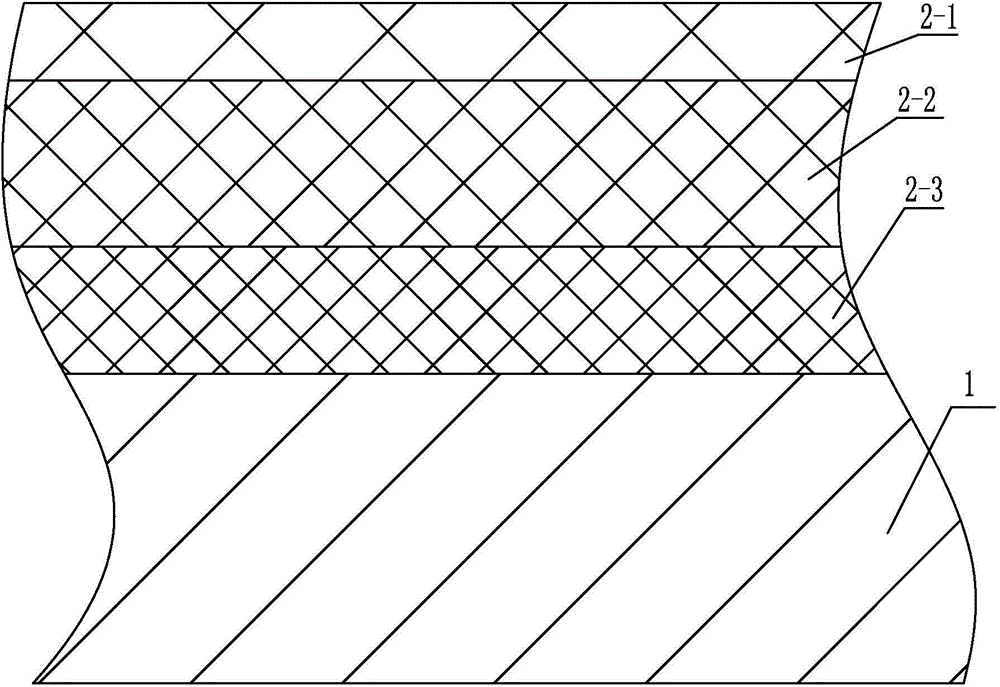

[0019] Specific implementation mode three: combination figure 1 Note that the alumina ceramic layer 2 in this embodiment is mainly composed of a loose layer 2-1, a dense layer 2-2 and a transition layer 2-3, and the dense layer 2-2 is located between the loose layer 2-1 and the transition layer 2-3 In between, the transition layer 2-3 is set against the base 1. In this way, the loose layer is exposed to the dense layer after being worn out, and the dense layer has high hardness and wear resistance and can resist the wear of the material. Therefore, it can not only overcome the problems of severe wear and low service life of the integral metal bushing, but also solve the problem that the integral ceramic material cannot guarantee the machining accuracy and is easily broken. Others are the same as in the first or second embodiment.

[0020] Specific implementation mode four: combination Figure 2-Figure 3 Note that the alumina ceramic layer 2 in this embodiment is mainly comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com